Results 11 to 20 of 35

-

02-22-2015, 07:23 PM #11aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

And it has a tight looking grain too. Do you happen to remember how you HT'd it?

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

02-22-2015, 07:59 PM #12

Last edited by MileMarker60; 02-22-2015 at 08:07 PM.

-

02-22-2015, 08:01 PM #13

A very interesting thread. Thanks for sharing.

-

02-23-2015, 08:49 AM #14

When I get home I'll break some stuff as well.

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

02-24-2015, 12:00 AM #15

Robeson shuredge

Franklin C Co., Germany

Interesting note to the Franklin.

It has a ton of hone wear. It was basically wasted. Typically when I see a ton of hone wear I assume really heavy use.

The question that popped in my head after breaking it was:

Did the large amount of hone wear come from heavy use or was the razor prone edge chipping.

-

The Following 2 Users Say Thank You to MileMarker60 For This Useful Post:

gregg71 (02-24-2015), ScottGoodman (02-24-2015)

-

02-24-2015, 11:18 AM #16

Love the fine train of the shuredge

Saved,

to shave another day.

-

02-24-2015, 03:41 PM #17aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

Does make you wonder if the wear is from having to hit the stones regularly or as you said being chippy. Real nice grain structure in the Robeson.

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

02-25-2015, 06:07 PM #18Senior Member

- Join Date

- Feb 2015

- Location

- Florida

- Posts

- 507

Thanked: 49

-

02-27-2015, 09:56 PM #19

Ok here are a couple I had lying around and they had no better purpose in life anymore than to be broken except for the last one.

This one is an M George and Son(s?). 6/8 wedge of horrible quality. The tang was not in the same plane as the blade, the tail looked chewed off. This was imo the zeepk of sheffield. Looks grainy and it didn't break clean at all.

This was a 5/8 wostenholm ixl. it was warped so I decided to break it since it wasn't good for anything else due to the warp. This one is better than the George, but still not hugely impressed. The grain looks un-even. Perhaps this is related to the warp.

Then a general solingen razor. The tang is covered in rust and I can't read the tang stamp. It snapped very clean, and the grain looks very fine. Noticeable different from the 2 solingen razors.

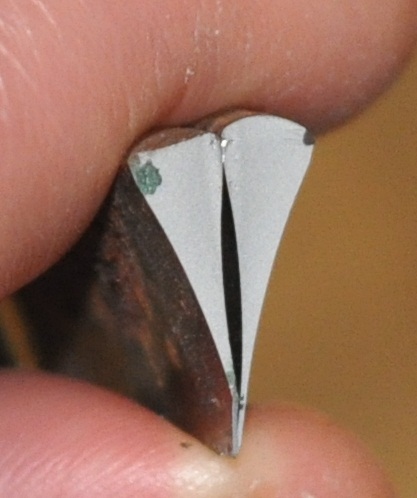

And this is the Dracula razor I made for TC almost a year ago or so. It is O2 steel with forge welded inserts. All heat treatment done in charcoal fire, with temperature gauged by color. It was not broken on purpose of course. In a freak accident it fell after being put in the safe and when the door went shut, the door proved to be stronger. The break seems very neat and the grain looks small and even.

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

The Following 5 Users Say Thank You to Bruno For This Useful Post:

gregg71 (02-28-2015), JDM61 (02-27-2015), MileMarker60 (03-02-2015), ScottGoodman (02-28-2015), WW243 (02-28-2015)

-

02-27-2015, 10:28 PM #20Senior Member

- Join Date

- Feb 2015

- Location

- Florida

- Posts

- 507

Thanked: 49

Noticeable difference especially when comparing yours and the last factory one to the first.

39Likes

39Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote