Results 31 to 40 of 58

Threaded View

-

02-26-2010, 01:33 AM #1aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936 Scott's trying to make a razor???

Scott's trying to make a razor???

Ok, so I begged and pleaded with Dave (Del1r1um) to let me in on the blanks he was going to do with a waterjet. I expected that he would have put up a bigger fight, but he's a nice guy and simply said "OK". I'm still not sure if I bit off more than I could chew, but below is a chronology of my making my own straight razor. I plan to do it all but the tempering/heat-treating...I'm still too much a rooky to try and mess with a forge...SO, WOULD SOMEONE VOLUNTEER YOUR SERVICES VIA PM, willing to pay for your services.

First I changed the profile a little...

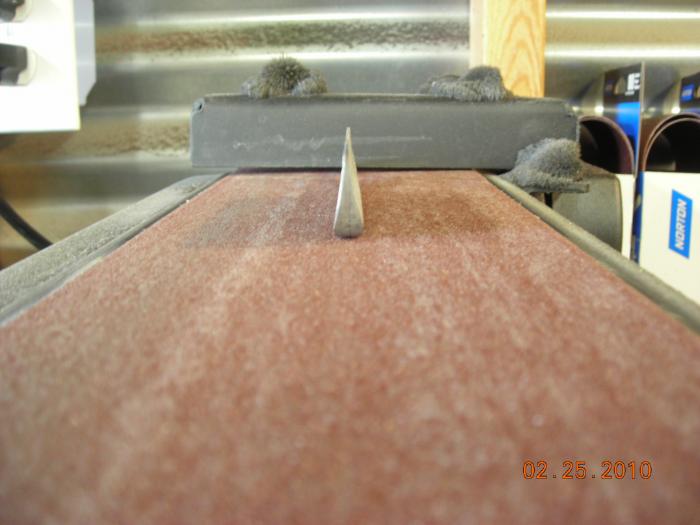

Started out grinding it as a true wedge...

MMMM..... Thought about those Japanese straights for a bit...

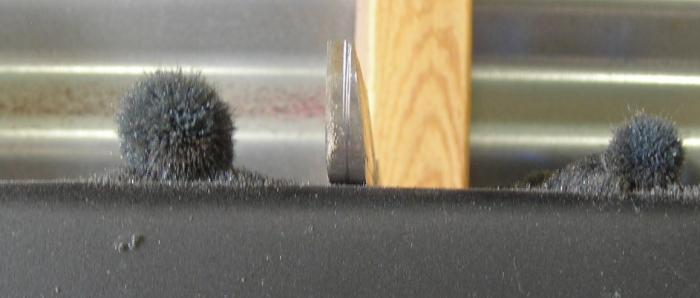

It's tough getting the grinding even, the 4x36 belt also removes skin...

Notice the scribe marks for center, used a sharpened center punch...

Southern ingenuity at it's best!!!

About as far as I want to take it before temper/heat-treat...

Rough hollow...

After a little more profiling...

Different angle, ready for some heat...

OK, so now you have it, where have I messed up? The edge is currently .03-.035" at it's thinnest point (shaving edge). Spine width is .25". I didn't get too carried away with cleaning up the grind marks and all since it will need a bit of cleanup after it's been in the forge.

Any and all comments are welcomed and more than likely needed...

Thanks again Dave, I probably wouldn't have ever attempted this without your generosity.Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

84Likes

84Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote