Results 11 to 20 of 36

-

11-23-2015, 03:34 PM #11

-

11-23-2015, 03:43 PM #12

I have done several razors now in Suminagashi and I heat up my medium speed quenching oil (same I use for 01) to 80c. No cracks, splits or anything. It has been flawless so far. This MO works great for me.

I tested quenching with A. a faster quenching oil (Parks 50) and B. with lower temps using both fast and medium oil (50C and 60C) and I got cracks towards the edge.

əˌfisyəˈnädō | pərˈfekSH(ə)nəst | eS'prəSSo | düvəl ləvər

-

-

11-23-2015, 04:15 PM #13

That settles it then. I probably quenched too cold. I'll have to buy a cheap fryer and mount it my quench tank

-

11-23-2015, 04:29 PM #14

-

11-23-2015, 04:48 PM #15

-

11-23-2015, 05:08 PM #16

I've been heating my oil in a double boiler set up and using a candy thermometer. The double boiler works well in that I can also easily cool the oil with a bath of cool water if I get it too warm.

-

11-30-2015, 11:51 PM #17

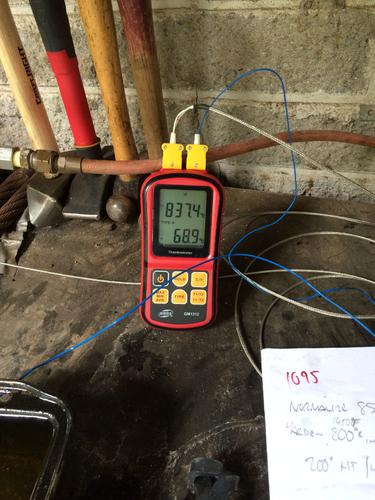

When Quenching I use a dual read out Thermo couple

1 in my forge & 1 in my oil

Saved,

Saved,

to shave another day.

-

The Following User Says Thank You to Substance For This Useful Post:

gregg71 (12-01-2015)

-

12-01-2015, 08:00 PM #18

Nice setup, thank you for sharing!

gregg

-

12-01-2015, 11:23 PM #19Senior Member

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1184

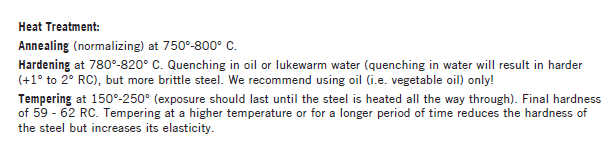

Okay so I went to customer service and got response next day :<0)

Thank you very much for your inquiry.

The item comes with instruction:

Best regards

Customer ServiceGood judgment comes from experience, and experience....well that comes from poor judgment.

-

12-11-2015, 11:49 PM #20

Update!

I maked a kamisori and everything was perfect. The grindig was difficult as Bruno said. I am pleased with the results. I got fine and sharp edge. Thank you for your help!

My process:

I leaved 1.5 mm thikness of the edge.

soaking: 805C / 1480F, 8 min.

quenching oil: 80C 20 sec - Thanks Maximilian

tempering: after cooling to room temperature, 210C 2x1h (between cooling to room temperature)

After this I sanded a few tenths of millimeters from the edge.

gregg

gregg

42Likes

42Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote