Results 1 to 10 of 27

Thread: New forge build!!

-

01-23-2014, 04:45 AM #1

New forge build!!

My friends call me Bear.

New forge build!!

My friends call me Bear.

-

The Following 3 Users Say Thank You to PierreR For This Useful Post:

MileMarker60 (01-23-2014), ScottGoodman (01-23-2014), spazola (01-23-2014)

-

01-23-2014, 05:20 AM #2Senior Member

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1184

Very nice build !

Good judgment comes from experience, and experience....well that comes from poor judgment.

-

01-23-2014, 06:06 AM #3Poor Fit

- Join Date

- May 2010

- Posts

- 4,562

Thanked: 1263

I have a distinct feeling I'm gonna have to make a trip to Lloyd this summer...lol. Looks pretty cool Pierre.

-

01-23-2014, 10:45 AM #4

Awesome industrial strength looking setup there

Can't wait to see what you make with itSaved,

to shave another day.

-

01-23-2014, 10:59 AM #5

Great work

Out of curiosity, what does it cost to put something like this together?

-

01-23-2014, 01:48 PM #6

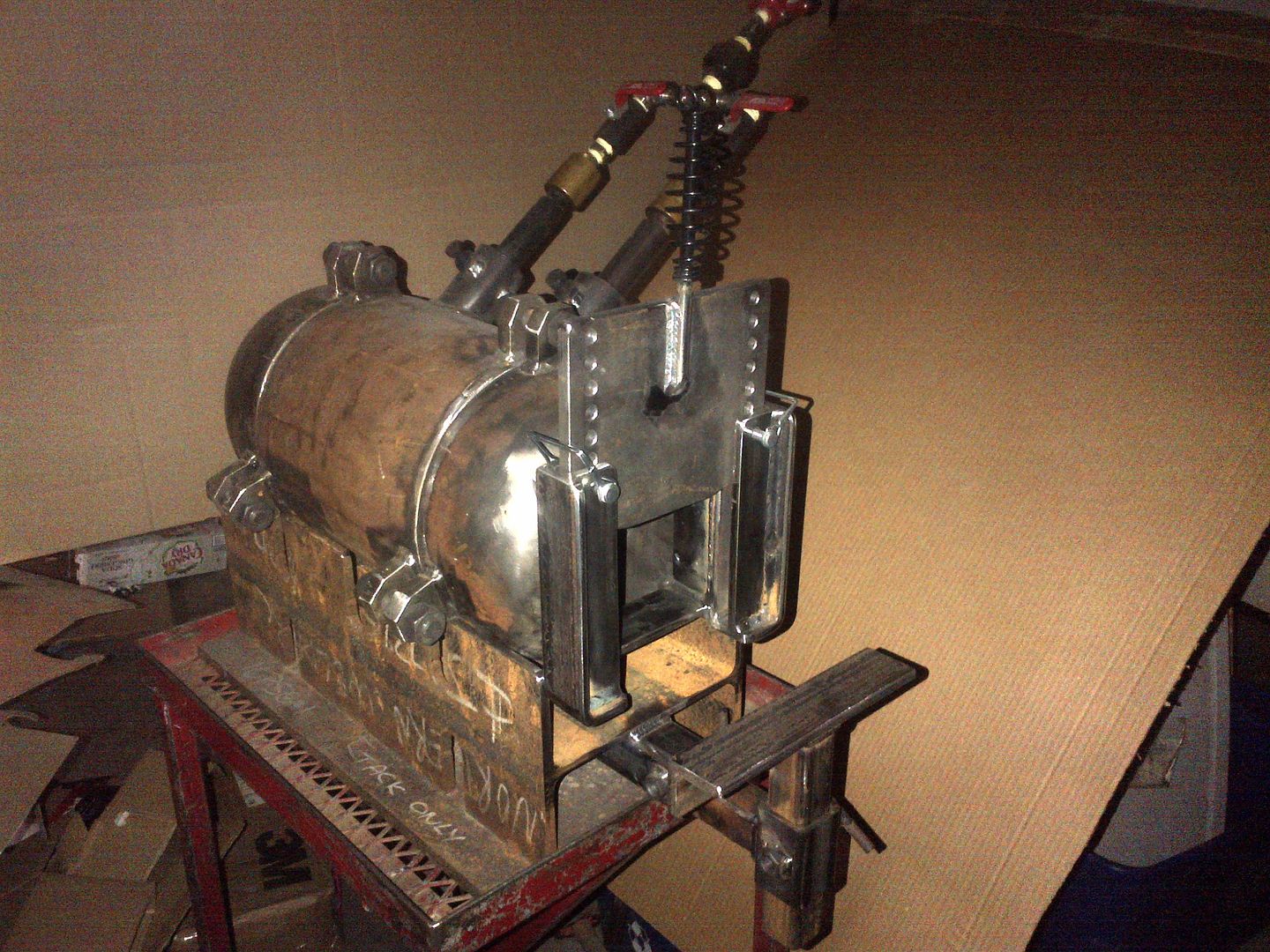

All components of the build are salvaged scrap except the burners. The main body is a piece of 12" dia heavy wall pipe (1/2" wall) The end caps are 5/8" thick and come from a pipe line job I surveyed, it is the component that is welded to the end of a pipe that gets pulled through a bore hole on a river crossing (they pre drill/bore a hole under a river, attach a cable to the bit on the other side, pull the bit out, attach the cable to the pipe, and pull it through, the cap keeps dirt out of the pipe.) A friend helped with the welding. My hunting buddy is a gas fitter, so I had solid assistance there. Each burner comes from a fire tube that keeps a 750 barrel tank (15'6" dia x 30' tall) of heavy crude oil (Picture a cross between tar and molasses) in a liquid state in our -40C winters. Door slide and hardware are scrap, 3/8" thickness angle iron and 1/2" plate.

So cost... A hunting knife and a kitchen knife! lol!! If you had to pay for components, and welding, valves, regulator etc., I don't think you could do it under $650-$700. Depends on what you can source. bul look here... Zoeller Forge Home Page Gas Forge parts, Atmospheric Burners, and Blacksmithing You can do very well for a fraction of this build!My friends call me Bear.

-

The Following 3 Users Say Thank You to PierreR For This Useful Post:

AndrewJM (01-23-2014), Catrentshaving (01-23-2014), skipnord (01-23-2014)

-

01-23-2014, 02:03 PM #7

Thank you for the pictures, it looks like a delux build, very nice.

Charlie

-

01-23-2014, 02:08 PM #8

Thanks Pierre,

I'd love something like that, but personally would be hard to justify the cost. If I could do it for 500 Id give it a go, just for fun and a hobby, but because I wouldn't get any financial return it would be a bit too much. Also, its not just the cost of the furnace, but the anvil etc. Unless I could rent out use to other interested parties, but I don't know where Id find people. I have heaps of space under my house, but isn't legal height so my lawyer wouldn't let me do that (my old man is a lawyer and Id never hear the end of it if I rented the use to 3rd parties in a space that wasn't legal height)

Awesome product, Im quite jealous Well, someday... maybe I have to move to Nigeria and start selling razors and supplies to all these honest and trustworthy fine folk here

Well, someday... maybe I have to move to Nigeria and start selling razors and supplies to all these honest and trustworthy fine folk here  Plus Im pretty sure I work for a bank and have a $12 million estate which I can't find the beneficiaries for... but they said their grandchild was a member here, and for the low price of $5k I could arrange for the funds to be transferred to them

Plus Im pretty sure I work for a bank and have a $12 million estate which I can't find the beneficiaries for... but they said their grandchild was a member here, and for the low price of $5k I could arrange for the funds to be transferred to them  That would raise some cash lol.

That would raise some cash lol.

AndrewLast edited by AndrewJM; 01-23-2014 at 02:13 PM.

-

01-23-2014, 02:55 PM #9aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

Nice and heavy build, should last a lifetime. I have a question on your burners. Are the copper components flashback protectors or where the O2 mixes with the gasses. I ask this because I thought you would need to mix the air & gas before you get it to the forge container as your forge looks mostly airtight.

You might heat and bend the handle for the door back over the forge body as I have a feeling it will get HOT if you are running the forge with the door open.

Again, really, really nice build. Wish I could have done that!Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

01-23-2014, 04:07 PM #10

I will try to get a couple better pictures of the brass Venturi. There are three holes, 120* apart! at 60*. They aim directly at the end of the orface which is in the end of the mixer. The black pipe is the mixing chamber, and there is a flare on the end, which has the main flame out the centre, plus a starburst diffuser to hopefully reduce hot spots. The burners are tangential to the proposed castable liner.

My friends call me Bear.

-

The Following User Says Thank You to PierreR For This Useful Post:

ScottGoodman (01-23-2014)

23Likes

23Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote