Results 1 to 10 of 17

Threaded View

-

11-03-2015, 12:59 AM #1

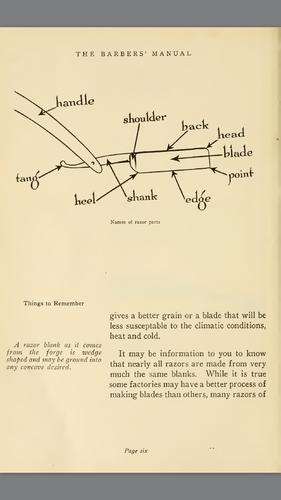

Razor Blanks made of welded steel wire?

Razor Blanks made of welded steel wire?

Forgive me if this question has been asked before. I was reading Mole's barbering manual and was intrigued by this passage on razor blanks. Are they still made this way ?

31Likes

31Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote