Results 1 to 10 of 14

Threaded View

-

08-18-2013, 08:03 PM #1

Well Ive taken the first steps of practice. Its not much but Im excited to do more.

Well Ive taken the first steps of practice. Its not much but Im excited to do more.

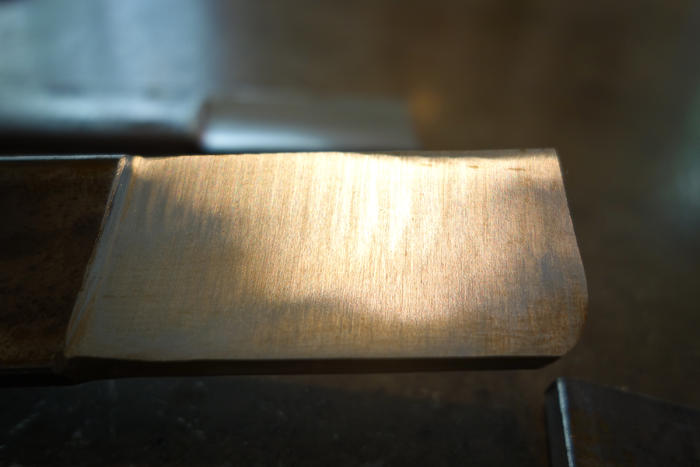

All of these are crap flat rod I picked up at Home Depot after reading a post from Lewis recommending people practice using it when they learn to use a belt grinder.

Im glad I listened. It worked perfectly and clearly showed where I was uneven and leaving facets. I have alot more practice to do before I would feel comfortable taking it to quality steel.

Try 1:

Try 2:

Try 3:

This stuff rusts crazy fast luckily this isnt what razors are made of or everyones would be rusted to hell. For three hours of play and experimentation Im pretty happy, and terribly excited to practice more and get the grinding process down. Thanks for all the people who have posted helpful tips that I picked up on randomly.

Thanks for all the people who have posted helpful tips that I picked up on randomly.

10Likes

10Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote