Results 1 to 8 of 8

Thread: First Finished Razor

-

08-29-2015, 11:19 PM #1Member

- Join Date

- Aug 2014

- Location

- Shippensburg, PA

- Posts

- 70

Thanked: 12 First Finished Razor

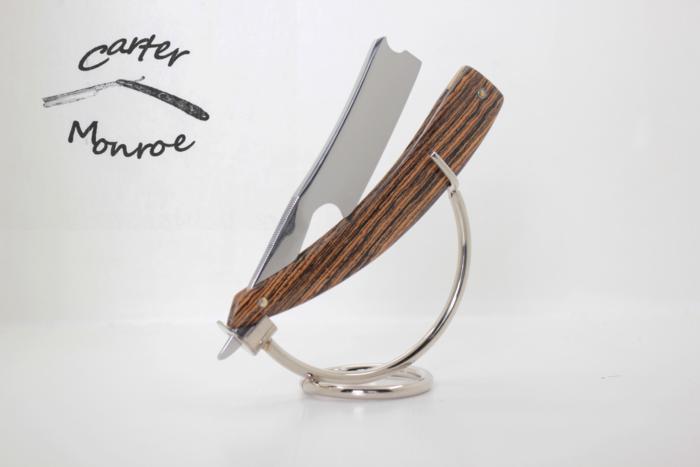

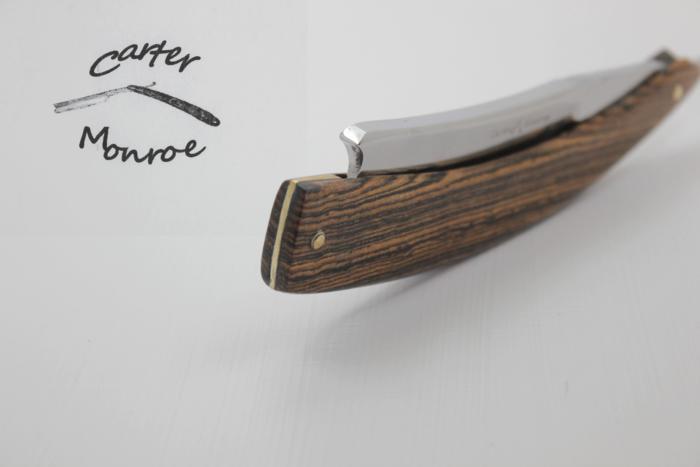

First Finished Razor

Okay so after much learning (reading, watching and doing) I have made a razor that really shaves nice, has a nice bevel and overall really it the best that I have done thus far. I must admit I have a small hand full of partially finished blades that well are not salvageable. This has been really a lot of fun learning and really I feel like I keep learning something new with every razor I try to make. This razor is made from O1 and really turned out nice. All in all I have about 3 days in it (not full working days just doing it as I have time) The scales are bocote wood and the wedge is solid brass. I would say for me the most challenging part of grinding is around the heel mainly because I try to makeeverything perfect and my pressure it not always consistent yet. I am open to any comments, thoughts, critiques, really anything I would love the input!

-

08-30-2015, 12:39 AM #2

Very Nice work mate, great job indeed

Is it forged or stock removal

Did you heat treat your self

What are the dimensions ?

It may be an illusion but the tail looks short or the thumb area on the tang is long ?

Most str8s I have measured ( my 80 odd) as a reference are 75mm - 3" blade, 40mm - 1.5" heal to pivot then 25mm - 1" plus for the tail from the pivot

Most measurements are +/- 5mm 1/4"

Just my observationsLast edited by Substance; 08-30-2015 at 12:42 AM.

Saved,

to shave another day.

-

The Following User Says Thank You to Substance For This Useful Post:

Jared13 (08-30-2015)

-

08-30-2015, 12:53 AM #3Member

- Join Date

- Aug 2014

- Location

- Shippensburg, PA

- Posts

- 70

Thanked: 12

Thanks for the compliment. It was mostly stock removal as my forging abilities are a work in progress. The only part that was forged a little was the tang. I did heat treat it myself . I normalized it twice , quenched it 3 times and did a tempered at 400 degrees. I made this out of an end piece of O1 that I didn't want to go to waste. It is a bit smaller that others that I have been making. The blade is just a hair over 2.5 inches and 13/16 wide. To be honest I would have to measure the heel to pivot and the tail to the pivot. I free hand most of the work I do and really don't plan much. It does have a smaller thumb notch which I thought might be an issue as far as ergonomics is concerned but it really feels nice in hand (at least in mine). Thanks for the input!

-

08-30-2015, 01:01 AM #4

Good looking blade, you are off to a great start.

Charlie

-

The Following User Says Thank You to spazola For This Useful Post:

Jared13 (08-30-2015)

-

08-30-2015, 01:12 AM #5Truth is weirder than any fiction..

- Join Date

- Jun 2012

- Location

- Land of the long white cloud

- Posts

- 2,946

Thanked: 580

Well if that is your first, very impressive.

Into this house we're born, into this world we're thrown ~ Jim Morrison

-

08-30-2015, 01:23 AM #6

I really like the notch at the heel end.

If I had to maybe criticise , I would say that a bit longer tail might be nicer.

That's what I don't like about T.I blades, their short tails.

-

The Following User Says Thank You to JOB15 For This Useful Post:

Jared13 (08-30-2015)

-

08-30-2015, 01:37 AM #7Member

- Join Date

- Aug 2014

- Location

- Shippensburg, PA

- Posts

- 70

Thanked: 12

I should clarify, this is the first razor that I would say turned out. I have about half a shoe box currently of duds that just didn't turn out for one reason or another

So this isn't my first attempt but this is the first one I would say I like as far as looks and function.

So this isn't my first attempt but this is the first one I would say I like as far as looks and function.

-

08-30-2015, 01:37 AM #8Member

- Join Date

- Aug 2014

- Location

- Shippensburg, PA

- Posts

- 70

Thanked: 12

Thank you that means a lot.

6Likes

6Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote