Results 21 to 30 of 32

Thread: Today's accomplishments

-

01-18-2015, 04:42 AM #21

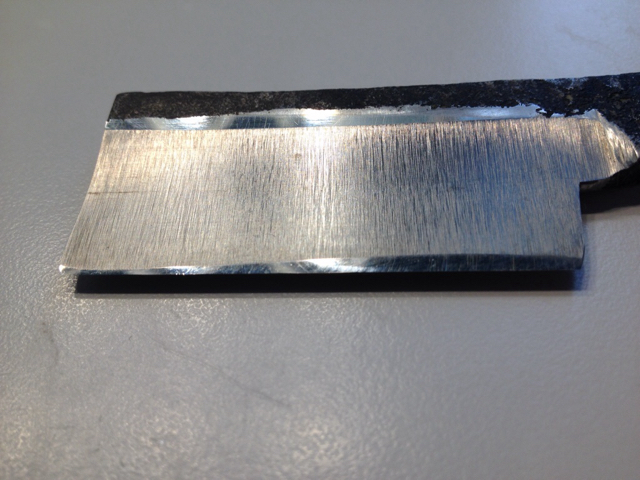

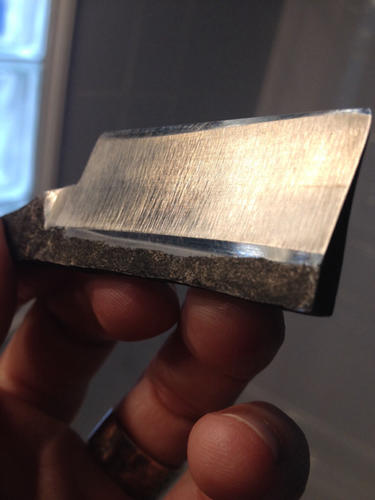

Couldn't get an edge to stay on this homebrew one-piece razor. I'm starting to wonder if I did in fact over-temper it. I went all the way from bevel set to using my new little nakayama asagi and kiita nagura three times. Edge wouldn't hold after a solid hour or so of honing. I couldn't see any evidence of over-honing (other than the timeframe) but the edge seemed to roll and flake into sparkly crap, so maybe it was over-honed.

This may be a RSO for the learning books, but I may try once more with two layers of tape just in case.

Last edited by Atchbo; 01-18-2015 at 03:05 PM.

-

01-19-2015, 04:24 AM #22

Yep. Either the geometry is too narrow or the steel is soft.

One pass at my burns and the edge fails.

On a lighter note, the combination of Chosera 1k, hideriyama suita and Nakayama asagi with kiita tomo nagura seem to work great! Will try another example on known steel.

-

01-19-2015, 06:54 AM #23

What is the geometry? spine thickness vs blade width?

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

01-20-2015, 04:45 AM #24

I don't have it in front of me, but it started out as 1/4" bar and was thinned while forging to about 3/16" and the blade is about 1". I know that's too long/narrow. I may go all the way back to the grinder and take it down another step.

-

01-20-2015, 07:06 AM #25

It could still be a combination of issues, but Imo that's way too thin to support a good edge.

At 3/16 thickness, that should not be wider than a 6/8.

If you work with bar stock that is 1/4 thick, you can upset it first, and then forge it wedge shaped. That way the spine will be thicker and the geometry will be much easier to get right.Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

The Following User Says Thank You to Bruno For This Useful Post:

Atchbo (01-21-2015)

-

01-21-2015, 01:50 AM #26

Why didn't I think of that?

-

01-22-2015, 11:47 PM #27aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

That's how we learn my friend. The kick in the seat is when you forget/don't do something and repeat a error, that's frustrating!

Spend some time at the grinder and get it down to a smaller razor. The benifit will be a super thin bevel and the challenge will be not getting things too hot to kill the HT. Good practice no matter if it comes out to a razor or rso, win-win! I have made plenty of rso's, they just don't make it on here very often...Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

01-25-2015, 07:16 PM #28

In the end, I think this razor is looking better with a narrower blade anyway. It was just too long to start.

I will post pics later.

I also learned today that it is better to drill all the holes in scales before separating them and test-fitting the wedge. I drilled googly eyes in my first set of horn scales for another razor in this series (double pins on the wedge end are crooked).

-

02-07-2015, 09:36 PM #29

Fitted some pins today. This razor was started something like 2 years ago. Better late than never! Last one from that first batch.

Needs to be tightened at the pivot pin and another coat of lacquer or polish.

-

02-07-2015, 09:45 PM #30

Also got this one to shave. For some reason I still could not sharpen this forged O1 except on my diamond film. At least I know now that the steel can survive a shave.

29Likes

29Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote