Results 1 to 10 of 12

-

02-03-2019, 01:46 AM #1

Recommendations for a heat treat shop?

Recommendations for a heat treat shop?

I don't have my blanks cut yet due to a litany of things, but I should have them for real in the next week.

So!

Two questions.

What should my minimum thickness on pre-HT razors be? If my memory hasn't gone to hell, I recall Charlie grinding down to a little over 1mm. But I'm pretty sure he wasn't using 1084...

And I'm also going to need a recommendation for a shop that'll properly heat treat razors made from the stuff.

On a quasi-related note: I cannot find 1084 thicker than 1/4" (the steel I have was from Jantz, 1084 1/4"x4"x8.75")

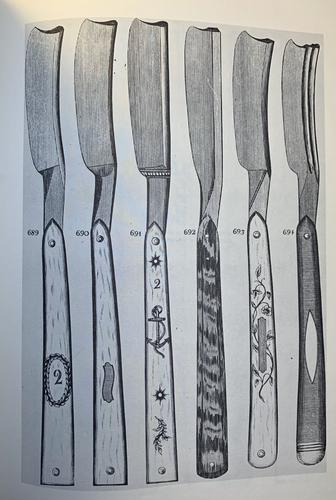

That's not going to be thick enough to make replicas of the largest old razors I have (my Magog razor is 11/32" thick at the thickest point, or 8.85mm). I don't have any plans to engage in the 'biggest razors' club thing, but there are a couple of old designs I wouldn't mind replicating that would require a thicker piece.

With the waterjet I have available, I could cut 3/4" or 1" 1080 bars down to size, but how is that for making razors?-Zak Jarvis. Writer. Artist. Bon vivant.

-

02-03-2019, 03:44 AM #2

-

02-03-2019, 06:22 AM #3

-

02-04-2019, 01:53 AM #4

I remember you posting about that one awhile back. The image with the hair follicle on the blade comes to mind. More of those blades in the world would not be a bad thing

-

02-04-2019, 03:04 AM #5Senior Member

- Join Date

- Feb 2016

- Location

- Pittsburgh, PA

- Posts

- 171

Thanked: 17

I just got 1084 from NJ Steel Baron, but the thickest he has is 1/4" as well.

-

02-04-2019, 04:13 AM #6

-

02-04-2019, 04:16 AM #7

-Zak Jarvis. Writer. Artist. Bon vivant.

-Zak Jarvis. Writer. Artist. Bon vivant.

-

02-04-2019, 06:23 PM #8

Most reputable shops should be able to noodle out a method for heat treating to a desired hardness. At worst case, they should be able to get it dialed-in in a couple cracks at it. I would recommend doing 4 or 5 test pieces of a rolls razor style. This way you can work with a specific company to find properties that you desire in your blades.

This type of back and forth is typically best handled in person with a local place. There was a place I was thinking of ordering from for one of my company's projects. They did custom blades for indistrial equipment and I think they were in your area. It'll take me a bit to find/remember their name...

-

The Following User Says Thank You to dinnermint For This Useful Post:

Voidmonster (02-04-2019)

-

02-04-2019, 07:13 PM #9

I have used Peter's heat treating a few times and have always been a happy customer.

https://www.petersheattreat.com/blades/

I think to get the thicker steel for stock removal you may have to find somebody with a press/hammer to dimension some stock for you.

If you are going to be farming out the heat treat, maybe look into other sorts of steels that would be the proper thickness.

I leave my edges a bit thick before heat treat, I like the safety margin. I shoot for something a nickel thickness or less, but not less than a dime. I just eyeball it.

1080, 1084, 1095,W2,W1 all are similar and will works as well as they are heat treated.Last edited by spazola; 02-04-2019 at 07:18 PM. Reason: link, more words

-

The Following User Says Thank You to spazola For This Useful Post:

Voidmonster (02-04-2019)

-

02-04-2019, 07:38 PM #10

Excellent!

Looking at Peter's Heat Treat, it would be in my best interest to do 15 at a time.

My short-term plan is to farm out heat treat -> sell razors -> buy kiln with proceeds, once I've got enough -> do it myself.

At the moment, I'm probably going to be grinding the first couple batches of razors using a drum sander on my drill press, but my first batch is going to be the old concaved or 'faux frameback' style that doesn't need a radius for the hollowing, so that shouldn't be *too* big a deal.-Zak Jarvis. Writer. Artist. Bon vivant.

-

The Following User Says Thank You to Voidmonster For This Useful Post:

spazola (02-04-2019)

17Likes

17Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote