Results 1 to 10 of 63

Thread: 1095 stubby WIP

Hybrid View

-

01-13-2020, 01:40 AM #1

1095 stubby WIP

1095 stubby WIP

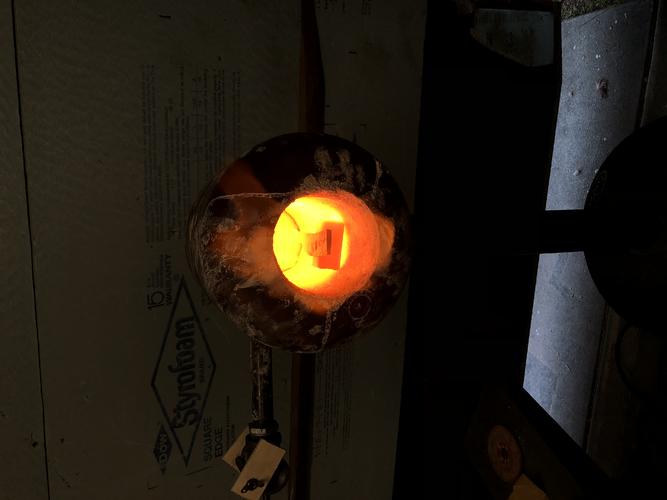

Just started this razor after getting a forge up and running. Going off of memory and what Iíve found on the internet as far as thermo-cycles and heat treat go. I banged out an rso on a railroad track section for an anvil. Looking to end up with one of these:

I normalized are what looked like bright cherry, then cycled down from there until I hit an even dull red, maybe 4-5 cycles. I also turned down the forge progressively. On the last heat I shut the forge off and let the razor go to black on the anvil then stuck the steel back in and capped the ends of the forge to let it all cool slowly and hopefully anneal the steel for grinding and filing.

Hoping for any input or suggestions on how to end up with a decent heat treat and fine grain structure. I do have another gas forge I made for heat treating. It has a muffler and a thermocoupler for monitoring the temp. I do plan after rough grinding to go through a proper normalizing and grain refining session. I definitely would like to learn my colors. For tempering I started on a pid controlled deep fryer that I still need to get some low temp salts for. Plannng on 2-3 tempering cycles at 400f.

Again, this is my plan based on a dangerously small amount of experience and reading. An and all help would be appreciated.

-

01-13-2020, 12:10 PM #2Senior Member

- Join Date

- Dec 2012

- Location

- Egham, a little town just outside London.

- Posts

- 3,857

- Blog Entries

- 2

Thanked: 1083

Cant help whatsoever but good on ya for having a go and good luck

-

01-13-2020, 02:49 PM #3

First of all I have to say you have an amazing aptitude for grinding razors, your hand eye coordination is next level.

Everything you mentioned in heat treat process sounds good. Using the muffler and waiting to see decalescence happen then, hold it for a little bit, then quenching sounds like a plan. Two tempering cycles is good.

If you have some scrap you can practice your process, then break it to see what the grain looks like.

-

The Following User Says Thank You to spazola For This Useful Post:

jfk742 (01-13-2020)

-

01-13-2020, 04:56 PM #4

Keep in mind that 1095 has a low hardenability, so any test pieces should be at about the same thickness as the thin part of your razor in order to cool fast enough.

-

The Following User Says Thank You to bluesman7 For This Useful Post:

jfk742 (01-13-2020)

-

01-13-2020, 05:51 PM #5

So if I end up at say .030” at the edge that should also be the thickness of my test sample? I have #50 quench oil. Is 120f preheat for oil a good temp to start at?

-

01-13-2020, 08:10 PM #6

I'd guess up to .08" or so would be thin enough, but I would also think that it would be easy enough to match the razor thickness pretty close.

I like to go up to ~ 150ļF with my quench oil, but I usually use canola, so it might be different for #50.Last edited by bluesman7; 01-13-2020 at 08:21 PM.

161Likes

161Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote