Results 1 to 10 of 16

Thread: Raven Barber Hone

-

09-02-2014, 10:54 PM #1Senior Member

- Join Date

- Mar 2014

- Location

- Finger Lakes region of New York State

- Posts

- 532

Thanked: 49 Raven Barber Hone

Raven Barber Hone

Just received my first barber hone in the mail today. I saw one of these a few months ago and fell in love. No chips that I can see so far. Seems very flat and the bevels are intact. Box is in good shape too.

There is a slightly sticky residue on it which I assumed is old oil. Also a couple of blemishes which I am hoping are just hardened residue although I haven't been able to pick them off with my fingernail.

The instructions say to clean it by rubbing it with fine emery paper. I really don't want to do that and was wondering if I could just clean it with dish soap and hot water?“To be fair, I did have a couple of gadgets which he probably didn’t, like a teaspoon and an open mind.”

-The Doctor

-

09-02-2014, 11:02 PM #2

I would just hit it with a toothbrush & some dish soap.

-

The Following User Says Thank You to Hirlau For This Useful Post:

tedh75 (09-02-2014)

-

09-03-2014, 12:49 AM #3Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

I had one of these quite a few years ago. Lovely looking hone.

I tried it as-is with no problems, nice hard stone (or so I thought) but it felt a bit sticky and had some little pits, so I finely lapped it, sold it and forgot about it.

Turns out it "softened up" and lost the power to hone, even a fingernail marked it! Returned the buyers money, of course, but could not work out why it went soft.

Some time later while I was researching another barbers hone, I found out that some were baked in an oven (called hot hones) and some were made with resin, like shellac, and poured into a mould and left to set (called cold hones).

It seems that some of the cold set ones reverted back to being soft under certain conditions, and that removing the fine surface layer exacerbated the effect.

From that I concuded that my raven hone was of the cold type.

I am not saying yours is the same, indeed, the logo looks a little different from what I remember, so maybe mine was an earlier version and they changed to a hot baked ceramic type mix.

What I am saying is that if it works do as Hirlau says, just clean it. Pits, being below the surface will not affect honing, so try to refrain from lapping the surface. The surface is a film of finer particles, a "fatty" layer called laitance. Removing it reveals a slightly more open, slightly coarser matrix - so in many cases lapping is a bad choice.

Still, don't panic - yours may well be fine.

Regards,

Neil

-

The Following 5 Users Say Thank You to Neil Miller For This Useful Post:

Blistersteel (09-03-2014), Leatherstockiings (09-03-2014), lz6 (09-03-2014), tedh75 (09-03-2014), Wolfpack34 (09-03-2014)

-

09-03-2014, 01:00 AM #4

After reading this I had to break out my Raven and see if my fingernail could mark it....Luckily it didn't. I haven't used it much, along with my other barber hones. Usually just go to my 12k when I need a touchup.

I choose death before dishonorI'd rather die than live down on my knees

I choose death before dishonorI'd rather die than live down on my knees

-

09-03-2014, 03:29 AM #5Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,450

Thanked: 4829

I think that John's toothbrush and a little soap is a great place to start. I don't see the point in spending a bunch of time on unneeded tasks.

It's not what you know, it's who you take fishing!

-

09-03-2014, 09:39 AM #6Senior Member

- Join Date

- Mar 2014

- Location

- Finger Lakes region of New York State

- Posts

- 532

Thanked: 49

I cleaned it up with the toothbrush and dish soap. Overall it seems to be in good shape, but with the gunk off I am able to see a few small pits. I don't intend to lap it especially after reading Neil's post. If this one turns out to be going bad it will just be a novelty piece.

I mainly use my 12k for refreshing as well, but I definitely want to try the barbers hone even if it is only for nostalgia's sake. I did five laps on it with my Robeson shuredge, then stropped about 200 times. Normally I do 100, but I often find the second shave after I've honed to be smoother than the first so I thought I would try more stropping.

I had intended to try out the edge last night, but it got late quick so I imagine I will use it tonight.Last edited by tedh75; 09-03-2014 at 09:42 AM.

“To be fair, I did have a couple of gadgets which he probably didn’t, like a teaspoon and an open mind.”

-The Doctor

-

09-03-2014, 10:47 AM #7

My recently acquired Zulu Grey has taken over where the Naniwa SS 12k did duty as a touch up stone. I won't be surprised if the Zulu becomes more and more popular as time goes on. It is a really nice stone.

-

09-03-2014, 10:47 AM #8

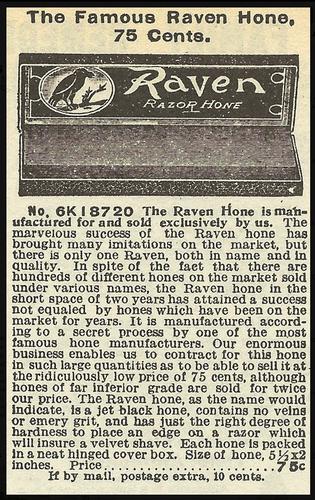

The Raven hone was one of the main sold Barber Hones within a certain period in the Sears and Roebuck catalogue, it was sold within the other well known Barber Hone like (Swatys, Nox All, Swatiska, Barbers Pet, Apart, etc.).

The original Price the Hone was sold was always between 0,65 - 0,75 as far as i checked my documents they sold it from the beginning of Spring 1907 up to Spring 1925, didnt checked the newer catalogues up to date....so could be that later on other newer versions were sold. The wrote in their advertisement that they sold it "exclusively"...

So nothing to add in Perfomance here, because i do not own the stone, but a bit on History out of the Sears & Roebuck Catalogue....Last edited by doorsch; 09-03-2014 at 11:07 AM.

███▓▒░░.RAZORLOVESTONES.░░▒▓███

-

The Following 3 Users Say Thank You to doorsch For This Useful Post:

Hirlau (09-03-2014), Leatherstockiings (09-03-2014), tedh75 (09-03-2014)

-

09-03-2014, 04:08 PM #9Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

Sears only sold the hone, they did not make it, as witness this ad from the Sears 1908 Catalogue:

It says 'made for us', probably by one of the few specialist barber hone companies like the American Hone Co. who made Frictionites and other hones and specialised in making hones for other companies to re-sell.

I have had one as related above and if I recall correctly it was an equivalent of about 10k or so.

Regards,

Neil

-

-

09-03-2014, 04:27 PM #10

+1 a hundred times! I've been saying for a long time that Barber Hones, MOST, not necessarily all, should not be lapped unless it is in such poor shape that there is no way around it. Lapping will inevitably change the performance and effect of how the hone (Most not all) was originally manufactured to perform. As Neil notes, especially the cold pressed/set hones.

I have (sadly or happily depending on your perspective...LOL!) probably 150+ Barber Hones collected over many years. Many of the original instruction sheets advise against refreshing or lapping the surface, as this will destroy or CHANGE the honing surface as designed. Some advise against exposure to heat or hot water; sunlight; caustic soaps, etc. because of their degrading effects on the hone.

Some hones...such as the well regarded Frictionite '00' ( a 'Hot' Hone, and my personal Favorite!)) actually call for the surface to be refreshed with light lapping whenever there is a build up or discoloration of the surface. A rub stone for this purpose was even included with the hone when purchased new.

Also...I don't think I have ever found a Barber Hone that was in decent condition that needed to be 'Lapped' in order to 'flatten or true up the surface'. Think about it...most Barber hones were used to simply refresh a slightly dulled edge, instructing the user to only do anywhere from 2-5 or up to 10 "VERY LIGHT and SOFT STROKES". If you did this for 3-5 strokes a week for a year, your only talking about maybe 250 LIGHT STROKES on the hone. Not enough IMHO to change the performance of the honing surface as it was designed and manufactured to be.

Sorry for the off topic rant.... ... so just to be more in line with the OP's post, I also have a 'Raven', but sadly, I have never tried it out so I cannot accurately report on it's effectiveness. I can say, however, the instructions of the 'RAVEN' says that when the surface needs to be cleaned it should be cleaned only with a light rubbing with emery cloth. That or a toothbrush as Hirlau suggests. Also, that it is a nice looking hone.

... so just to be more in line with the OP's post, I also have a 'Raven', but sadly, I have never tried it out so I cannot accurately report on it's effectiveness. I can say, however, the instructions of the 'RAVEN' says that when the surface needs to be cleaned it should be cleaned only with a light rubbing with emery cloth. That or a toothbrush as Hirlau suggests. Also, that it is a nice looking hone.

WP34Last edited by Wolfpack34; 09-03-2014 at 04:38 PM.

Lupus Cohors - Appellant Mors !

-

The Following 4 Users Say Thank You to Wolfpack34 For This Useful Post:

doorsch (09-04-2014), Hirlau (09-03-2014), Neil Miller (09-03-2014), tedh75 (09-03-2014)

25Likes

25Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote