Results 1 to 10 of 15

Thread: Old Razor Repro

Hybrid View

-

11-17-2020, 09:02 PM #1Senior Member

- Join Date

- Jul 2020

- Posts

- 270

Thanked: 44 Old Razor Repro

Old Razor Repro

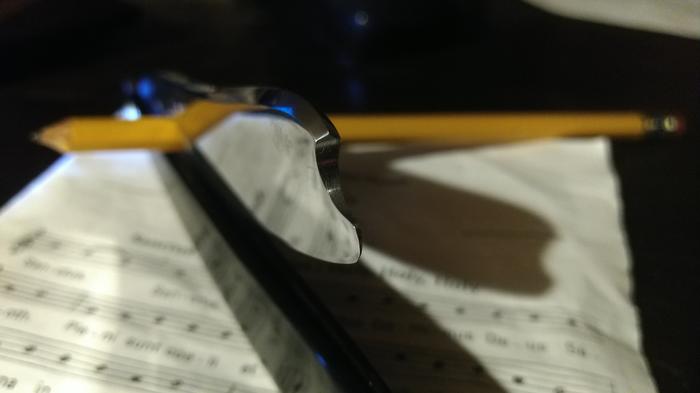

Just completed this Sheffield style razor this morning, a little personal project. 52100 steel, black acrylic scales, lead wedge, bullseye washers.

-

-

11-17-2020, 09:29 PM #2Senior Member

- Join Date

- Sep 2020

- Location

- Austin, TX

- Posts

- 653

Thanked: 56

Looks great.

If you're wondering I'm probably being sarcastic.

-

11-17-2020, 09:38 PM #3

Nice work. As far as I can tell the scales look stuffed with blade.

It's just Sharpening, right?

Jerry...

-

11-18-2020, 02:45 AM #4

Can you show a pic of the grind shape? What size wheels did you use?

-

11-18-2020, 04:18 AM #5Senior Member

- Join Date

- Jul 2020

- Posts

- 270

Thanked: 44

Hope these pics are ok, if not I can take some better ones in the morning. The faces of the blade were ground on a 10 inch contact wheel, but I rocked the blade as I was grinding to create an even larger radius so it's probably closer to something like a 12 inch. The spine is chamfered, the two chamfers come together at the toe and diverge as you go toward the tail; this leaves a flat area for the fingers to grip instead of resting on a peak.

-

-

11-18-2020, 07:32 PM #6Senior Member

- Join Date

- Jul 2020

- Posts

- 270

Thanked: 44

Got a few more of these on the go, finished the grinding today. After hardening all rough work starts out on a 60 grit ceramic belt. Then I progress going over each surface through 120 grit ceramic, 220 ceramic, 400 SiC, 600 Sic, finally ending with a Trizact A16 grade belt which is the equivalent of 1200 grit. This gives a nice glaze type finish, partially reflective with very fine scratches that appear iridescent when viewed through a loupe. On some of the belts I will use a grease to just fine the cut a little and provide cooling and lubrication.

53Likes

53Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote