Results 11 to 20 of 20

Thread: My first Gold Dollar honing

-

01-11-2014, 10:58 PM #11

I'm having problems visualising what you're saying. Do you have a few photos??

-

01-11-2014, 11:16 PM #12Historically Inquisitive

- Join Date

- Aug 2011

- Location

- Upstate New York

- Posts

- 5,782

- Blog Entries

- 1

Thanked: 4249

Im having a hard time figuring out how does one goes from a bevel setting stone, to a Phig and get a shave ready edge?

Most Phig users use 150 laps+- after a normal progression, some even more...

-

01-11-2014, 11:17 PM #13

I don't have any pictures ATM, But I can try get some done this weekend and post them up

-

01-12-2014, 03:34 AM #14

What a curse be a dull razor; what a prideful comfort a sharp one

What a curse be a dull razor; what a prideful comfort a sharp one

-

01-12-2014, 05:14 AM #15Historically Inquisitive

- Join Date

- Aug 2011

- Location

- Upstate New York

- Posts

- 5,782

- Blog Entries

- 1

Thanked: 4249

-

01-12-2014, 05:49 AM #16

Last edited by Steel; 01-12-2014 at 05:55 AM.

What a curse be a dull razor; what a prideful comfort a sharp one

-

01-12-2014, 01:29 PM #17

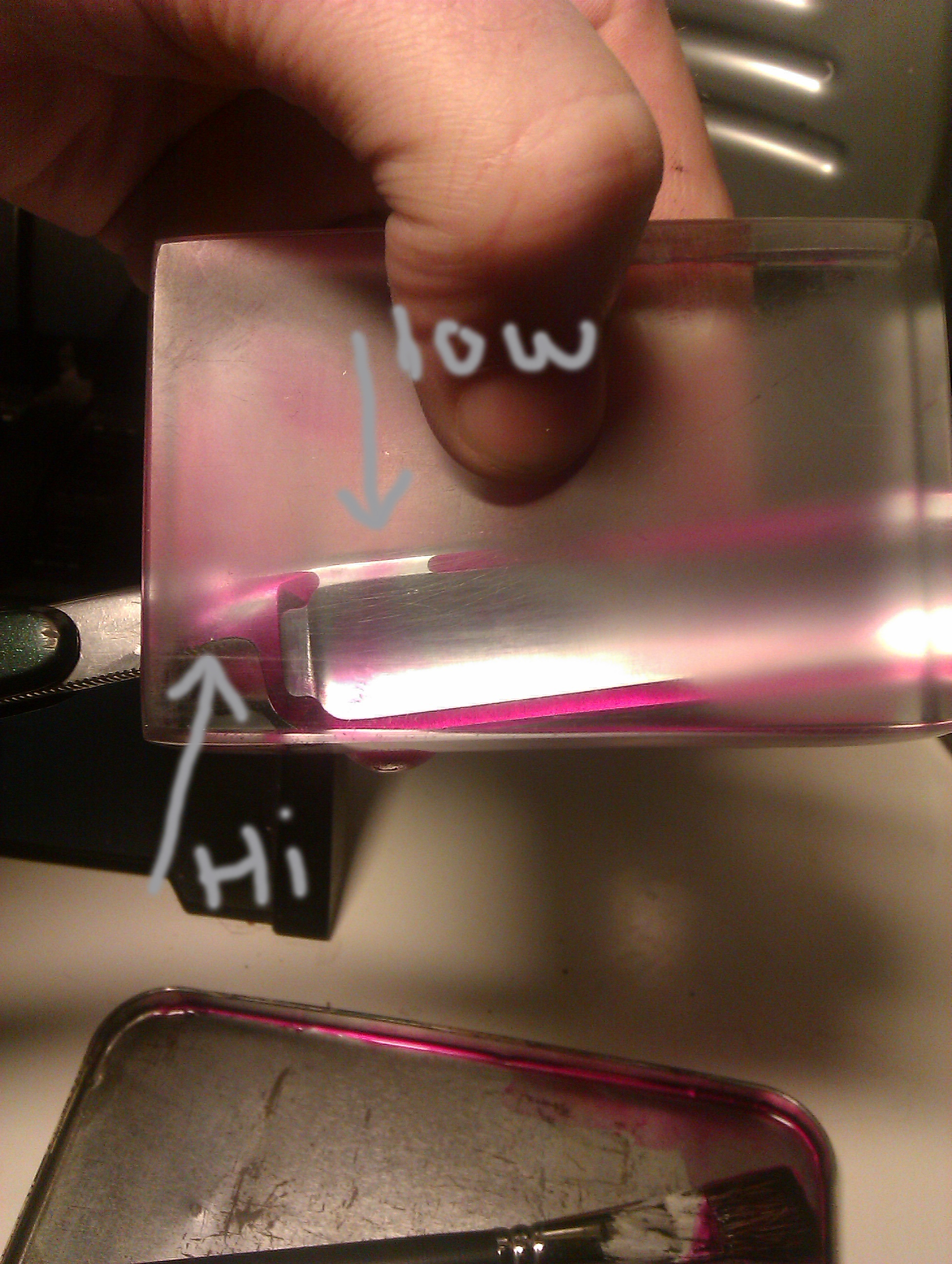

Ok here's how I've been using the block.

The razor is pretty much set, I've had to pull the block way over onto the tang to simulate the problem. And The Dye I used is also a lot more concentrated than I would usually use. It should give you an idea of how I'm using the block tho.

-

01-12-2014, 03:27 PM #18Historically Inquisitive

- Join Date

- Aug 2011

- Location

- Upstate New York

- Posts

- 5,782

- Blog Entries

- 1

Thanked: 4249

Iceni, why did you have to modify the tang on that razor?

-

01-12-2014, 04:04 PM #19

The shoulder had a shallow grind, That's the good side that didn't need much attention, The other side both shoulders were high at the spine. The main reason I had to modify into the tang was my files were too wide to do the work without touching either the blade or the tang, So I choose to sacrifice the tang. The shoulder on the other side is also not ground perfectly up down, The spine side of that first shoulder sits over part of the shaving edge.why did you have to modify the tang on that razor?

The shoulder had a shallow grind, That's the good side that didn't need much attention, The other side both shoulders were high at the spine. The main reason I had to modify into the tang was my files were too wide to do the work without touching either the blade or the tang, So I choose to sacrifice the tang. The shoulder on the other side is also not ground perfectly up down, The spine side of that first shoulder sits over part of the shaving edge.why did you have to modify the tang on that razor?

I made the problem initially worse with my attempt at using a DTM to try get back the toe. All I did was cause more of a lump out of the lump that was already there. Without the block I don't think I would have got it.

That razor is now relegated to a letter opener. I have the 2 bismarcks now and have learned my lesson. All honing is now done for me in this order.

Check geometry on glass, Hone with tape, finish on a crox strop. I'll never get another cheapo again but what it's taught me has been very important.

Last edited by Iceni; 01-12-2014 at 04:13 PM.

-

01-12-2014, 04:17 PM #20

This is where vintage steel, in nearly any condition, is a bit ahead of the brand spanking new products from some points of the map.

It's all for the hairs on our chinny chin chins!

(thanks for the visual, i've been meaning to pick up some glass-but also I have a 24x36" surface plate in the shop.)

19Likes

19Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

but it really wasn't hard at all. I just followed the same progression as I saw Glen do in the video and of course stropped on crOX and leather and it worked just fine. Those Guangxi or Phigs are pretty versatile I guess.

but it really wasn't hard at all. I just followed the same progression as I saw Glen do in the video and of course stropped on crOX and leather and it worked just fine. Those Guangxi or Phigs are pretty versatile I guess.