Results 1 to 10 of 19

Threaded View

-

01-27-2020, 02:47 AM #5

IT’S ALIVE!

Well, mostly alive. I could grind on it now if I wanted to, but for a variety of reasons I don’t want to yet.

Most importantly, the motor really needs a functional fan and ventilation system. The DC treadmill motor I’m using is fully open frame and was used in the treadmill with an integral fan blade to force air through the fan.

That will kill the motor dead as a grinder, and probably a lot sooner than later.

I have a plan of attack!

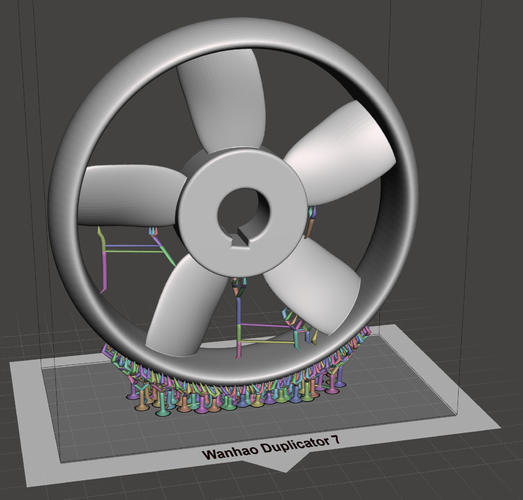

The original fan blade was integrated into a 5-10lbs flywheel, which I absolutely do not need. I already designed and printed a replacement.

Unfortunately, I was in a hurry to get it to my friend so he could start it printing and I could pick it up the next morning. It blows air the wrong direction (and kinda poorly at that). So I need to redesign the fan.

The motor has arbors sticking out of both ends (it’d make a great buffer — it’s only about 4.5 inches in diameter), the fan goes on one end and the drive wheel on the other. When it’s operating correctly, the fan pushes air through the frame of the motor.

What I plan to do is build a sheet metal shroud that’s air-tight. On the vent end, I’ll extend the shroud and stick the motor controller (since it needs air cooling as well), so that all the air forced through the motor then goes through the motor controller.

I’ll stick a short length of duct onto the intake, attach a dowel or something to the bench, and have the air intake up near the ceiling (with a filter on it), the idea being that the metal dust shouldn’t be going up nearly as much as it goes down. I’ve also got a couple of ideas for controlling the dust. It’ll include the usual bucket of water just below the grinder wheel as well as a couple of plates or something to deflect the most wayward sparks.

All that should keep the motor in its happy place.

The controller is an SCR voltage regulator running through a bridge rectifier.

I’ve gone over and over this part because it looks like the SCR/bridge method is not the greatest. I would normally have just scrounged the controller out of the treadmill I took it from since it was fully functional, but it’s an old model and it’s super picky and insists that it has everything else connected or it just won’t run. So if the incline motor and it’s sensor aren’t there, it won’t even power on. If the speed sensor isn’t there, it’ll spin up briefly then shut down and beep loudly. Also it’s parts are spread over two PCBs that are both nearly 3 feet wide, and all the controls are on a floppy membrane panel.

TL;DR — original controls non-viable.

Other tweaks:

The motor seems to really want to be raised up about 4 inches from where it’s at.

It’s currently mounted to a cheapo Harbor Freight workstand. It really doesn’t feel as secure as I’d like, however, and I’ll probably get a better stand later.

Other thoughts.

I’m really happy with the build quality on the OBM grinder. It’s a sturdy chunk of kit.

I opted for 1 each of:

VSM 36 grit ceramic

VSM 60 grit ceramic

VSM 120 grit ceramic

A160 (120 grit) Trizact

A65 (280 grit) Trizact

A30 (600 grit) Trizact

VSM cork

Gonna see how I feel about those before getting any kind of quantity.-Zak Jarvis. Writer. Artist. Bon vivant.

50Likes

50Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote