Results 11 to 20 of 26

Thread: F. Herder blanks

-

09-05-2010, 05:04 PM #11

ktinch, let us know what happens, thanks!

It is easier to fool people than to convince them they have been fooled. Twain

-

09-09-2010, 04:43 PM #12

I also ordered two batches and would like to have access to your findings about the correct hardening and tempering of these blades.Thanks!

~RichardBe yourself; everyone else is already taken.

- Oscar Wilde

-

09-10-2010, 07:16 AM #13Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

I had some of these before. The hardness was tested at Mike Blues and came in at 58 HRC. So they were heat treated and tempered. At least mine were. The edges are thick, 1/16 - 1/32, so grinding will be required. I sent mine off to Wacker in Germany for an estimate but they were lost in the mail.

The blade was not concave but rather a uniform thickness from the edge up 3/4 of the distance to the spine.

The blade was not concave but rather a uniform thickness from the edge up 3/4 of the distance to the spine.

Hope this helps,Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

09-10-2010, 03:09 PM #14

Your findings set well with the way blades are tempered. The straight cross section is to allow the removal of fire scale without grinding away the blade width. So they are done correctly. The straight section is removed during the grinding process. Now. since I only have a four inch wet wheel, I need to find someone locally with a 8-10 inch wet wheel.

~Richard

Be yourself; everyone else is already taken.

- Oscar Wilde

-

11-11-2010, 11:57 PM #15Senior Member

- Join Date

- May 2010

- Location

- Middletown, Ohio

- Posts

- 100

Thanked: 14

I have yet to have these tested. Given the cost of the tests and the fact that I do not own a grider, I have decided to put these on the back burner for a while. The only ones in the batch that are already hard are the little 4/8 ones that have company name and logo stamped on them. The larger ones are still soft and not stamped.

-

11-15-2011, 11:12 PM #16

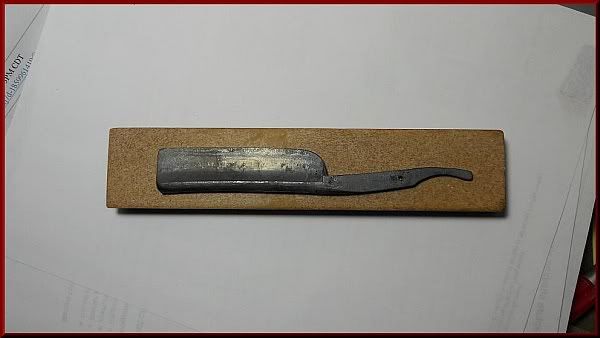

Herders Blanks are Good!

Old New Stock Herders. From the grave!

Herders Blanks are Good!

Old New Stock Herders. From the grave!

I was able to buy a few HERDER blade blanks a couple years ago. I have not yet posted the results before this due to my inexpert honing.

The blanks were rescued after WWII from the bombed out Herder’s Works. I had the blanks hardened and tempered by Mike Blue of MN. The grinding was done on a little WEN wet wheel grinder; no longer produced. Most of the work was done by hand with wet/dry abrasive papers.

I have finally learned enough to hone the blade properly with out edge crumbling. I spent many hours with it on the hones before I could. It is HARD! I scaled the blade with Cranberry Acrylic, domed ss washers and German silver pins. The first good shave was today and she is a keeper.

~RichardBe yourself; everyone else is already taken.

- Oscar Wilde

-

-

11-15-2011, 11:25 PM #17

You put a lot of work into that blank, and turned into a beautiful razor. I am impressed you ground Wen grinder.

Charlie

-

11-16-2011, 01:24 AM #18"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

The other thing learned about these blanks is that not all of them were hardened. Some came off the line before HT and some after. The easiest test for anyone at home is to try to file the blank. If the file "skates" or slips easily, the blade is hard. If the file digs in and cuts the steel, it's likely not hardened. It was a good experiment and I thank Richard for trusting me to do the job.

“Nothing discloses real character like the use of power. Most people can bear adversity. But if you wish to know what a man really is, give him power.” R.G.Ingersoll

-

The Following User Says Thank You to Mike Blue For This Useful Post:

Slawman (12-29-2014)

-

11-25-2011, 03:21 AM #19Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

Excellent!

You sure have put a lot of work into that razor and it is very nice.

Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

You sure have put a lot of work into that razor and it is very nice.

Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

11-25-2011, 04:24 AM #20Senior Member

- Join Date

- Jun 2010

- Location

- Wisconsin

- Posts

- 194

Thanked: 31

Dad, great looking razor! nice work.

14Likes

14Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote