Results 11 to 18 of 18

Thread: Hobby-level forging

-

03-02-2010, 11:24 PM #11

"Blues fallin' down like hail." Robert Johnson

"Blues fallin' down like hail." Robert Johnson

"Aw, Pretty Boy, can't you show me nuthin but surrender?" Patti Smith

-

03-02-2010, 11:51 PM #12Senior Member

- Join Date

- Aug 2009

- Posts

- 186

Thanked: 20

Awesome! Did you get the wheels from Beaumont? I'm thinking of keeping the costs down and buying them from Sunray. I hear you on the vfd... definitely nice but the costs then become exponential. Just scored a nice Leeson 1.5HP for 30$ so that'll have to do! Plus... like some tools, they're nice to have but not necessary.

(Keep on thinking that! haha)

(Keep on thinking that! haha)

Also.. would you *ahem* be interested in *ahem* making another one?

Last edited by v76; 03-02-2010 at 11:55 PM.

-

03-10-2010, 10:49 AM #13

-

03-11-2010, 11:02 PM #14Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

I believe that ChrisL purchased his wheels from Sunray. The problem is "slop" in the ID of the wheel bearings/axel fit that results in vibration of the contact wheel. The slop has to be taken out by use of a "shim" or a custom machined bolt/axel. There are a number of "gotchas" when you build your own grinder. I helped chris when he built his. I have built 4 of them.

Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

03-11-2010, 11:10 PM #15

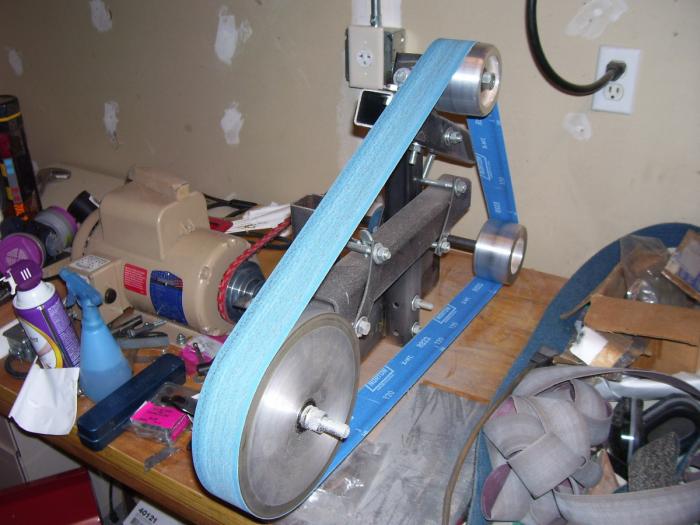

Oops, sorry, I hadn't been back to this thread in awhile. Yes I bought my wheels from Sunray and they were great to deal with. The largest I have is 8" at this point. I think my wheels run quite true; any "hop" is for all practical purposes minimal to imperceptible.

Building one was enough for me. I actually want to upgrade mine a bit by redrilling some of the holes with a mill rather than a drill press, fly cutting a flat surface of the main tube to mount the pillow blocks, etc.

The main costs are the wheels and the motor with the steel, fasteners, pulleys, pillow block bearings running a close second. Great deals on motors of course bring the cost down. Randy has worked on some homemade contact wheels and if you twist his arm, he may expound on that.

Chris L"Blues fallin' down like hail." Robert Johnson

"Aw, Pretty Boy, can't you show me nuthin but surrender?" Patti Smith

-

03-11-2010, 11:49 PM #16on quest for the better shave

- Join Date

- Aug 2009

- Location

- MD

- Posts

- 57

Thanked: 6

Randy expound expound... Homemade contact wheels how?

-

03-12-2010, 12:08 AM #17Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

I will post a thread with pics in a week or two. Trying to describe it in just words would take to long. Essentially it is layers of MDF board glued together then turned down to size and covered with a 50 durometer rubber. The main point is a custom made/ machined wheel bearing assembly. That should result in a very smooth turning of the contact wheel. A smooth running contact wheel is a necessity for repetitive work.

Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

03-12-2010, 12:38 AM #18

Smelting is way hard. You need iron ore and HARD to find

good iron ore at that. No impurities... just carbon in controlled amounts.

Shaping and heat treating is another thing all together.

A small propane furnace can heat it...

You can start with steel from an old file....

Heat it so you can work it with a hammer on

an anvil (18" of train rail will do) into a rough shape.

Drill the tang hole

Hammer or rough grind it to an approximation.

Harden and anneal then finish grind

and finish polish on a wet slow spinning grinder ....

Add scales and hone to perfection....

Sounds oh so easy....

Start with some ugly E-bray rusted to heck

prizes and work the process backward. No point

in working a good blank of steel for a week only to

wreck it on the buffer in ten seconds.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

I should be ready to forge in the next 2 weeks or so! I'm still scavenging parts to make an EERF KMG grinder clone and then I should be set, tools-wise for a good while!

I should be ready to forge in the next 2 weeks or so! I'm still scavenging parts to make an EERF KMG grinder clone and then I should be set, tools-wise for a good while!

Reply With Quote

Reply With Quote