Results 1 to 10 of 22

Thread: DIY Electro-etcher..

-

10-28-2011, 01:31 AM #1

DIY Electro-etcher..

DIY Electro-etcher..

OK.. so, I know I said I was probably gonna buy one... but..this was just too easy..

Burnt out computer power supply: Free

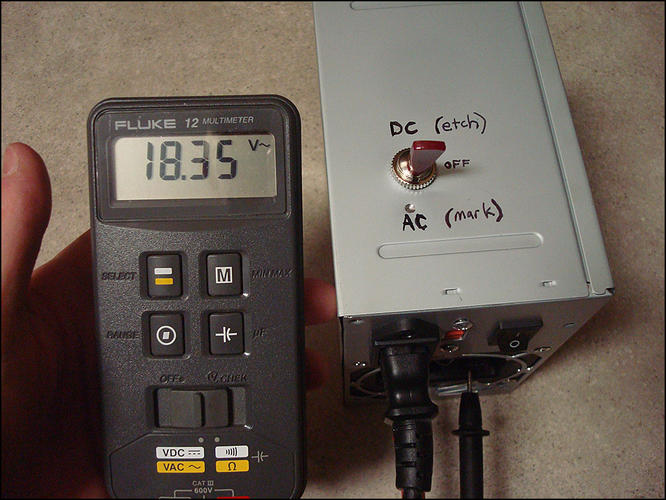

18VAC 1200mA AC Adapter (wall wart): Free (scavenged)

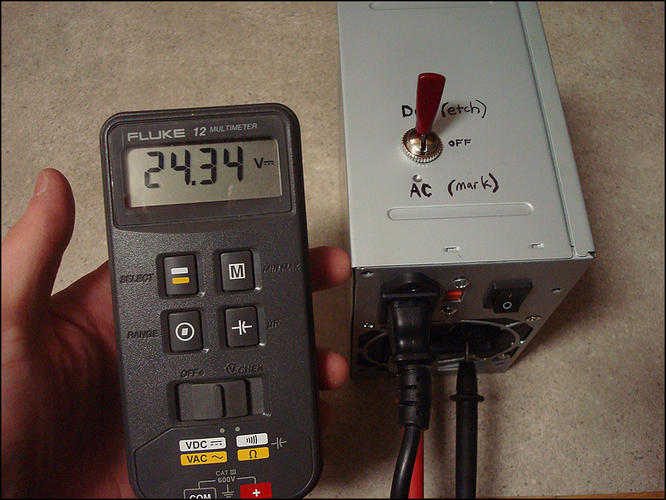

24VDC 1500mA laptop power supply: Free (scavenged)

Speaker terminal: $4.20 (Radioshack)

2-way switch (on-off-on) $3.80 (Radioshack

wire from some old computer AC cords Free (scavenged)

Total Cost: $8.00

I stripped out all the internals of the old computer power supply, and just used the 120V AC connector to wire up the two AC adapters. The outputs are soldered onto a simple switch, and I double sided taped down the AC adapters inside the box so as to make sure they don't rattle around. It worked great.

So, right now, I only have 24VDC and 18VAC... I originally had a 12VDC as well hooked up, with a second switch, but, I musta fried the adapter or it just went bad on me, because it quit working, but, I can always add it later if I find the 24VDC to be too strong. I don't think it will be a problem though, as 24VDC @ 1.5A is only 36W..and most commercial etchers go to 72W I believe.

I do have a couple questions though -- I need to solder copper wire to a small plate of stainless steel to use as the etch block.. Obviously solder doesn't stick to the stainless. What can I use to solder that wire to that steel? Does anyone know if JB Weld conducts electricity? I wonder if I could just epoxy it to the block with the copper frayed between the two surfaces.. so long as the copper was hitting the steel, I imagine it'd work..... any suggestions? You can see i have a nice piece of cocobolo for my "handle" on the block already

-

-

10-28-2011, 01:53 AM #2

While I know its not a good idea a guy I know did something that reminds me of this: he took closed terminals, crimped the wire in them and epoxied them in place. I ripped them off and drilled/ screwed them in place for him. I just had to laugh at that. I guess people just do what they need to, but if it were me I would use a screw clamp if possible.

-

10-28-2011, 05:52 AM #3

Some good info here, please keep us posted about it! I have been thinking about making an etcher, and this looks like an affordable option. I will have to read about a bit of electirity though, because here in the EU we have 230V in the connector not 120V like in the US.

-

10-28-2011, 07:04 AM #4

-

10-28-2011, 11:20 AM #5

-

10-28-2011, 09:28 PM #6Senior Member

- Join Date

- Mar 2011

- Location

- Corcoran, Minnesota

- Posts

- 665

Thanked: 170

I love projects like this. Please keep us updated on the results. I looked through one of my junk boxes, and found a 12V DC, but no AC yet. I wonder if a rheostat to cut down voltage would be a good addition? I guess time will tell. I'm really interested to see how it works!

Last edited by skipnord; 10-28-2011 at 09:43 PM.

-

10-29-2011, 09:25 AM #7

Looks promising. I might have to talk to the IT guys at work if this works

Keep us posted on the results. Thanks for posting.

Keep us posted on the results. Thanks for posting.

You might just be able to use alligator clips for the blade contact, just my completely uninformed opinion.

Good luck.

-

10-29-2011, 09:58 AM #8

Here is a link to a simple design Knife Network : Workshop - Build an Electro-Etch Machine

I am thinking a car battery charger would be ideal to convert, cheap enough and with amperage to spare

-

The Following User Says Thank You to osdset For This Useful Post:

Str8Raz0r (11-06-2011)

-

10-29-2011, 07:13 PM #9Senior Member

- Join Date

- Mar 2011

- Location

- Corcoran, Minnesota

- Posts

- 665

Thanked: 170

I am thinking a car battery charger would be ideal to convert, cheap enough and with amperage to spare

[/QUOTE]

[/QUOTE]

I'd be real careful using a battery charger. I tried using one to "reverse plating" clean a razor, and it "melted" when it accidentally touched the tin can. Way too much amperage, I think!

-

11-05-2011, 09:19 PM #10

Silver solder is definatly the answer. there are specialist companys that do this often for either specialist gas usage and air conditioning. or replacing teeth on tugsten tipped cutters though I would look for a air-con installer who will charge very little to do this job for you "its a 5 minit job" and the silver solder used in his line of work is of a lower melting point which is more suited to use with copper .Alternativly solder on a lug drill a hole in the stainless and bolt togther preferably with a brass bolt for greater electro conductivity. hope this helps.

Wiring diagram for etcher would be nice

Last edited by BertyBloggs; 11-05-2011 at 09:32 PM.

11Likes

11Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote