Results 1 to 10 of 20

Thread: can this be a razor?

Hybrid View

-

12-23-2010, 02:13 AM #1Senior Member

- Join Date

- Feb 2007

- Posts

- 392

Thanked: 105 can this be a razor?

can this be a razor?

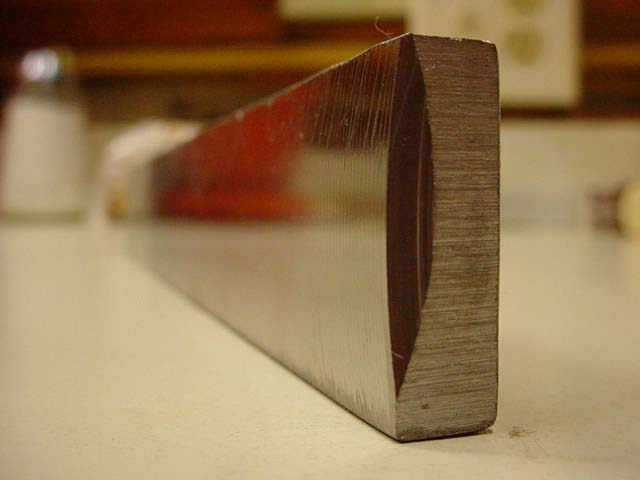

This was given to to me by a friend in the steel industry. My question is can I make this into a razor. It is 5/16 X 1 1/8 X 8 inchs.

Comp is HSLA

Carbon- .08%

Manganese-1.0%

Silicon- .025%

Niobium-.02%

Sulfur-.025%

Phosphorus-.02%

Chromium- .015%

Nickel-.10%

Copper-.30%

Molybdenum-.03%

Tin-.01%

yeild strenght 55,000 psi

tensile strenght 72,000psi

elongation 28% aproximate

What do the experts think,

Thanks for your help in advance.

TimLast edited by oldblades; 12-23-2010 at 02:18 AM.

-

12-23-2010, 03:47 AM #2Senior Member

- Join Date

- Jan 2008

- Posts

- 701

Thanked: 182

i think yes

but i hav eot look up a bit on some things

edit .08 carbon will not cut it

-

12-23-2010, 04:32 AM #3

Years ago I got this "Razor Blank" from Takeda durring one of my orders. It is an AS blank that has been annealed and sent to me...

My razor is hiding in there somewhere

-

12-23-2010, 04:59 AM #4Senior Member

- Join Date

- Jul 2010

- Location

- Central new jersey, USA

- Posts

- 728

Thanked: 240

I'm nowhere near an expert... Nor an amateur but if I remember correctly the carbon in most straight razors is significantly higher. 1.5-1.8% I believe carbon playes a huge role in the stiffness of steel so I'd say no... With the low carbon percentage the steel would probably be too soft to hold the fine edge required for a straight.... Hopefully I'm wrong.

-

12-23-2010, 05:19 AM #5

Dont the 85 in 1085 mean .85% carbon?

I seem to recall reading that here somwhere

So im more curious of how all the other ingredients influence it

-

12-23-2010, 06:32 AM #6Senior Member

- Join Date

- Aug 2010

- Location

- Vancouver, BC, Canada

- Posts

- 1,377

Thanked: 275

Try here:

All About Knife Steel, Alloys, & Steel Strength

or here:

Knife Steel FAQ

for a description of common alloys, and some discussion of the effects of alloying elements.

Charles

-

12-23-2010, 08:28 AM #7

-

12-23-2010, 04:59 AM #8

-

02-04-2011, 04:52 AM #9

ok let me preface this by saying i'm a welder/fabricator so i do have some expertise in on the subject but i have no experience making razors and i am not a machinist or a metallurgical engineer so don't take my word as law.

The particular HSLA steel is not hardenable save for possibly with ice brine though even that i doubt would yield much success. Generally a 0.6%- 0.9% carbon range is where you find the steels that take best to hardening (stainless excluded that a whole different ball game). That said you still might be able to get a viable blade out of it the copper content suggests that you probably have some sort of AR material (with out ANSI number i couldn't tell you for sure) which precipitation-hardens like a nobodies business. So opting to cold work the final stages of your blade shaping could work. If you could get me the the alloy number i could tell you more.

cheers

-Omid

-

02-04-2011, 12:35 PM #10"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

Thanks Omid, that prompted me to remember another option. A blacksmith by the name of Rob Gunter came up with a solution called SuperQuench some time ago. It's a mixture that will get the thinnest hard skin on a bar of mild steel. I don't have the recipe handy and I'm sure there are now a half dozen variations.

A good friend of mine who makes hatchets out of milder steel uses it. The hardened skin is thin enough that it will hone away much quicker than a better grade of steel. But it's something to use when you're in a pinch.“Nothing discloses real character like the use of power. Most people can bear adversity. But if you wish to know what a man really is, give him power.” R.G.Ingersoll

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote