Results 1 to 10 of 26

Hybrid View

-

03-07-2015, 07:27 PM #1Senior Member

- Join Date

- Feb 2015

- Location

- Florida

- Posts

- 507

Thanked: 49 blade width vs, thickness question.

blade width vs, thickness question.

In some ways this seems kind of obvious, but as a newbie, i can't fall into that trap. From what I have gathered from the very helpful folks on this forum, the ratio of width of the blade should be at least 3.5 times if not closer to 4 times the thickness of the spine so as to get a proper edge bevel angle when using he spine as the "honing guide." I would think that this would mean measured from the lowest part of the "spine" or flat part of the blade that makes contact with the stone, correct? I ask because I see pics of some very nice, fancy razors that have wedged along the spine, so the point of contact with the stone for purposes of measurement would be the "rib" running below the spine.

-

03-07-2015, 09:59 PM #2

The correct way to measure, for the purpose of geometry, is from the edge to the point where the spine makes contact with the hone. At that point, the thickness vs width (edge to spine contact) should be at least 1/4, and preferably a bit higher still, like 1/3.5

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

03-08-2015, 12:12 AM #3Senior Member

- Join Date

- Feb 2015

- Location

- Florida

- Posts

- 507

Thanked: 49

Thanks, Bruno I just did the basic math in my head for the first time. So does that mean twin you guys are talking about a 15 to 16 degree bevel angle, that is the TOTAL included angle?

-

03-08-2015, 11:57 AM #4

Yes, that is correct. There is a variance of course. Not all razors are exactly the same in angle. But 15 to 16 seems right.

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

07-04-2015, 02:45 PM #5Senior Member

- Join Date

- Jul 2015

- Posts

- 143

Thanked: 9

We are talking about symmetrical grind here, arent we?

-

07-04-2015, 02:56 PM #6

Yes they are talking about western ground razors.

JonathanSHHHH!!!! It's "respect for the age of the blade", NOT laziness! - JimR

- JimR

-

07-04-2015, 09:48 PM #7

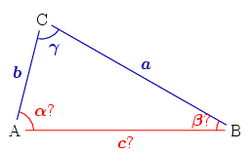

Here the example doesn't match our blade geometry but imagine an isosceles triangle with c? being the short side (spine) and gamma (

) our bevel angle.

) our bevel angle.

Two sides and the included angle given (SAS)

Here the lengths of sides a, b and the angle \gamma between these sides are known. The third side can be determined from the law of cosines:

c = \sqrt{a^2+b^2-2ab\cos\gamma}.

So for a 7/8" razor (.875") to get 16°

\sqrt{0.875^2+0.875^2-2x0.875x0.870xcos\16}

which is:

the square root of (blade hight² + blade hight² - 2 x blade hight x blade hight x the cos of the angle you want (16°)

equals 0.2435529268 or about 1/4"

Cut and paste from Google and calculated on my phone's scientific calculator; I could enter the whole equation in one line and get the answer.Than ≠ Then

Shave like a BOSS

-

07-04-2015, 10:24 PM #8Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,386

Thanked: 3228

While this talks about honing a wedge http://www.coticule.be/wedges.html the geometry applies to all grinds. There is an excel file download if you scroll down on the left. Just plug in your measurements to get your bevel angle. You can also see how the angle changes as you add a layer of tape.

BobLife is a terminal illness in the end

-

07-04-2015, 11:48 PM #9Saved,

to shave another day.

-

07-06-2015, 02:14 PM #10Senior Member

- Join Date

- Feb 2015

- Location

- Florida

- Posts

- 507

Thanked: 49

9Likes

9Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote