Results 1 to 10 of 13

-

08-15-2013, 10:50 AM #1

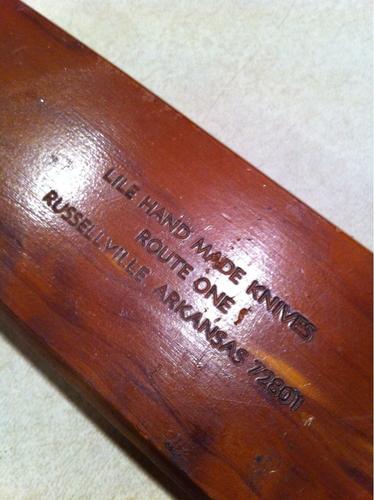

Usable for straight razors? Stone ID

Usable for straight razors? Stone ID

My dad left me this when he passed away (along with a sizable knife and less imposing straight razor collection). Curious if it could be put in service for straights...

There is no indication of grit...it's smooth as glass.

I haven't done a web search yet, but will...---------------------------------------------------

Love new things that look old, and old things, made to look new again!

-

08-15-2013, 02:31 PM #2

Looks Like an Arkansas hone!

"Don't be stubborn. You are missing out."

"Don't be stubborn. You are missing out."

I rest my case.

-

08-15-2013, 02:37 PM #3

That will probably work fine for razors, give it a try!

Hur Svenska stålet biter kom låt oss pröfva på.

-

08-15-2013, 03:18 PM #4Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

What size is it?

Looks like a nice older large Black with some translucent occlusions. There were a lot of those stones marketed in the 60 & 70’s in similar Cedar boxes, they are great stones.

Put a knife edge to it and look at the bevel. The good ones will leave a Hazy, Kasumi bevel. There is a lot written on using Surgical Black Arks or Arkansas Finishing Stones. They can be very nice finishers if you take the time to learn them, stone prep and lots of laps. Back in the day, before synthetics they were state of the art and coveted finishing stones. They still command a few dollars.

It is one of the stones I like to shave straight off of, no stropping. To me it is a unique edge, keen yet comfortable.

-

08-15-2013, 04:30 PM #5

Excellent!! Not sure how I could have missed that...

Time frame would be right. My dad would have bought this around the early to mid 70's. Probably never used it.

I have Norton 4/8 coming which I was planning to use exclusively, ala JaNorton, but sounds like this might make a good addition. I don't have it here with me, but I am going to call it 8" by 2.5".

I would think it would be wise to lap it before I use it?

Water or oil? Does it matter? I would expect I can soak it; it's fixed to the cedar base.---------------------------------------------------

Love new things that look old, and old things, made to look new again!

-

08-15-2013, 06:10 PM #6

Google search "Lile Hand Made Knives". These are fine hand crafted knives. The stone is quite a find. Enjoy

-

08-16-2013, 04:07 AM #7'tis but a scratch!

- Join Date

- Oct 2010

- Location

- Durango, Colorado

- Posts

- 2,080

- Blog Entries

- 2

Thanked: 443

Here's a good thread on prepping Arkansas stones. See this post especially; I used the technique on a Charnley Forest (same mineral as Arkansas hones) and converted it from a regrettable purchase into a really superb hone.

Check the flatness against a really good straight edge (Starrett or better) or a machinist's reference block before you invest the time in lapping it flat. If it's already flat you can save an irretrievable week of your life.

Best wishes and enjoy that hone!"These aren't the droids you're looking for." "These aren't the droids we're looking for." "He can go about his business." "You can go about your business."

-

08-16-2013, 10:19 AM #8

Excellent info!! Thank you.

How might I determine the approximate grit? The thread you linked to makes passing mention to 4000. I want to purchase complimentary stones.. Don't want to buy a Norton 4/8 if this one is close to a 4k...

So far, all I have been able to find is this chart that puts the grit at "1200+'. Not a big help.Last edited by MikekiM; 08-16-2013 at 10:29 AM.

---------------------------------------------------

Love new things that look old, and old things, made to look new again!

-

08-16-2013, 12:20 PM #9

Congratulations MikekiM, surgical black and black translucent Arkansas stones can be used for finishing straight razors. They are used with oil. They are slower (100 min to 200+ passes) and tend to leave a toothy edge or micro serrations. Proper stropping or a pasted strop can smooth the edge. Thank you for sharing.

Mike

Lil dab will do.

-

The Following User Says Thank You to MODINE For This Useful Post:

MikekiM (08-16-2013)

-

08-16-2013, 01:16 PM #10'tis but a scratch!

- Join Date

- Oct 2010

- Location

- Durango, Colorado

- Posts

- 2,080

- Blog Entries

- 2

Thanked: 443

Grit size, though discussed all the time, doesn't really apply with many naturals. Novaculite hones work to their top potential when polished smooth by a flat steel face, as described in the post I linked to last night.

You should still get a 4/8 if you're interested in honing.

Best wishes"These aren't the droids you're looking for." "These aren't the droids we're looking for." "He can go about his business." "You can go about your business."

-

The Following User Says Thank You to roughkype For This Useful Post:

MikekiM (08-16-2013)

4Likes

4Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote