Results 31 to 40 of 99

Thread: Gas forge for heat treating?

-

03-04-2019, 08:17 PM #31

You think it better to set it up same as your ht forge and just punch a hole in the back of the forge and line up a flared burner to shoot into that hole? Or can I just connect a burner with no flare to the back and still keep temps low enough to ht?

Awesome video of building a burner one of the better ones I’ve come across. Also have watched your video on recalescence. So the darker area is boundary between perlite and martensite?

-

03-05-2019, 12:21 AM #32

Pearlite and austenite. The transition from ferrite/pearlite to austenite is endothermic and the transition from austenite to ferrite/pearlite is exothermic. Pearlite is a layered structure of ferrite and cementite, hence the ferrite/pearlite. Martensite forms when austenite is cooled below the martensite start temperature ~425 F or so.

-

-

03-05-2019, 12:24 AM #33

I need to find that book you two showed me. Much to learn....

-

03-05-2019, 12:33 AM #34

-

03-05-2019, 11:57 AM #35

I found my materials science pre-engineering course at the U of Washington extremely difficult back in the day.

Thank FSM I have no good reason whatsoever to commit this esoteric, metallurgic information to my reachable, long term memory.

--Mark

--Mark

-

03-06-2019, 08:25 PM #36

-

The Following User Says Thank You to Bruno For This Useful Post:

jfk742 (03-07-2019)

-

03-07-2019, 01:11 AM #37

-

03-07-2019, 01:15 AM #38

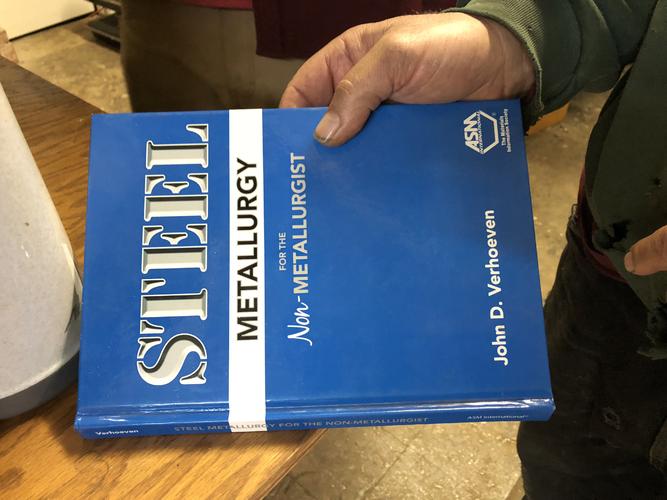

This is the book in case anyone was wondering (Charlie’s copy).

-

-

03-08-2019, 12:48 AM #39

I have a couple of 20lb propane tanks laying around, do you guys think the volume will be large enough assuming a muffler large enough for a chefs knife in diameter?

I’ve been looking at omega pyrometers and was thinking a 12” probe would work well, I’d drill a hole on the capped end of the muffler and insert it length ways from the back end of the forge, do you see any issues with that?

-

03-08-2019, 12:54 AM #40

Is there a place you guys like to order ceramic wool and bricks from? Thinking buying bulk as opposed to what I need right would save me some money in the long run.

I found some post anvil stock. After pricing out what a block of 4140 would cost I think I’m just going to pick up a 4x4x4 block already ht’d from old world anvils. Though I do have a scrap yard down the street from me, can I just walk around and hit things with a hammer and just grab whatever rings the best instead?

204Likes

204Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote