Results 1 to 10 of 15

-

12-25-2009, 04:51 AM #1

Water vs Steel: Holiday Fun with sweet tools

Water vs Steel: Holiday Fun with sweet tools

Hey guys, I took my little family across the nation to spend Christmas in my childhood home in Oregon. It's always nice to see the parents and watch them enjoy their grandson, but it's also lots of fun to get a week or two to do some projects with my Dad.

See, my dad is a guy that built a business from the ground up building industrial controllers for things like road striping trucks, pavement grinders, asphalt spreaders (big machines with kind of high tech electronic controllers). In his line of work, it has been necessary for him to have some very cool machines in his shop. I am starting to realize how fortunate I was to have access to his machines from time to time.

Without further ado I'd like to introduce everyone to the sweet little machine my dad and I spent part of the afternoon with: The WaterJet Cutting Table.

This machine uses water under extremely high pressure (42,000 psi !!!) and garnet to cut just about material you could think of according to a CAD type drawing. Oh yeah, it also cuts with a kerf of under 14 thousandths of an inch.

So naturally I mocked up a razor design, got a piece of 1080 carbon steel and decided to make a day of it.

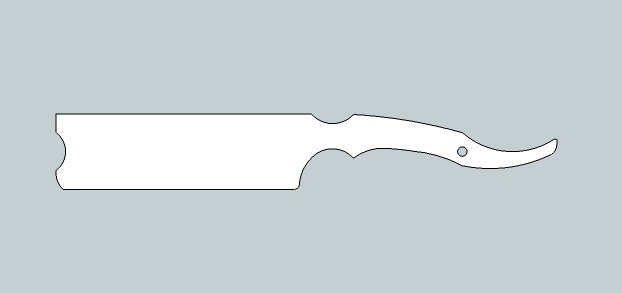

Here is the design I made

It will end up in an 8/8 razor with about a 1/4 grind. I based this design on a few of my favorite old brands, as well as some of the things you crazy cats are doing out there with your shapes

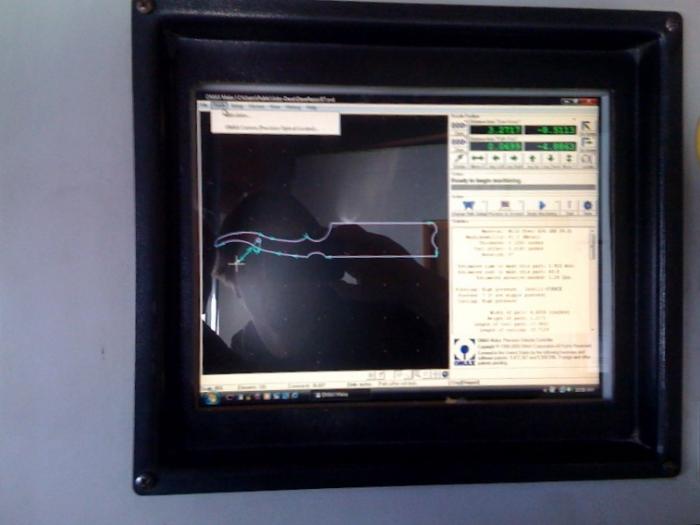

Here it is on the WaterJet screen

Yeah, you can kinda see me in the reflection. I had a stocking hat on before I got there and you can see my hat-hair in the screen...oh well

The waterJet nozzle works under water, so you actually submerge the stock. Here you can see a sheet of mild steel with a razor shaped hole in it. I did this as a test run before hitting the 1080 with the jet. This razor took about 45 seconds or so to cut out.

Here is the blank that came from that cut

After that, I set up my piece of 1080 and went to town. Here you only see two blanks, but I actually got three blanks out of my piece of steel (I only lost about 1/2 inch total out of the bar to waste).

Over the next few days I'll be grinding the blades to shape, so I'll keep you posted. This day of cutting actually leads into our project for the next week and a half when we build my computer controlled heat treating furnace that will be capable of heating to temps of up to 2300 degrees F... that should be plenty. So if anything goes according to plan I should have a few homebrew razors before too long.

Anyway, I hope you enjoyed the post. Thanks for letting me use your machine pops!

-

The Following 3 Users Say Thank You to Del1r1um For This Useful Post:

hi_bud_gl (12-31-2009), ScottGoodman (01-30-2010), Stubear (01-05-2010)

-

12-25-2009, 04:58 AM #2lost

- Join Date

- Jan 2008

- Posts

- 3,446

Thanked: 416

Dude you have no idea how cool that is!!!!!

-

The Following User Says Thank You to Doc For This Useful Post:

Del1r1um (01-05-2010)

-

12-25-2009, 05:56 AM #3

Dude, you have no idea how lucky you are.

Keep posting.

-

The Following User Says Thank You to smythe For This Useful Post:

Del1r1um (01-05-2010)

-

12-31-2009, 04:23 AM #4Senior Member

- Join Date

- Oct 2008

- Location

- Munford TN

- Posts

- 436

Thanked: 46

Dude, you have no idea how much we hate you lol. please keep us posted. this is to neat to miss

-

The Following User Says Thank You to jballs918 For This Useful Post:

Del1r1um (01-05-2010)

-

12-31-2009, 04:30 AM #5Senior Member

- Join Date

- Apr 2009

- Location

- Fayetteville, GA

- Posts

- 227

Thanked: 20

Dude....

-

The Following User Says Thank You to MinniesMate For This Useful Post:

Del1r1um (01-05-2010)

-

12-31-2009, 04:30 AM #6

Dude, you have no idea how much I wanted to post something starting with "Dude, you have no idea"!

That is seriously cool. I really like the design, and I wish you the best of luck with your homebrew project.

-

The Following User Says Thank You to holli4pirating For This Useful Post:

Del1r1um (01-05-2010)

-

12-31-2009, 04:31 AM #7

-

The Following User Says Thank You to hi_bud_gl For This Useful Post:

Del1r1um (01-05-2010)

-

12-31-2009, 04:33 AM #8

I wanna go to YOUR house for Christmas next year....WOW!!

-

The Following User Says Thank You to BKratchmer For This Useful Post:

Del1r1um (01-05-2010)

-

12-31-2009, 04:34 AM #9---

- Join Date

- Jan 2009

- Posts

- 1,230

Thanked: 278

Dude... What they said!!!

-

The Following User Says Thank You to Rajagra For This Useful Post:

Del1r1um (01-05-2010)

-

01-05-2010, 07:12 AM #10

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote