Results 1 to 10 of 12

-

05-18-2018, 11:48 PM #1Member

- Join Date

- Mar 2010

- Location

- Auckland New Zealand

- Posts

- 43

Thanked: 7 Will this Furnace work for Heat Treating Blades?

Will this Furnace work for Heat Treating Blades?

Hi Guys,

I'm located in New Zealand, so equipment is sometimes hard to source or carriage from overseas is prohibitive.

Up to now I have been outsourcing my heat treatment but would like to start doing my own.

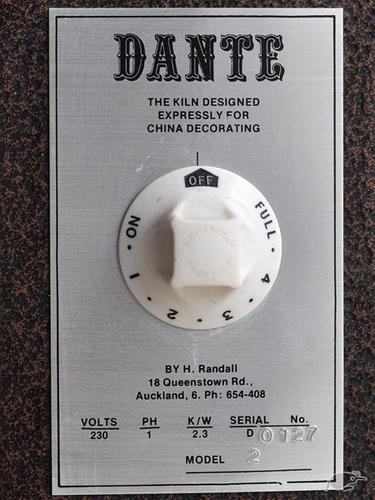

I've seen two similar heat treatment furnaces on our local NZ Trademe site. They are possibly more for Ceramics but from the description would you guys think either would work for hardening and tempering razor blades?

Here's the link for reference:

https://www.trademe.co.nz/Browse/Lis...?id=1633874558

https://www.trademe.co.nz/Browse/Lis...?id=1632573118

Both seem to heat to at least 1000 degrees Centigrade but don't have digital temp controls so I'd need another means of accurate temperature setting/monitoring?

Any advice appreciated.

DaveLast edited by onotoman; 05-19-2018 at 03:01 AM.

-

05-19-2018, 01:09 AM #2illegitimum non carborundum

- Join Date

- Jan 2008

- Location

- Rochester, MN

- Posts

- 11,552

- Blog Entries

- 1

Thanked: 3795

You need to be able to go a lot higher than 100 degrees. You need something that can do around 800 degrees.

-

The Following User Says Thank You to Utopian For This Useful Post:

spazola (05-19-2018)

-

05-19-2018, 02:24 AM #3

I think you meant 1000 degrees?

Is that Celsius or Fahrenheit?

If it's 1000C, then it might be OK, depending on what type of steel you're working with. For example the critical temp of O1 is somewhere around 800C. For A2 though, it is getting very close to 1000C. Other steels... I honestly don't know.

I'm far from a heat treating expert (that would be Mike Blue, btw), but I think I would be hesitant to reply on those. They'd have more than enough oomph for tempering though.

EDIT: Never mind what I said about A2. A2 crit temp is also around 800C. I should know better than trust my memory for such things...

Last edited by Cangooner; 05-19-2018 at 02:28 AM.

It was in original condition, faded red, well-worn, but nice.

This was and still is my favorite combination; beautiful, original, and worn.

-Neil Young

-

05-19-2018, 02:26 AM #4

I think it said 1000 C on the label. That would work for heat treat of carbon steels, that need in the 800-ish range.

Pid digital controllers are pretty cheap on Ebay, If you search for PID controllers you can find examples. A simple PID setup would control the furnace.

-

05-19-2018, 02:32 AM #5

when I bought my pid setup (ebay) it came in a kit that included the pid controller, thermocouple, solid state relay, and heatsink all in one package.

-

05-19-2018, 03:06 AM #6Member

- Join Date

- Mar 2010

- Location

- Auckland New Zealand

- Posts

- 43

Thanked: 7

Thanks guys,

Sorry, I meant to type 1000 degrees and it is indeed Centigrade, as used in UK (since 1972 ish) and New Zealand. I have edited the original post.

So both of these would seem to do the job with a PID controller/thermocouple setup added?

The older blue furnace/Kiln seems heavy at 62 KG, that's 136 lbs! The newer furnace/Kilns seem to be around 20 to 30 Kg, probably duw to modern insulation. Just thinking of carriage cost and lifting into my workshop and onto the bench.Last edited by onotoman; 05-19-2018 at 03:11 AM.

-

05-19-2018, 05:56 AM #7illegitimum non carborundum

- Join Date

- Jan 2008

- Location

- Rochester, MN

- Posts

- 11,552

- Blog Entries

- 1

Thanked: 3795

Sorry it never dawned on me that you left out a zero. I only took a cursory look at those ovens because I figured what's the point when they only go to 100? They did seem a little overbuilt for such a low temperature!

-

05-22-2018, 05:54 AM #8

Basically, any HT solution contains of 3 things: The control setup (PID + solid state relais + thermocouple), the heating coils, and the chamber.

The heating coils can be bought and hooked up the the relais, and the chamber is just refractory with good thermal insulation.

1000C is enough for carbon steels. The one thing I will add is that the heavier your kiln / oven is, the longer it will take to heat up, and the more electricity it will cost.Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

05-27-2018, 04:06 AM #9Member

- Join Date

- Mar 2010

- Location

- Auckland New Zealand

- Posts

- 43

Thanked: 7

Hi Guys,

Well, I picked up the Kiln/Furnace yesterday and it looks well looked after. The lady I bought if from threw in a crate of ceramic paints and brushes as well as some ceramic holders that go into the kiln to hold the work pieces.

With the furnace came a thermocouple (probe) and gauge that reads up to 1200 degrees Centigrade. The instructions for the turnace also state the max is 1200 C heats up within 1 hour.

This probe is poked down a hole in the top of the furnace to read the temperature.

My question is, should I buy a digital temperature control/PID/Thermocouple and would this be placed into the same hole used for the manual version? Would I also need some sort of adapter to fit a thermocouple snugly into the hole?

I would also presumably need to bypass the original control?

Many thanks

Dave

-

05-27-2018, 12:17 PM #10

It will work.

And it may be a good idea to buy a digital thermometer with a thermocouple, so that you can determine where the settings are for which temperature.

That would be simple enough.

Later you could -if you wish- take it apart and use a PID for controlling it digitally.

But yeah this oven will work. If you can buy if for a good price, do it.Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

21Likes

21Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote