Results 1 to 8 of 8

18Likes

18Likes

Thread: Razor forging/fabrication article from 1852.

-

12-03-2013, 01:39 PM #1Historically Inquisitive

- Join Date

- Aug 2011

- Location

- Upstate New York

- Posts

- 5,782

- Blog Entries

- 1

Thanked: 4249 Razor forging/fabrication article from 1852.

Razor forging/fabrication article from 1852.

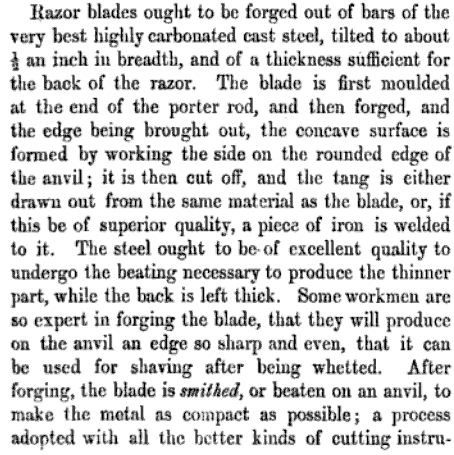

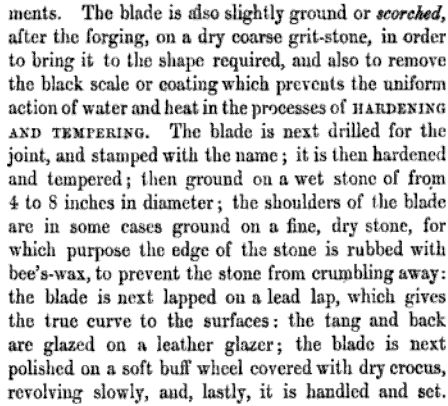

Razor forging/fabrication article from The encyclopedia of useful arts, 1852.

-

The Following 11 Users Say Thank You to Martin103 For This Useful Post:

-

12-03-2013, 01:46 PM #2

Well there is something to try

Last edited by Ludvig; 12-03-2013 at 01:49 PM.

-

12-03-2013, 04:20 PM #3

Interesting read. Thanks! Interesting to see that they hollowed the blade on the anvil.

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

12-04-2013, 03:38 AM #4Bladesmith by Knight

- Join Date

- Jun 2007

- Location

- Murrumba Downs, Queensland, Australia.

- Posts

- 571

Thanked: 203

If i remember correctly i think that is what Charlie does. i was toying with making a fullering tool to achieve the same outcome but more quickly and evenly than i have managed on the anvil horn as it tapers. Charlie's is a small square anvil with curves off the surface for the razor hollows.

Regards

-

12-07-2013, 08:05 PM #5Senior Member

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1184

I have to start forging blades (need to build a grinder) but I was thinking that shaping the hollow was the best part to learn. The more shaping when yellow hot the better. I guess I am looking forward to using the hammer more than the grinder.

Good judgment comes from experience, and experience....well that comes from poor judgment.

-

12-07-2013, 08:31 PM #6

In theory, yes. But give it a try

You'll see it is much harder than you might think. In particular, making an even hollow without dents and scars, keeping it symmetrical is difficult. And then you have to allow for the fact that hammering -> scarring and some pitting. You need enough left to grind all of the scarring unevenness, dents away.

You'll see it is much harder than you might think. In particular, making an even hollow without dents and scars, keeping it symmetrical is difficult. And then you have to allow for the fact that hammering -> scarring and some pitting. You need enough left to grind all of the scarring unevenness, dents away.

Generally, After forging I end up with a triangular wedge that is perhaps just a bit thinned in the middle. After that the grinder does the work.Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

12-07-2013, 09:40 PM #7Senior Member

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1184

Yeah I can imagine all the pitfalls in hammering one out but imagine taking the time to get that good at it. It wouldn't hurt to make a special hammer and hardy tool to accomplish this which would help eliminate some of those pitfalls. I would think the design/shape of the razor would have a lot to do with being successful also. By saying it is a tough go you have made me want to try it even more. Well when I finally get the time to finish the prep, which is finishing my forge and getting my anvil set.

Good judgment comes from experience, and experience....well that comes from poor judgment.

-

12-07-2013, 10:23 PM #8

Well, you can try to hammer it out, but you need a hammer and hardie that are properly shaped.

However, The much better way would be to use a shaped die that you can hammer a yellow hot blank into.

The would solve the problem of variance between hammer strokes, and maximize the amount of work you get done with eacht heat.

You'd probably need a set of dies that progressively change from square to hollow.

Even so, you still need to leave enough meat (thickness) around the edge to prevent warp during heat treatment and enough material to remove in grinding. Even with forging the hollow, you still need quite a 'meaty' blank. Come to think of it: if you have a hollow ground solingen razor with shoulders, you can see it. The shoulders are how 'fat the razor was before it was heat treated.Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

The Following User Says Thank You to Bruno For This Useful Post:

Slawman (09-12-2016)

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote