Results 51 to 60 of 65

Thread: O1 heat treating problem

Threaded View

-

11-17-2015, 10:51 PM #1

O1 heat treating problem

O1 heat treating problem

Hi Gents!

I'm in big trouble.

I made the following process:

normalizing: none.

soaking: ~805C/1480F, 15 min.

quenching oil: 50C, 30-40 sec.

tempering: after cool enough to touch, 205C/400F, 2x1h (between cooling to room temperature)

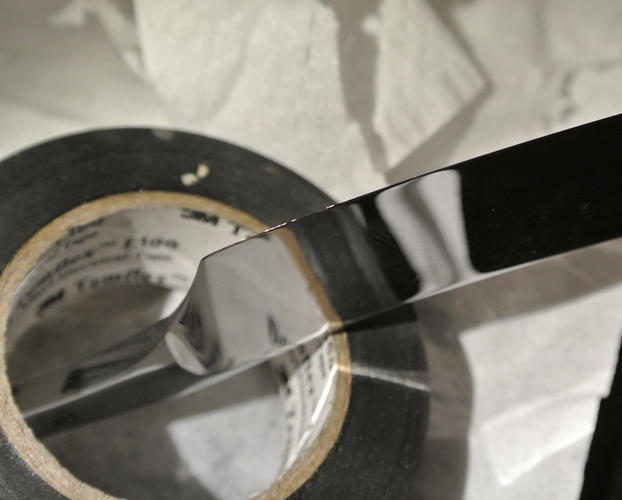

It seemed all right but I can't sharpen the blade. The edge is very sensitive (see the pic). What did I do wrong?

More picture from the heat treatment process (on the first pic: the first few minutes on 1480F):

Thank you in advance for your help!gregg

88Likes

88Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote