Results 1 to 10 of 65

Thread: Planning a new little forge.

Threaded View

-

10-22-2013, 03:16 AM #29Senior Member

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1184 IT'S ALIVE !!!

IT'S ALIVE !!!

Well today went well. I got up late but made up the time with some planning.

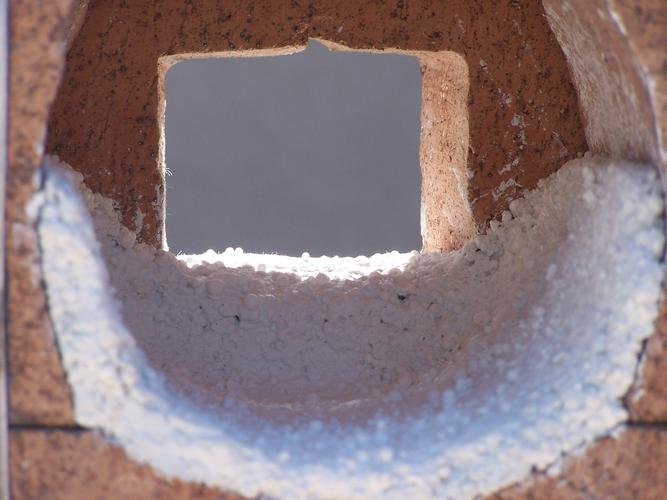

I mixed up the clay (Bubble Alumina) and went to town. It definitely was named right. The little bubbles are everywhere. The consistency was no where near what I expected and so I only did half the forge. The bottom is what counts for this type of clay anyway. I have 4 pounds of Satanite and I guess I will use that to do the top tomorrow. I hope the Satanite is more like the clay I know. I may have to stand to forge on it's head but I will get the top done. Too much heat comes through the cracks of the brick to the shell which is thin sheet metal. How do I know ? :<0)

Well while the clay set for 3 hours I ran to my metal supply guy and picked up some scrap to make an anvil stand. I got back home and whipped this out. It needs some things still, like I have to come up with a cool way to hold the anvil down and make a few hammer hangers and a tong rack. But it works . How do I know ? :<0)

I fired it up to finish the clay cure. According to the info where I bought the stuff after 3 hours you finish the cure by starting the forge and slowly bringing it up to max heat. So you can't see much in this picture but if you look close you can see the blue flame. This is as low as it will go and I let it sit there for about 20 minutes while I grabbed the rest of the stuff. What stuff ? :<0)

It got freaking HOT quick !! Then I turned it up.

Video coming soon ......apparently it was too big :<0(Good judgment comes from experience, and experience....well that comes from poor judgment.

61Likes

61Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote