Results 1 to 10 of 16

Thread: Help 8/8

-

07-30-2009, 06:49 PM #1

Help 8/8

Help 8/8

Hello!

I bought a bar of steel 52100, and I want a razor blade 8/8, but I never saw one, could someone pass me measures of a razor 8/8.

I want know the length, thickness.

The steel is 37mm x 8mm x 250mm .

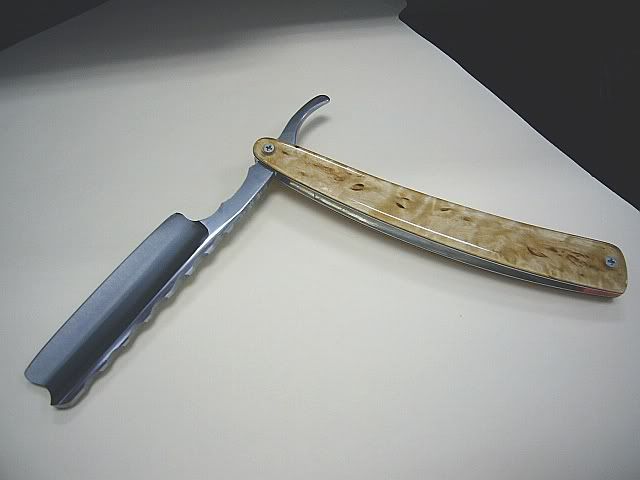

I would look like these models.

Gostaria de qualquer um destes.

Thanks

Ale

-

08-01-2009, 12:43 AM #2Professional Pedantic Pontificator

- Join Date

- Apr 2009

- Location

- Monmouth, OR - USA

- Posts

- 1,163

Thanked: 317

What measurements do you need specifically?

I don't have any 8/8, but I do have a good shaving 7/8 and I could easily extrapolate the numbers you'd need for an 8/8.

-

08-03-2009, 09:00 PM #3

If you are ordering a custom cutlery service and need to instruct someone on how the geometry of a blade should be, I don´t think the result would be of any good.

If you want to make one yourself, I suggest you to shave more. To understand why razor blades are the way they are. Cuting angles, honing, durability, etc. Of course, then read about bladesmith.

Best,

Felipe

-

08-03-2009, 10:54 PM #4

That advice is golden. Really- if you need to ask about the geometry of an 8/8 blade then you aren't ready to make one. You need to get your hands on more razors and really study them yourself. This is a huge reason many knifemakers can't and won't make razors- because they don't have enough experience with them themselves.

-

08-05-2009, 03:49 PM #5

While the above two are absolutely correct, IMHO, I could send you the dimensions of an excellent shaving 1/2 hollow 8/8 and an equally excellent full hollow 8/8. It would probably have to wait until tomorrow night, as I am busy today and tonight. If I can find my digital calipers, the measurements might even be accurate!

-

08-05-2009, 04:25 PM #6

I agree as far as making a blade using dimensions as reference, I wonder though.....

if a person was setup correctly for going from a pattern, and had an excellent blade to pattern from, couldn't they duplicate it? for instance I think most of the guys grinding blades grind them by hand right, which does take more skill, understanding etc. but what if a person was using a grinder that was capable of very precise grinding, dialed in, not dependent on the operator so much? Just curious.

Red

-

08-05-2009, 08:04 PM #7< Banned User >

- Join Date

- Feb 2008

- Posts

- 3,763

Thanked: 735

All I can say is that guy has good taste in razors!

-

08-06-2009, 02:04 AM #8

Lol, well it is. Many knifemakers won't even try it. There's a reason why some customs look a lot sloppier than others- cause it ain't easy to do WELL.

Red- you mean like using a CNC machine to grind the shape? That could work. But again- you'd probably want a $20,000 CNC machine first lol.

-

08-06-2009, 11:06 AM #9

I bet using a CNC setup to make razors would be nerve wracking.

Taking something that thin and flexible and putting it in a jig or magnetic chuck consistently would be a nightmare if you were looking to keep the tolerances tight.

Doing finish work, without doing it by hand is really, really hard IMHO.

I have flung a few thin little sheets of steel off the grinder working on small pieces like that, and using a mill wouldn't be much easier, I bet.

Now, a plunge EDM would open up some interesting blade geometry possibilities...

-

08-06-2009, 08:15 PM #10

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote