Results 11 to 20 of 51

Threaded View

-

11-10-2013, 03:17 PM #1Junior Member

- Join Date

- Aug 2013

- Posts

- 17

Thanked: 1 JNAT & Nagura questions/identification - help!

JNAT & Nagura questions/identification - help!

Hi Everyone,

Fairly new member here, some great content on this forum!

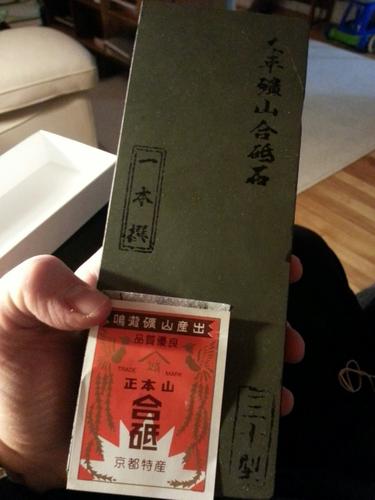

Hoping someone can give me a quick read on a JNAT and nagura that I picked up (from a mate), I'm wondering what I have and their suitability to razor honing (particularly for an iwasaki kamisori)

I'm familiar with razor honing, but not on natural stones.. some of you may be familiar with the term in golf - "$100 gear, $10 swing" - and may be thinking it's applicable here but I'd really like to learn how to use a natural stone.

but I'd really like to learn how to use a natural stone.

One of the nagura is a very dark almost black, but in certain lights I see ruby/dark red highlights - not seen one quite like it before.

The box the stone came in just says Oohira 30 (30 I assume refers to size?) and "very hard".

Any help or advice would be very much appreciated!

Thanks!

Chris

11Likes

11Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote