Results 21 to 30 of 42

-

06-27-2012, 09:02 PM #21Member

- Join Date

- Mar 2012

- Location

- Somerville, MA

- Posts

- 46

Thanked: 18

I put a more detailed construction log with more pictures up on my blog of my beginner's razor making effort, in case anyone is interested:

Tooling Up: First homemade straight razors - out for heat treating

-Holly

-

-

06-30-2012, 12:48 PM #22

-

06-30-2012, 12:49 PM #23

That said, hardening O1 is nearly foolproof.

-

06-30-2012, 01:03 PM #24

I have been using dripping water on my belts for final grinding, for me this eliminates the need to cool the razor in water and makes for a nicer grind (ymmv).

Bruno, I recently made a (fools) mistake hardening 01 by not having enough soak time. I now soak for 15 mins at 1475, which works well for me.

-

07-07-2012, 06:37 PM #25Member

- Join Date

- Mar 2012

- Location

- Somerville, MA

- Posts

- 46

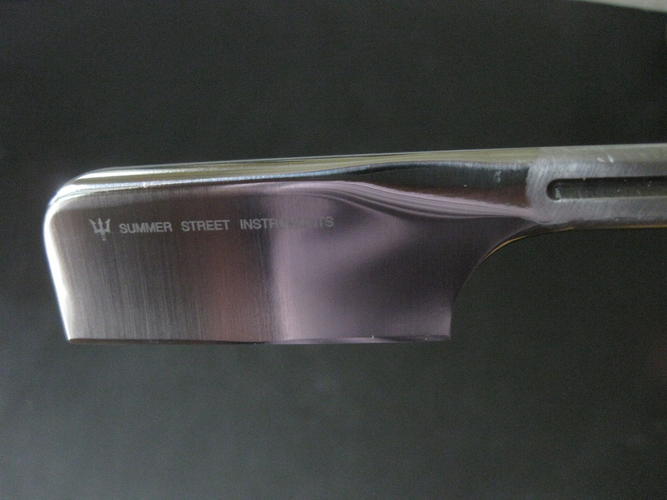

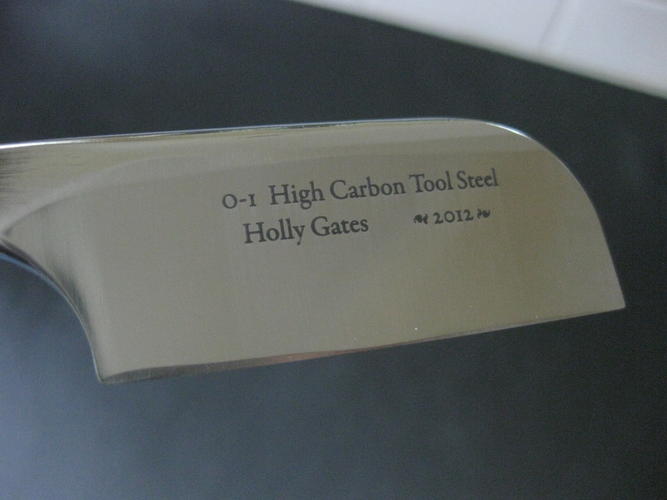

Thanked: 18 Back from heat treat - commencing secondary work

Back from heat treat - commencing secondary work

The two blades came back from Mike Blue yesterday and they look sweet. Mike said everything went fine. I got my grinder at home set up with my Caswell rubber sanding wheel and a VFD, then did a little grinding. A few snags:

- didn't realize that almost all VFDs will trip GFI circuits. I've got GFI outlets in the basement. But after I got that straightened out...

- the sanding loop won't get clamped by the rubber expander wheel unless its running at around 1800rpm or above

So I just started grinding at 1800, switching the razors in and out of a tub of water so one is cooling while I'm grinding the other until it gets hot. Hopefully I won't mess up Mike's nice heat treat.

By the way, do you grind with the edge facing up and into the wheel all the way to an edge? It seems like when you are getting close it might make more sense to flip it over and have the edge trailing. What is the best way?

Also, you really take it all the way to an edge? Seems like it will be tricky to avoid overheating as I approach the edge.

Thanks for the help everyone,

-Holly

-

07-07-2012, 07:31 PM #26

Thanks for sharing the journey Holly. I am really looking forward to the next installments.

Bob

"God is a Havana smoker. I have seen his gray clouds" Gainsburg

-

07-07-2012, 07:54 PM #27"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

Yeah, that's right. That kind of wheel needs rotation to expand the rubber and create tension on the belt. The three-wheel grinders have a tension arm or some system to take up belt slack that allows for the use of a harder rubber contact wheel where you can vary the speed easier.

My way is edge up and all the way to a zero grind....By the way, do you grind with the edge facing up and into the wheel all the way to an edge? It seems like when you are getting close it might make more sense to flip it over and have the edge trailing. What is the best way? Also, you really take it all the way to an edge? Seems like it will be tricky to avoid overheating as I approach the edge.

There is no best way, just the one you become most comfortable with. I think I have some opinions about why you should not grind edge down and that's mostly because if I can't see the edge. I have a harder time keep it all even from heel to toe if I can't watch what's happening. If you can't see the edge, it can go blue quicker than lightning. If you have time to see it, it's already too late.

But, there are a few successful grinders who do it only the trailing edge way. Then tend to stay up on top above the top half of the wheel or on the upper belt, where they can see the blade and edge, and they also reverse their wheel rotation so the sparks are all going away from them. It should be obvious that a face full of grinder swarf and hot sparks is not smart. Kinda like trying to catch bullets with your teeth...

-

The Following User Says Thank You to Mike Blue For This Useful Post:

Geezer (08-21-2012)

-

08-03-2012, 12:59 PM #28Member

- Join Date

- Mar 2012

- Location

- Somerville, MA

- Posts

- 46

Thanked: 18 Done - but won't get sharp!

Done - but won't get sharp!

Well, I've gotten to what I was hoping would be the finish point with these two razors. Definitely learned a lot. A few thoughts:

- My 40 grit belts for my 6" expander wheel last about 5 minutes before the metal removal rate starts dropping off quickly. It took me a few hours of mostly wasted time using belts which felt gritty to the touch but in fact were not cutting the metal much. These are just cheap aluminum oxide belts, and they are only 18.9" long so it makes sense they give out faster than a quality 72" long belt on a real grinder.

- I didn't realize it at the time, but apparently I had a hard time not grinding too much in the center. I was sweeping the blade back and forth over the 1.5" wide belt, trying to slightly increase pressure at either side to compensate for the fact that the middle was spending more time in contact with the wheel. When I tried to start honing, this problem became very obvious. You can see it easily in the size of the bevel in the pics.

- Razor #2 (the one with the more rounded point) ended up with the edge not parallel to the spine. So when I started honing it I saw that on one face, the nose end edge was touching but not the heel, while on the other face the heel was touching but not the nose. Probably this is partly due to the fact that I left the edge much thicker on this one before heat treating, so it had to endure much more of my inexpert freehand grinding. I think next time I would use calipers to scribe a line in the heat treating blue coating where the centerline of the blade should end up and check frequently how close I am to it from each side while grinding. I tried to fix this problem by just grinding more at the edge, and then by taking tape off and allowing some of the spine to get ground. Eventually I got at least a small amount of bevel to show everywhere.

- Though it looks cool, mirror finish is a bit of a nuisance. I didn't spend enough time on mine to eliminate all grinding marks, but even at the level I am at any little scratch shows up extremely well. I've rebuffed these a couple times after getting some scratches from stray abrasive slurry presumably pushed around by my fingers during honing.

I've spent a bunch of time honing these, but I just can't seem to get them sharp. I'm using a norton 220/1k, then a norton 4k/8k, followed by a CrOx pasted webbing strop on a flat surface. I would consider myself a beginning honer, but I can hone my one other razor (a kamisori of unknown origin) to a usable level of sharpness, and did do this alongside the two new razors starting at 4k. The kamisori came out ok, the two others just are not getting sharp.

I did try the #1 razor (more square point) after honing it last friday. I could tell it wasn't as sharp as my kamisori but I shaved with it anyway. Boy, it was very different than the kamisori, which is the only other razor I've used. Much heavier and bigger, though somehow smoother, and certainly being able to use both sides of the blade made shaving a lot easier! But it was dull enough that I had to use too much pressure and got some irritation and a substandard shave. I decided to rehone it, after buffing out some scratches I had put in the finish during the first honing. But after the second honing it was even duller.

So I can see two possibilities here:

1) I am not honing these well

In this case maybe I would send them to an expert to see if they could do anything with them. Mike did turn them into bainite, which he warned me would be abrasion resistant and thus hard to hone. But at least looking at the bevel under a loupe during honing, I feel like I am indeed cutting the metal.

2) I wrecked the heat treat during finishing

In this case I would send them back to Mike Blue for retreating and hope for the best as far as warping and decarb go. I'm pretty sure they did not get over 100C during finishing, but my fingers were not right on the edge so maybe the very edge did get too hot. Didn't turn colors at all that I noticed. Still I wouldn't be surprised if I messed it up somehow, perhaps while I was trying vainly to get my dull belts to cut.

Any thoughts?

Thanks for all the help everyone,

-Holly

-

The Following 2 Users Say Thank You to HollyGates For This Useful Post:

mapleleafalumnus (08-03-2012), spazola (08-03-2012)

-

08-03-2012, 06:36 PM #29

There is a trick for getting decent bevels:

When you are grinding the razor, hold the razor on the flat part of your belt grinder, with the spine just a bit elevated so that you are not grinding the spine.

Then gently touch the edge to the grinder, to establish a bevel. That will quickly show you where you need to even out the grind.

After you correct the grind, repeat the procedure and you'll notice an improvement. In the end, you will have even bevels.

This also works with smiling edges, though you need a bit of experience to 'roll' the razor along the spine without actually touching it to the belt.

After you are done with grinding, the bevels should be very thin. Not only is this much more elegant than fat bevels, but the razor will also be much easier to hone.Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

The Following 2 Users Say Thank You to Bruno For This Useful Post:

Geezer (08-21-2012), HollyGates (08-03-2012)

-

08-04-2012, 12:02 AM #30

I take my blade to zero (flaking) with 40 grit, checking periodicially that it lays perfectly flat on both sides along the way. Then I set the bevel with one layer of tape on my 1000 to reveal any high spots. After that I ink the bevel black and perfect it with 80 grit.

Of course there are many ways to do this.

If your not getting an edge on the razor its probably your bevel, you would know if you blew the temper, it would have been almost blueish and a small chore to grind out. IMO

Your razors look great!

Eric.

-

The Following User Says Thank You to epd For This Useful Post:

HollyGates (08-06-2012)

45Likes

45Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote