Results 1 to 10 of 20

Thread: can this be a razor?

-

12-23-2010, 03:13 AM #1Senior Member

- Join Date

- Feb 2007

- Posts

- 392

Thanked: 105 can this be a razor?

can this be a razor?

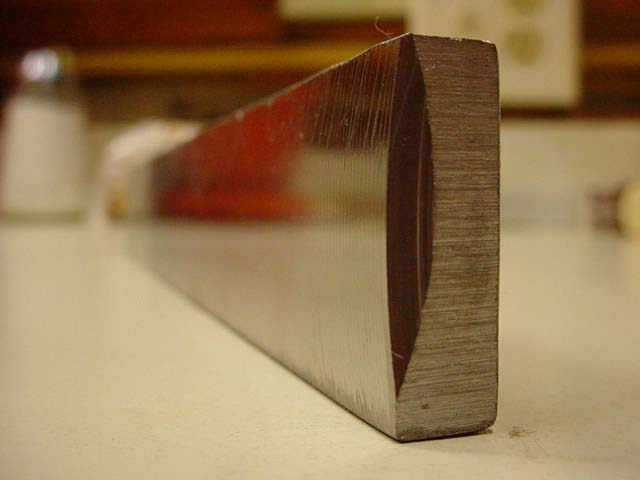

This was given to to me by a friend in the steel industry. My question is can I make this into a razor. It is 5/16 X 1 1/8 X 8 inchs.

Comp is HSLA

Carbon- .08%

Manganese-1.0%

Silicon- .025%

Niobium-.02%

Sulfur-.025%

Phosphorus-.02%

Chromium- .015%

Nickel-.10%

Copper-.30%

Molybdenum-.03%

Tin-.01%

yeild strenght 55,000 psi

tensile strenght 72,000psi

elongation 28% aproximate

What do the experts think,

Thanks for your help in advance.

TimLast edited by oldblades; 12-23-2010 at 03:18 AM.

-

12-23-2010, 04:47 AM #2Senior Member

- Join Date

- Jan 2008

- Posts

- 701

Thanked: 182

i think yes

but i hav eot look up a bit on some things

edit .08 carbon will not cut it

-

12-23-2010, 05:32 AM #3

Years ago I got this "Razor Blank" from Takeda durring one of my orders. It is an AS blank that has been annealed and sent to me...

My razor is hiding in there somewhere

-

12-23-2010, 05:59 AM #4

-

12-23-2010, 05:59 AM #5Senior Member

- Join Date

- Jul 2010

- Location

- Central new jersey, USA

- Posts

- 728

Thanked: 240

I'm nowhere near an expert... Nor an amateur but if I remember correctly the carbon in most straight razors is significantly higher. 1.5-1.8% I believe carbon playes a huge role in the stiffness of steel so I'd say no... With the low carbon percentage the steel would probably be too soft to hold the fine edge required for a straight.... Hopefully I'm wrong.

-

12-23-2010, 06:19 AM #6

Dont the 85 in 1085 mean .85% carbon?

I seem to recall reading that here somwhere

So im more curious of how all the other ingredients influence it

-

12-23-2010, 07:32 AM #7Senior Member

- Join Date

- Aug 2010

- Location

- Vancouver, BC, Canada

- Posts

- 1,377

Thanked: 275

Try here:

All About Knife Steel, Alloys, & Steel Strength

or here:

Knife Steel FAQ

for a description of common alloys, and some discussion of the effects of alloying elements.

Charles

-

12-23-2010, 09:28 AM #8

-

12-23-2010, 12:38 PM #9

For the purposes of razors you probably need a minimum 0.7% preferably 0.8% or higher carbon to get a decent hardness to hold a serviceable edge. If you get the higher carbon alloys, specialist heat treat may be required.

-

12-24-2010, 04:43 PM #10Senior Member

- Join Date

- Feb 2007

- Posts

- 392

Thanked: 105

Found out more information. This is a micro grain, high strenght low alloy steel, HSLA.

I don't know all the details, but it is made to be stronger then high carbon steel but 25 to 30% lighter and higher corrosion resistance.

Since it was free I can not go wrong to try. It will be interesting to see what happens.

Thanks for all the input.

Tim

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote