Results 1 to 10 of 382

Thread: Hard Arkansas

Hybrid View

-

09-13-2014, 06:10 PM #1

It is basically the same lapping and burnishing process used on any hard stone or barber hone.

lap the stone flat with your preferred method, most use a dmt 325. Wet and dry paper on a counter or piece of glass will substitute.

Continue lapping up the grits as far as possible.

For final burnishing use another hard high grit stone or a large bit of tool steel. Tool steel is not hard enough to do this quickly so I suggest a 1x3 ark to burnish and later raise a imperceptible slurry. Don't expect good results using ark slurry with razors, but great results can be had with other less sensitive edges. I usually use about 200 passes to burnish and ~50 to raise an arkie slurry.

JonathanSHHHH!!!! It's "respect for the age of the blade", NOT laziness! - JimR

- JimR

-

The Following User Says Thank You to Datsots For This Useful Post:

Biggreg (12-03-2014)

-

09-14-2014, 06:47 AM #2Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

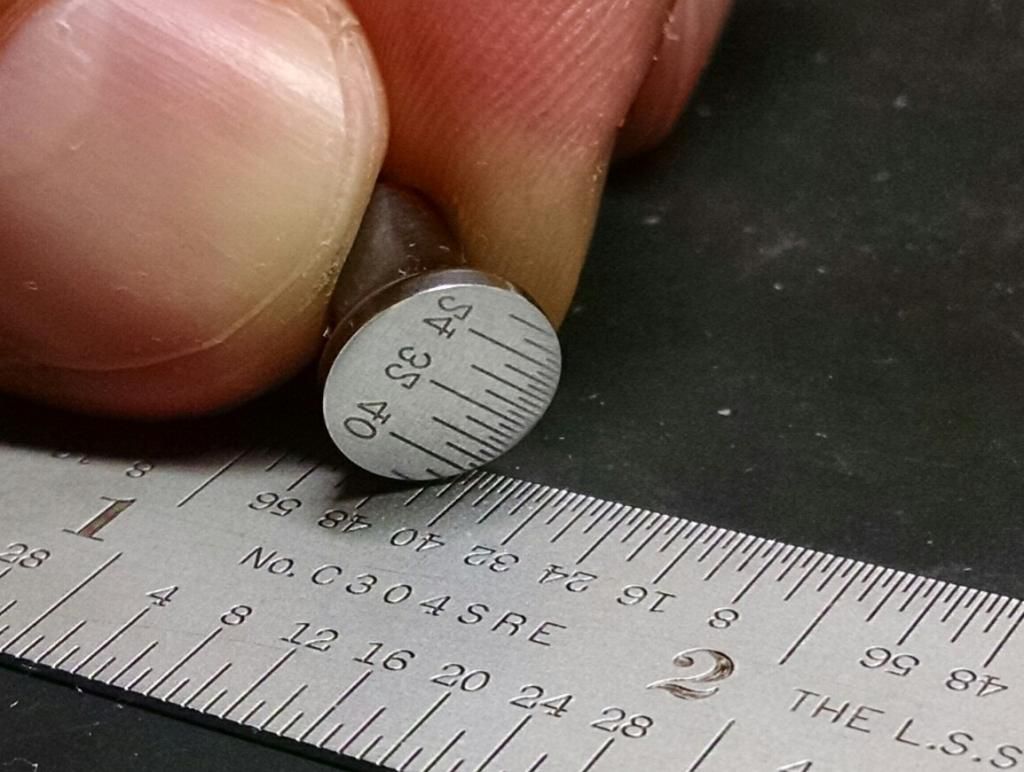

I've had some interesting results playing around for a few hours today with my Translucent Black Arkie. I tend to experiment a lot and teach myself things, always have, most likely always will. Anyway, using my little finish test piece (hardened steel, about 3/8" in diameter, flat on end where I check stone finishes) I tried a few different finishes and moved them all to the Ark last. Now one side of mine I lapped at 120 grit and leave it there, the other is a near mirror. I also relapped the finer side today, and tried a new finishing method - SG20k lapping! Worked pretty well actually.

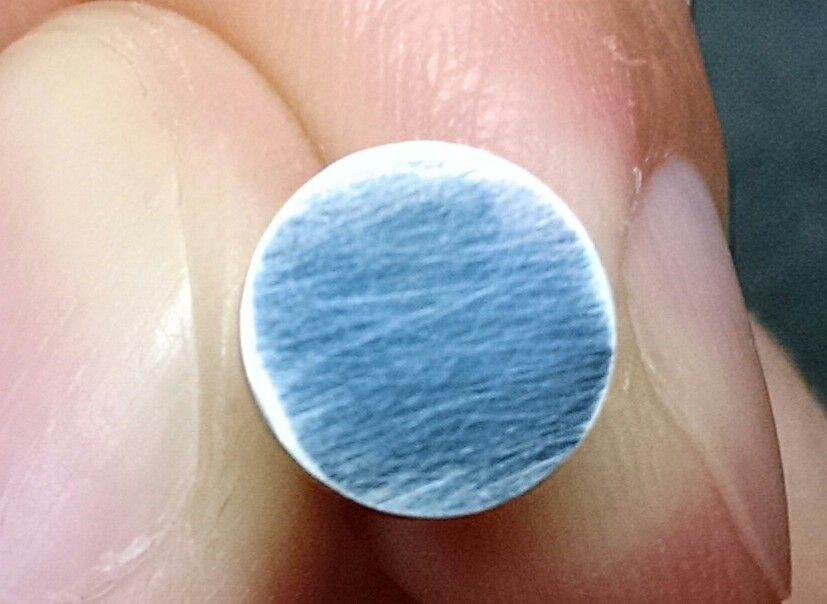

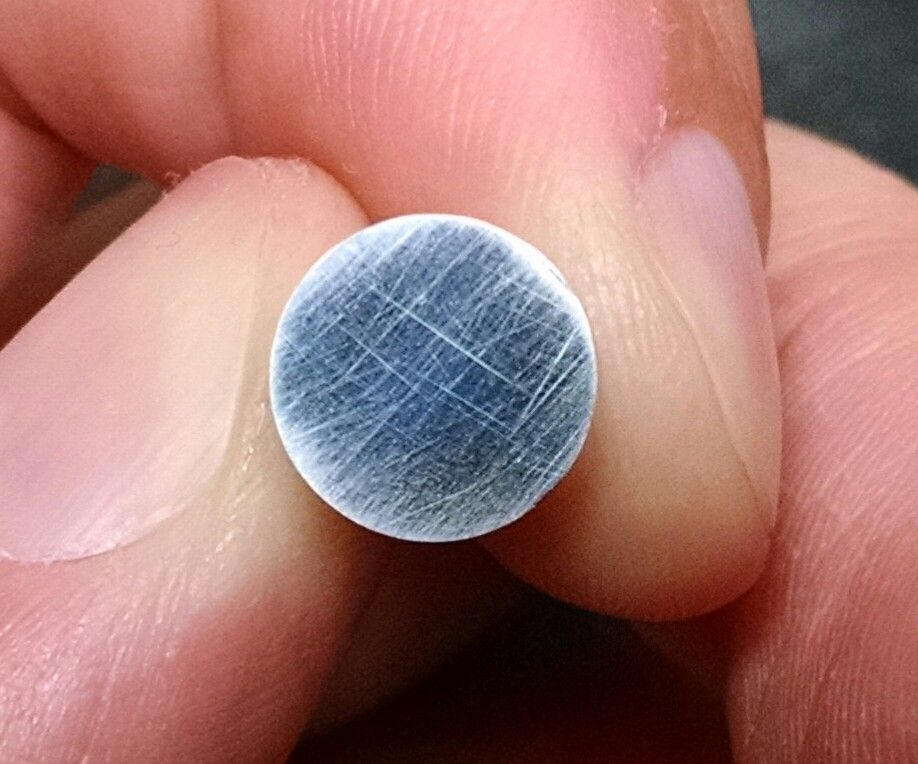

I lapped on silicon carbide first up to 1500, then flattened the SG20k with an Atoma 140. Left the slurry from flattening on the stone and then used it to basically loose grit lap the Arkie with SG20k grit particles. I reflattened/refreshed the slurry on the SG20k about 5 times and spent over an hour on just this final operation. Here's how she looks now (these are both completely dry stone pics - no liquid or oil on the surface):

Anyway, went through a whole lot of different lubricants and liquids, tried water, synthetic ATF, water with dish soap, Tap Magic cutting oil, mineral spirits, even lighter fluid. Some make the stone cut coarser and some finer, but I had never been able to get much beyond a hazy mirror finish.

Until today, when I found it. Using the Tap Magic, I applied 3 drops to the stone, then wiped it all back off with paper towel as dry as I could. Starting from a 1500 grit Suehiro synthetic waterstone as my baseline finish, I honed the test piece on the coarser side of the Ark until all the Suehiro scratch marks were gone. After that, I flipped the stone to the fine side and used the same process with the cutting oil as I had on the coarser side.

Lo and behold - a bright shiny mirror began to emerge! There's a trick to keeping it though - after every 30 strokes or so, wipe off the swarf (which amounts to a very barely light gray haze on a white paper towel) and add 3 more drops of Tap Magic and wipe it off. The surface just continued to get better and shinier/brighter the more I did it. If you just keep honing and don't do this step, the finish starts to cloud and goes back to the hazy mirror.

I think using the right method this stone might well be able to give the SG20k a run for its money. I will take some pics of the SG20k finish vs. the Trans Black Arkie and add them shortly.Last edited by eKretz; 09-14-2014 at 07:07 AM.

-

The Following 2 Users Say Thank You to eKretz For This Useful Post:

Blistersteel (09-14-2014), earcutter (09-14-2014)

-

09-14-2014, 08:11 AM #3Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

OK here we go. I took some pictures to try to compare the finishes, trying to show both the clarity and also the absolute worst that I could make them look with the scratches caught in the light just so. These were finished as omnidirectionally as possible - with back and forth, side to side, circular and figure eight strokes.

SG20k:

Translucent Black Ark:

SG20k:

Trans Black Ark:

SG20k:

Trans Black Ark:

Not quite as fine a finish with the Ark as with the SG20k, but very much closer than most people probably think is possible. However the Ark took at least 5 times as long to get to a finished surface as the SG20k. That puppy cuts amazingly fast for being so fine. Now I need to try a razor with this method and see how it shaves.

-

The Following User Says Thank You to eKretz For This Useful Post:

earcutter (09-14-2014)

-

09-14-2014, 04:00 PM #4

Thanks eKretz!

Your rock looks awesome btw - and your insights are a great read! I'll be very interested to hear what your face says.

I have been using my Black on a variety of different blades for the past month or so. I can't believe the results. As in, they have been great on just about every blade I have used it on so far.

I haven't used anything but the oil the vendor provided. I noted too that the blades had a haze unless I replenished the oil often. It was great reading you found that to be the case too. That said - I haven't been able to distinguish the difference between them on my face - which is great because replenishing the oil often is kind of a drag lol.David

-

09-14-2014, 05:05 PM #5Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

Thanks! Yeah I'm not real sure whether the haze will make a difference to the shave feel, but will be trying both ways to see if there's a difference to me. The haziness seems to be related to the swarf acting as a sort of lapping grit. As the swarf starts to come off and cover the stone, I believe it rolls and slides between the steel and the stone, giving the little micro-pitting and haze that's visible under magnification. Removing the swarf early and often helps prevent that micro-pitting and haziness for sure. However, that swarf may act like the slurry from a JNAT and smooth the edge, so removing it may make the edge sharper but more harsh.

-

09-14-2014, 05:22 PM #6

275Likes

275Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

. Was really attractive but - it was a bit too crisp for me. Since then it has been from rock right to leather. Smooth!!

. Was really attractive but - it was a bit too crisp for me. Since then it has been from rock right to leather. Smooth!!