Results 1 to 10 of 23

Hybrid View

-

10-29-2011, 06:04 PM #1

Kerosene60 custom build Step by Step

Kerosene60 custom build Step by Step

I decided to not only show the progress of a custom but also to show how I build my razors step by step.

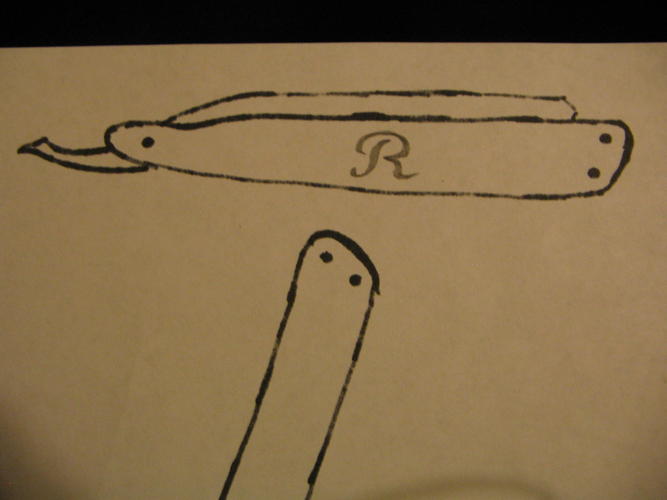

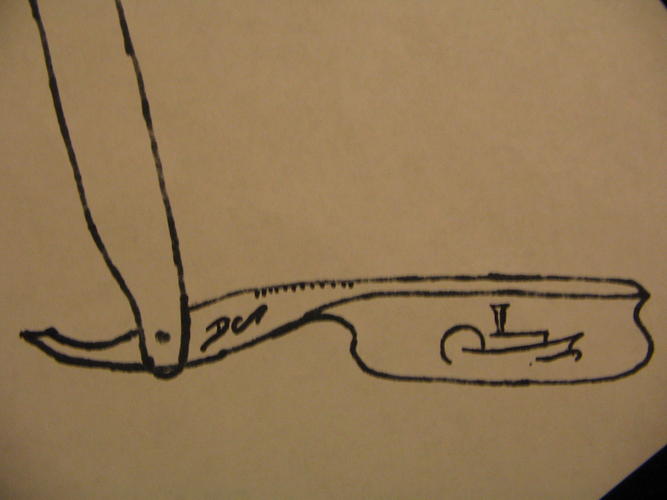

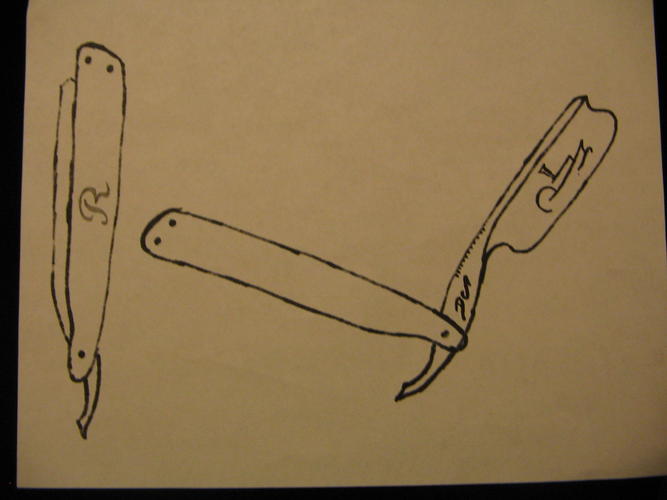

Step one design:

This step is just as it sounds, I draw the razor in full scale. The design below in the first three pics is the final design.

Step two:

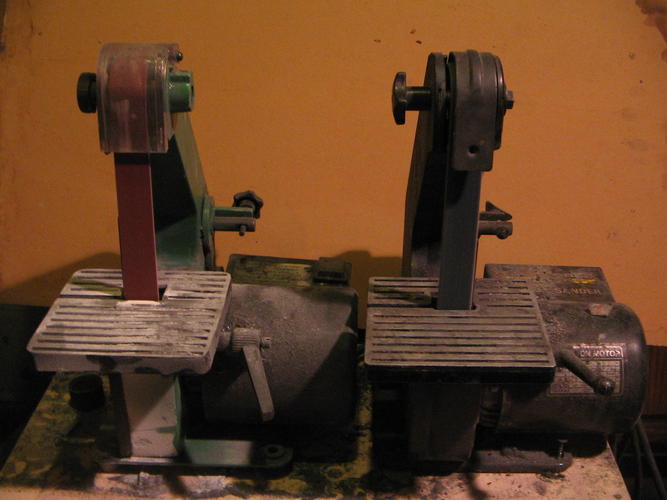

I grind the blade. I built my own hollow grinder for this. It differs from knife hollow grinders in that it turns the other direction. This allowed me to build a blade clamp that can feed the blade into the stones accurately. I can cut a blade in two passes.

Safety Note:

Grinding, power sanding, and polishing aerosols small particles of steel, aluminum oxide, carbides, and other crystal structures that are damaging to lungs, eyes, and ears. WEAR PROTECTION! Not just the normal kind either, safety glasses will not stop aerosol steel, it just floats around the sides. I use motorcycle goggles because they are designed to stop airflow. I use a washable air mask that seals to my face, this is important because ground particles are so light and small they can hide in your mask only to be inhaled later. Ear protection is a must for more reasons than I can count.

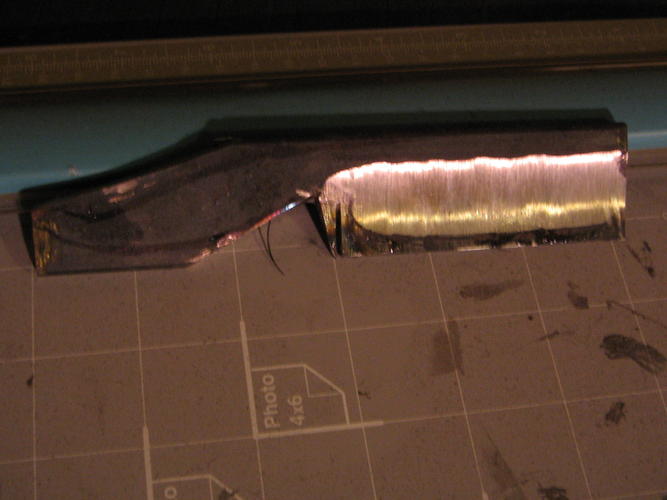

Below:

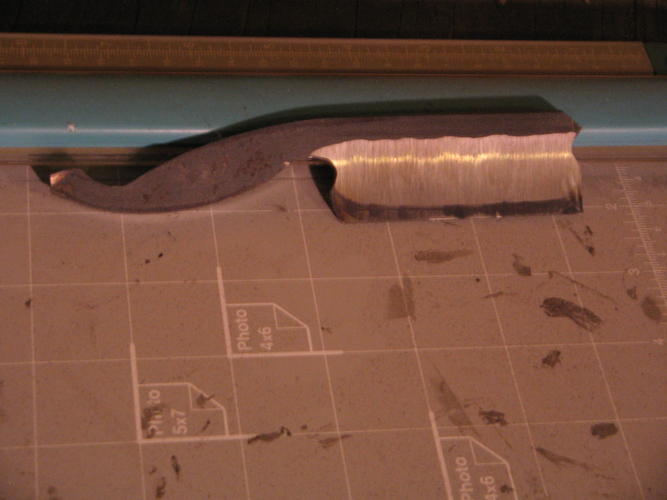

This is the rough ground blade after the second pass in the hollow grinder

I then attach, temporally, the pattern to the steel using a glue stick. I then use first a marks-a-lot then a sharpie to trace the pattern to the steel. The combination of the two lets the marking handle heat, water, and rubbing longer than either alone.

I then use a fiber cut off blade to remove as much excess material as possible.

Now I go to my sanders, for this step the sanders are loaded, one with a 40 grit the other a 80 grit belt. All I want here it the rough shape of the razor, 40g to get close quick, 80g to get closer with more caution.

below:

after the first round through the sanders.

That's usually where I stop on the blade for the first day, I take the blade to the forge and re aneal the blade and allow it to rest for at least 12 hours.

Nest time Step three the first day on the scales.

Last edited by Maximilian; 10-29-2011 at 06:29 PM. Reason: removal sales/soliciting

-

10-30-2011, 12:16 AM #2Senior Member

- Join Date

- Mar 2011

- Location

- Corcoran, Minnesota

- Posts

- 665

Thanked: 170

Thanks so much for Chapter One of your blade method. Everyone is a tad different, and we all can learn from each other. I was interested to see you using smaller 1 inch belt grinders. I use a KMG - you do your fine work with something much smaller and less expensive, and your results are excellent. Thanks again for the post. I'm looking forward to future additions.

-

10-30-2011, 11:42 PM #3aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

I like your method of starting the rough hollow before the blade shape...cool hollowing tool too!

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

The Following User Says Thank You to ScottGoodman For This Useful Post:

bishpick1 (10-31-2011)

-

10-31-2011, 06:31 PM #4

chapter 2

chapter 2

Step 3 Scales:

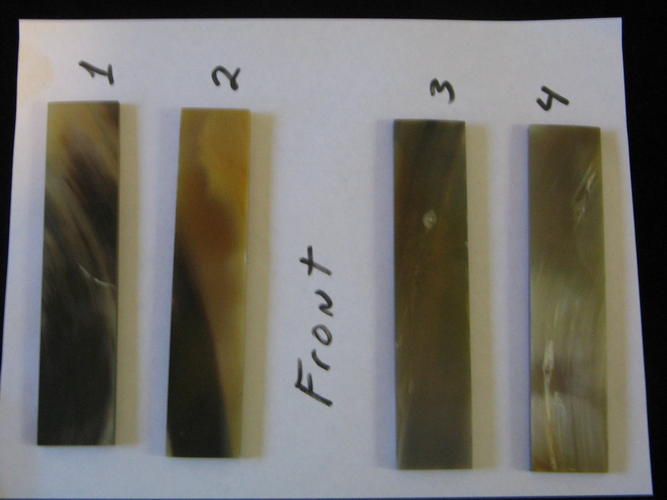

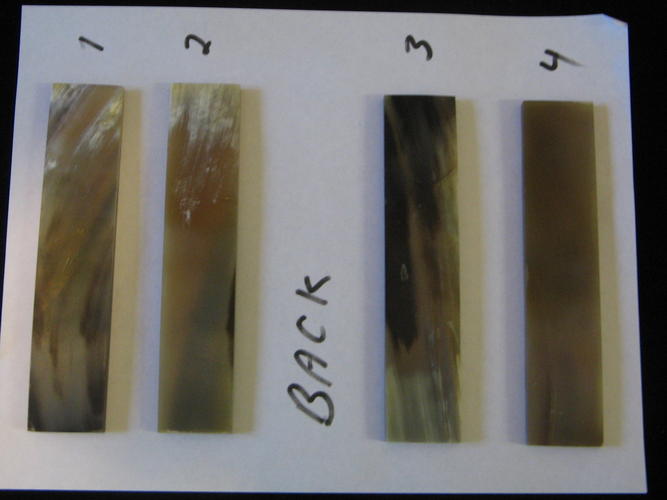

For this razor I'm using Indian blond buffalo horn, so I pick from the available horns in this case the "back" side of horn 1 and 2. Normally I only use one horn and split it two, but this razor requires 3/16" thick scales so I had to use two horns.

I trace the pattern on to the face side horn and mark the pins, I know the left side is supposed to be the face but I like a right side face. I don't know why..... Just strange I guess. I then use two sided tape to put the horns together and cut then out with a scroll saw leaving an extra 1/8" all around.

Next I'll start the inlay. For this razor I'm doing a mother of pearl inlay..... With a twist. First the materials, I get mother of pearl chips for my local craft store, I get a variety of colors, and I don't need anything larger than that so chips are perfect. I donít worry about them having been died; the die only goes a few 1/1000's deep so once I start to cut the inlay level I'll get to the real color quickly.

I attach a pattern to the chip using a glue stick (glue sticks are great because they don't hold very strong and they don't leave a difficult to remove residue).

This next pic is of one of three R's cut for this project.

I then trace the R onto the scale and dig a trench deep enough so that I won't polish all the way through the inlay.

I use a clear epoxy to set the inlay, you can see one of the pieces is still above the surface of the scale (this is before it is cut down and polished.

Here is the finished inlay. The outside stroke of the R is in four pieces made from the three pieces of mother of pearl. The different colors and patterns as well as the breaks in the inlay give it an antique feel (that's the twist). Inlays are not difficult their just incredibly time consuming and frustrating, and well worth all the trouble.

-

11-02-2011, 11:36 PM #5

Chapter 3

Chapter 3

Step 4,5,6, and 7 (repeat)

Tempering is a necessary pain in the southern regions. before I temper I sand the blade to 120 grit. then heat to critical (1550 deg.) soak for 15 min. then quench in 115 deg. oil. place in 250 deg. oven for 2 hours. let rest 24 hours, repeat, sanded to 220 grit, repeat, sanded to 400 grit. what you get is a black ugly smooth razor hardened to about 63-65 RC. (NOTE: the blade has not been cut back yet, it will be 7/8 when finished)

The pre-sanding makes the polishing much easier. the following pics show the blade polished up to white rouge. Not good enough for me, I'll sand one more time with 00 steel wool then polish with green jewelers rouge.

Last edited by bishpick1; 11-02-2011 at 11:46 PM.

-

11-03-2011, 09:41 PM #6

Just a side note

Just a side note

Just because I'm very happy with it here is some pics of my new forge

and again....

it has three air rates, First is low, which gives me HOT!

Next is Med. or WOW that's HOT!

last is of course High, or, Pits of h*#@ hot.

Just so it's relevant to the post, I did temper this razor in my new forge.

-

11-04-2011, 11:23 AM #7

That's really fantastic that you can do this. I'm impressed!

-

11-04-2011, 09:32 PM #8

Chapter 4

Chapter 4

Step 9:starting the finish work.

After polishing with green rouge I start cutting blade decorations and details. The jimps I cut with a dremel. This blade is designed around arthritic hands so the jimps are deep and wide to add control. The tang is dropped low (the tail is level with the cutting edge) for a more ergonomic grip, and the thumb notch is wide and set forward (actually set over the heel of the cutting edge) with larger than normal lower jimps. All these features are meant to allow curving fingers and reduced grip better control of the cutting edge.

Deep and wide.

The only way I could get a pic of the lower jimps was with a flash, that's why the pic looks like a negative.

The final decoration on the blade is an etched art deco river boat. Also I have now shaped the cutting edge. the blade width is a 17/16 - 9/8 - 17/16 smile. My largest blade to date

-

11-05-2011, 11:17 PM #9

Very informative and that looks like a great looking blade. Can't wait for the finished product.

Jeff

10Likes

10Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote