Results 1 to 10 of 58

-

02-26-2010, 02:33 AM #1aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936 Scott's trying to make a razor???

Scott's trying to make a razor???

Ok, so I begged and pleaded with Dave (Del1r1um) to let me in on the blanks he was going to do with a waterjet. I expected that he would have put up a bigger fight, but he's a nice guy and simply said "OK". I'm still not sure if I bit off more than I could chew, but below is a chronology of my making my own straight razor. I plan to do it all but the tempering/heat-treating...I'm still too much a rooky to try and mess with a forge...SO, WOULD SOMEONE VOLUNTEER YOUR SERVICES VIA PM, willing to pay for your services.

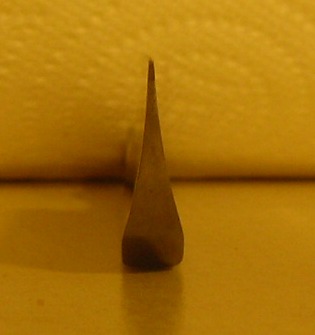

First I changed the profile a little...

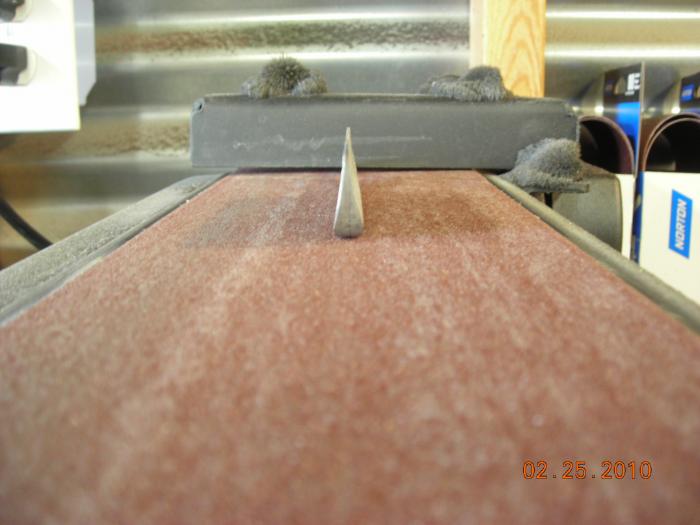

Started out grinding it as a true wedge...

MMMM..... Thought about those Japanese straights for a bit...

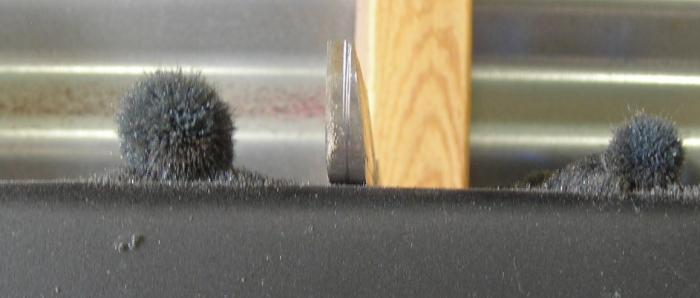

It's tough getting the grinding even, the 4x36 belt also removes skin...

Notice the scribe marks for center, used a sharpened center punch...

Southern ingenuity at it's best!!!

About as far as I want to take it before temper/heat-treat...

Rough hollow...

After a little more profiling...

Different angle, ready for some heat...

OK, so now you have it, where have I messed up? The edge is currently .03-.035" at it's thinnest point (shaving edge). Spine width is .25". I didn't get too carried away with cleaning up the grind marks and all since it will need a bit of cleanup after it's been in the forge.

Any and all comments are welcomed and more than likely needed...

Thanks again Dave, I probably wouldn't have ever attempted this without your generosity.Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

-

02-26-2010, 02:56 AM #2aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

Didn't put a pic of the 1/4 hollow...

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

02-26-2010, 03:15 AM #3"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

That didn't turn out too bad. I think where you stopped grinding is just about right. What steel is it?

“Nothing discloses real character like the use of power. Most people can bear adversity. But if you wish to know what a man really is, give him power.” R.G.Ingersoll

-

The Following User Says Thank You to Mike Blue For This Useful Post:

ScottGoodman (03-02-2010)

-

02-26-2010, 03:28 AM #4aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

1095 if I remember correctly, have to double check...

Last edited by ScottGoodman; 02-26-2010 at 03:32 AM.

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

02-26-2010, 03:30 AM #5

Looks great man. I'm waiting for a few things to arrive before I start working on mine.

-

The Following User Says Thank You to Muirtach For This Useful Post:

ScottGoodman (03-02-2010)

-

02-26-2010, 07:45 AM #6aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

Double checked, it's 1095.

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

03-01-2010, 08:24 PM #7

Looking good, do you plan to heat treat yourself?

Never thought of using a bench sander to do hollowing, giving me ideas.

Might practice on some scraps to develop technique.

Which direction is belt moving, away or toward edge?

-

The Following User Says Thank You to Deckard For This Useful Post:

ScottGoodman (03-02-2010)

-

03-02-2010, 02:38 PM #8aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

Sent it off to Butch yesterday to have treated, give me a little while though... Belt moves away from me if you are looking at the pic above. I'm still scratching my head on the smiling blank on how to go about hollowing it out. "Necesity is the mother of all invention", I just use what I have...which isn't much compared to some of these guys shops.

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

03-02-2010, 02:55 PM #9Senior Member

- Join Date

- Jan 2008

- Posts

- 701

Thanked: 182

there are 2 ways to follow the smile

one is rotating the blade and the other is to tip the heel and toe "into " the grinder (rocking the grind)

i ll haveot get pics or vid to help as its alot easer then it sounds

i use both ways to keep things even and also i have found that jsut following the spine around the grind itsself i over thin the belly

-

The Following 2 Users Say Thank You to L R Harner For This Useful Post:

Del1r1um (03-10-2010), ScottGoodman (03-02-2010)

-

03-02-2010, 04:02 PM #10aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

I can mentally picture what you are talking about, but for the smiling blank I would think that the 4" wide belt is just too wide for rocking left to right. Is my thinking right?

I used a rocking motion for this razor, rocking from spine to edge on the cinderblock pictured in the OP.Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

84Likes

84Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote