Results 1 to 8 of 8

Thread: Lapping up my first 12k hone

-

02-01-2014, 05:27 AM #1Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,456

- Blog Entries

- 1

Thanked: 4207 Lapping up my first 12k hone

Lapping up my first 12k hone

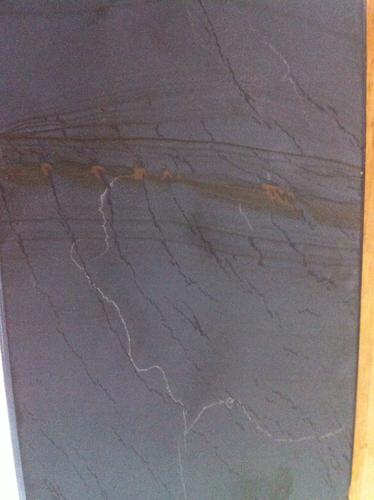

Evening gents. Just finished lapping up a cnat 12k natural stone I picked up off eBay from Poland after reading up on the stones results from all the threads on here. Great info from engaged members that really helped, so cheers to all of you for that.

Took me over 6 hours between my lapping block, 240 grit sanding disk, and my1k king stone.

I lapped both faces and both long sides as well.

Really worried about the crevice or seam on what I expect to be the A surface, but by the time I was done it was almost invisible and can't be felt. The B side started to look feel really glassy and has those cool goldish looking areas so it may end up being the finer side, i have no idea if all that multi coloured area is a good thing or a bad thing on a natural stone. Will find out when I finish my first few blades and will advise.

cheers!

-

02-01-2014, 06:59 PM #2Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,456

- Blog Entries

- 1

Thanked: 4207

Follow up on my new stone is that I may have more to lap.

When fully dried I can easily feel the fissure line on what I'm calling the A side.

The other side, while being much more colorful, feels slightly uneven across all those patterns, again, when fully dry today.

When wet, both sides seem glassy smooth, but I haven't tried a razor yet, just finger and thumb.

Any thoughts? Should I stay with the 1k king, go back to the lapping block or just try a razor and see in your folks opinions.

Thanks gents.

-

02-01-2014, 07:24 PM #3

I haven't seen a Cnat that looks like that yet. Very nice looking stone. Mine took ages to lap also. It broke in a DMT plate nicely.

I think if you can feel the difference within the stones that might mean that the color sections my be rougher. Hopefully someone with more experience with a wider variety of these stones with see this. Some people on here had to go through a few of these before they found one that works. I would say try it out and see how it works. Again very interesting looking stone. Oh no I hope I don't turn into a rock hound cause that will cost me.

I think if you can feel the difference within the stones that might mean that the color sections my be rougher. Hopefully someone with more experience with a wider variety of these stones with see this. Some people on here had to go through a few of these before they found one that works. I would say try it out and see how it works. Again very interesting looking stone. Oh no I hope I don't turn into a rock hound cause that will cost me.

-

02-02-2014, 05:15 PM #4Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Nice looking stone, in the future loose silicone will make it flat in a short time then remove the scratches with wet & dry up to at least 1K. Wet & dry go quickly once flat.

I have had great result finishing C12k’s like Ark’s by burnishing with hard flat steel, carbon steel kitchen knives or plane blades with lots of pressure and a bit of soapy water. 2-400 laps will leave a glass smooth face and the best performance from a C12K even if it’s not 12K.

Nice find, what size is it? Looks large.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

MikeB52 (02-03-2014)

-

02-02-2014, 06:59 PM #5

P-nat? (poli-nat)

E-nat? (euro-nat)

ROE-nat? (rest of europe or non-Belgium nor German)

it ain't 12k. Let's attempt to begin to try to stop perpetuating the misnomer*.

DRAG some dang steel across that thing! As a shave test is to a final edge, a stone can only be tested with steel. Don't you have some "second-class" or "problem child" razors to play with? need one?

Looks good from here. I hope to do some happy honing today. I found my sink already. I knew about where it was...

*of ascribing any grit-rating to naturals of course. If i had the equipment, i'd rate natural stones by the extremes of the range of finishes they would produce on a sample of razor steel. IOW, slurry it up work a bevel over with good pressure-then measure the resultant finish (however these things are done). Then clean it up and work to the best cleanest final finish one could muster--and measure that finish. There'd be your range for that particular natural , and your technique/skills (on that particular slab of steel). Then that range could be compared to manufactured stones "for reference" if one still desired.

sorry for the drift, but the first load of java just kicked in...

Last edited by WadePatton; 02-02-2014 at 07:17 PM.

Buttery Goodness is the Grail

-

The Following User Says Thank You to WadePatton For This Useful Post:

MikeB52 (02-04-2014)

-

02-02-2014, 08:18 PM #6Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,456

- Blog Entries

- 1

Thanked: 4207

The stones 8x3x1 and I purchased from razor_pl on eBay.

The below is my first attempt on a razor, a 'second class' blade from a company in Cleveland. Loved the scales on it.

So I worked the A surface with the slurry stone, hard pressure and 200 laps to generate the milk as seen. The slurry lasted for an entire 100 lap run, very little water absorption.

B side, same slurry technique generated zero milk. Seemed super harder surface.

Same 100 lap run and the stone didn't absorb anything, or very, very little.

Compared the resulting edges and the slurry able side seemed slightly matt finish, the other side, near mirror.

Only have a 30x loupe to see by and haven't shaved yet, but happy with the initial results visually..

Will advise as to the shave.

Thanks for the feedback folks. Now I need to find a source for silicone.

Cheers.

-

02-06-2014, 12:58 AM #7Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,456

- Blog Entries

- 1

Thanked: 4207

2 razors honed, and 2 shaves in and I definately have improved the comfort and smoothness of these 2 blades.

Swedish Red Devil and TI vintage LeDandy both honed with the slurry to clear method for 50 laps on the one side, then 50 just with water on the marbley looking side and I have a highly polished edge that only reflects one or two deeper scratch lines from bevel set, everywhere else is mirror shine.

A few laps on crox on felt then 100 on the leather. That's it.

I did bring a steel bar home and worked both sides of the hone a few 400 laps with a spot of detergent as suggested just in case. And it certainly didn't hurt..

Thx for the tips all.

-

03-20-2014, 06:29 AM #8< Banned User >

- Join Date

- Jan 2009

- Location

- Seattle,Wa

- Posts

- 103

Thanked: 2

The Japanese have a great habit of using a hone of a different grit and using them to rub together to get both smooth. Then rinse well

8Likes

8Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote