Results 1 to 10 of 20

Thread: Coil Spring Razor

-

06-16-2020, 02:10 PM #1Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59 Coil Spring Razor

Coil Spring Razor

Elsewhere we were talking about using automotive springs for razors. During that conversation the topic of coil springs came up, so I thought that I would share how I build a razor out of a coil spring. This is off of a 3/4 ton Dodge Ram, so it is pretty thick. (My buddy installed a lift kit in his truck and gave me the old springs) My biggest goal here is to show you how much steel it takes to make a razor. Now I could of gotten more width out of this piece if I had decided to forge more of the edge bevel, instead of grinding so much of it out. As it is, I simply forded it flat and to the correct profile. From there I ground it.

The pictures with the anvil are before it ever saw a grinder. It ended up being 0.35" after forging and over an inch wide. You can see that going from forged to rough ground, it lost a fair amount of thickness and is currently at 0.315". I still have more polishing to do as well. If people find this useful, I show how I do it on a leaf spring as well, so you can see how I thicken them up.

-

-

06-16-2020, 02:32 PM #2

That is very cool. My ambition (if I ever get enough time away from the business and don't die at 95 sitting at my workbench) is to get a forge and make some razors. My dad had an old forge shaped like a round BBQ grill on a.stand with the hand crank bellows blower underneath. He had the farrier's anvil with the square hole and the matching chisels, the hammers, ladels and tongs. He had molds for round musket balls and 58.6 caliber miniballs. I wish I still had all that stuff.

Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

06-16-2020, 03:06 PM #3

Thanks for this. I guess the same caveat applies to making knives from springs: if you forge with used springs, they *may* have hairline cracks that only show up after putting a bunch of work into it.

I've used both coil and leaf springs for making knives and they work great. I have absolutely no idea why I didn't think of using that material for a razor: thanks for the nudge.

It was in original condition, faded red, well-worn, but nice.

This was and still is my favorite combination; beautiful, original, and worn.

-Neil Young

-

06-16-2020, 10:13 PM #4

Did you forge that in your coal forge? I would be interested in seeing a leaf spring project also. That would make for a good YouTube video...nudge, nudge.

Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

06-16-2020, 10:46 PM #5Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

Yes, that was in my coal forge. I’m starting to get the hang of the new forge now. Thursday I have two young kids (10 - 13 years old) coming over for a forging lesson, so I wanted to get some more of the bugs worked out first.

I have a piece of leaf spring picked out and marked for a razor, so I’ll at least photograph that for you.

I need to make some paying projects though to pay for grinding belts and coal.

-

06-16-2020, 11:00 PM #6Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

You are very welcome. Cracks are a risk, but this particular piece was from a “mall crawler” truck (all show and only a few easy miles). The springs were like new. I have seen cracks in old leaf springs though.

Personally I think old automotive springs make better razors than they do knives.

-

06-17-2020, 04:00 AM #7

That's an awesome thing for a kid to be able to do. I would dig that myself. There is a place you can take forging lessons here in my neck of the woods. My nephew did it and they make a blacksmith knife out of the deal. The guy is a great big Scot who wears a leather kilt so it adds to the atmosphere. Funny I was apprenticed 40 years ago...

...longer actually...in my trade and I have apprenticed my son and a few others for the family business. It would be kind of interesting at my age to apprentice again in blacksmithing. Then I could be 2 different kinds of smiths.

Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

...longer actually...in my trade and I have apprenticed my son and a few others for the family business. It would be kind of interesting at my age to apprentice again in blacksmithing. Then I could be 2 different kinds of smiths.

Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

06-18-2020, 03:38 AM #8Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

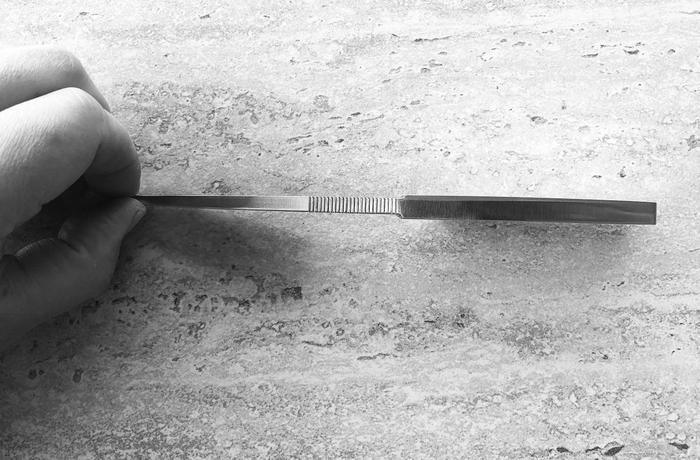

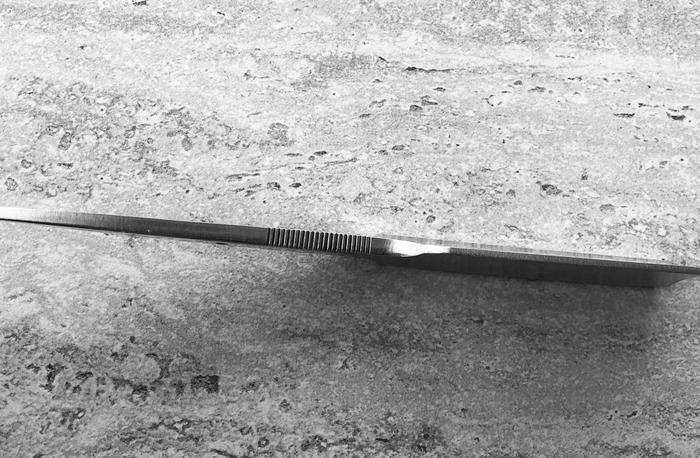

Ready for heat treating. The tail is pretty much done, but the edge is still thick (to help combat warpage during quench). I was having troubles with the lighting and getting it to show the spine thickness and the jimping, so I made them black and white to help show the outline. This one will head off to Glen when it is done (assuming I don't botch it in the mean time) for evaluation and feedback.

-

The Following User Says Thank You to DVW For This Useful Post:

PaulFLUS (06-18-2020)

-

06-18-2020, 03:43 AM #9

Those jimps look really precise. Did you do that by hand?

Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

06-18-2020, 03:50 AM #10Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

76Likes

76Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote