Results 1 to 10 of 23

Thread: Messing With A Mystery

-

12-20-2014, 10:32 AM #1

Messing With A Mystery

Messing With A Mystery

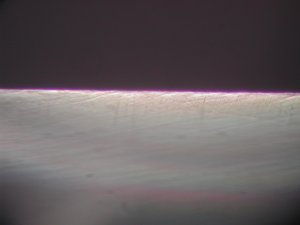

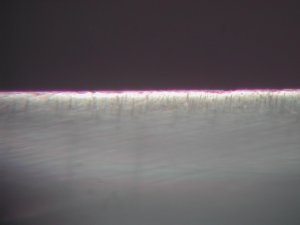

There isn't any questions here just me ranting about my mystery hone. Everytime I think I am getting closer to figuring this thing out it goes in a completely different direction. The stone is quite soft, but fine. At times it seems to work fast and others slow. Anyway I honed up two razors up to my Norton 8k and decided to use the mystery stone and see what it does. I only use this stone with water or lather, but never slurry. Seems like lather or soap really slows it down, but it varies alot from razor to razor. It doesn't seem to respond well to slurry. Well one razor after 10 laps it improved the Norton 8k edge significantly. The other razor took about 30 laps to achieve the same thing, but the edge on both razors started to look like the first photo and it works up to looking like the second photo the more laps you do. Photos were borrowed from the library. The edge really seems to degrade fast the more you do. This is all with no pressure laps. I know different razors have different hardness so will react differently to the stone. The stone seems to work well to touch up a razor, but finishing on it can be a PITA. Seems like it can take a completely shave ready 8k edge and improve it significantly and other times just degrade the edge so fast. I have been only doing 5-10 laps at a time and 10 laps is really pushing the boundary at one time.

-

12-20-2014, 12:44 PM #2

It looks like a strange stone.

What do you mean "It doesn't seem to respond well to slurry"? It doesn't cut fast, is it too coarse, or the results are not consistent?

I unfortunately don't have a clear image on my mind about stones that, initially improve the edge but with a few more laps and they then degrade it. If you asked the same thing five years ago, the answer would be "it's overhoning", but I doubt that's the case here.

Could it be that it's a very fine stone, but it has few, very small inclusions? For 10 laps, the damage from the inclusions would be minimal, offering a better edge than the Norton. But with more laps, the damage from the inclusions would be severe enough to ruin an excellent edge.

I don't know how long you have the stone, but if it's relatively new for you, I would suggest you to lap it again, diamond plate, sandpaper, whatever you have, with a progression until the surface is smooth, wash it thoroughly, and test it again.

I would also suggest you to "study" the slurry, the answer could be there.

About the razors now, yes, they do tend to respond differently on the same stone, but unless you are comparing stainless with high carbon, or a real razor with something like a gold dollar, the differences should not be too obvious.

And, yes, both lather and oil make almost all fine stones slower compared to clear water.

In any case, should you continue to investigate the mystery of the mystery hone, good luck.

-

The Following User Says Thank You to Vasilis For This Useful Post:

JSmith1983 (12-21-2014)

-

12-20-2014, 01:45 PM #3Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,451

Thanked: 4829

Due to my rockhounding habit I have honed on a lot of strange rock. Sometimes that is just the way it goes with an aggressive cutter in the rock. It is also possible that the abrasive comes loose easily and the hone is actually better as a pre polisher. I do agree that it may take you some time to figure this one out. I sent a hone to a guy in Kansas once that has a lot of experience. He was quite challenged by it and in the end really liked the hone. You may find the same thing with this one. Some hones will give us clear signs on when to stop and others will let us fly past our mark and never say a word. It may be that when to stop is the key with this hone. Good luck and let us know if you solve the mystery.

It's not what you know, it's who you take fishing!

-

The Following User Says Thank You to RezDog For This Useful Post:

JSmith1983 (12-21-2014)

-

12-20-2014, 03:07 PM #4Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

I think this seems to be much more common on fast cutting stones. Here's my theory: The stones like this cut very fast, and improve the existing edge as you hone by thinning it down but not really forming a new apex. Once you get to the point where a new apex is being formed rather than the existing one thinned, the aggressive cutting action of the stone is making the edge a little ragged (on a microscopic level of course). When using this stone the edge either needs to be frequently checked to see where it begins to degrade as you hone or only used as a prefinisher.

-

The Following User Says Thank You to eKretz For This Useful Post:

JSmith1983 (12-21-2014)

-

12-20-2014, 03:53 PM #5

The slurry really degrades the edge even faster. I have been experimenting with this stone for awhile now off and on. As for inclusions I have no clue. None to the naked eye. Don't feel any when honing. It will take awhile before I can fine tune it. I just wish it wasn't so soft.

Last edited by JSmith1983; 12-20-2014 at 03:56 PM.

-

12-20-2014, 07:19 PM #6Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

That makes sense, since slurry speeds up the abrasive action on pretty much every hone I've ever seen. Does the stone self-slurry? I have had some small success by using a rubbing stone to smooth the surface of an aggressive stone some and take down the aggressiveness a few notches. This only works for a very short time with a soft stone though, as they will shed abrasive particles readily and quickly default to their natural texture.

Use the rubbing stone dry, then rinse and wipe/wash any remaining slurry off the stone. Hone with as little pressure as you can manage on straight water and stop immediately and repeat the dry rub/wash if the stone starts to self slurry.

Really this is just a workaround if you don't have a better stone to use, I found that it works just by playing around with a LOT of stones for a LOT of hours, lol.

-

The Following User Says Thank You to eKretz For This Useful Post:

JSmith1983 (12-21-2014)

-

12-20-2014, 07:37 PM #7

Your hone acts much like the better barber hones. Many were to be used dry and wiped with a damp cloth. They were also used with very few strokes to refresh a blade rather than to reset it.

so the continuing information posted above is quite valid. I have a few natural stones which behave the same way. I can use them wet or dry and get differing results. The ones at my sink side are used dry to refresh edges that are not quite there.

Have fun in the learning!!

~RichardBe yourself; everyone else is already taken.

- Oscar Wilde

-

The Following User Says Thank You to Geezer For This Useful Post:

JSmith1983 (12-21-2014)

-

12-21-2014, 02:41 AM #8

I think Richard's on to something with the barber hone idea.

Let's assume the stone is coarser than the previous stone you used. 10 laps is not going to remove much metal at razor finishing pressure, and may produce a better feeling edge regardless of the slightly coarser grit. A harder razor takes longer to degrade, but all will if you spend enough time on it.

Just some thoughts.

Cheers, Steve

-

The Following User Says Thank You to Steve56 For This Useful Post:

JSmith1983 (12-21-2014)

-

12-21-2014, 10:00 AM #9

Well thought I would mess around with the stone again when I found a razor in my todo box. It was one of the first razor that I honed. I remember it took a fantastic edge and that it was really fast to hone from butter knife dull to shave ready. I remember using it to test out my newly acquired Jnat that I got awhile ago. Not sure why I put it off to the side instead of using it, but after looking at it I noticed the washers are upside down and have that sharp look to them and about only 3/4 of the razor is honed. The heel slants upward at an angle. Maybe that is why it was so easy to hone and why I put it to the side. Anyway figured I would see what the stone would do the the hazy finish left from my Jnat. Well after about 100 laps dry and 100 laps wet it did absolutely nothing to the finish or the edge. Also noticed that the heel where it slants can't be honed without lifting the toe off the stone really far and the angle of the bevel if done that way would be about 45 degree so that isn't getting honed. Don't think it would have left the factory that way so I'm guessing it got chipped and someone removed it. I don't remember doing it. Anyway I think I am going to give up on trying to figure this stone out for awhile and just use it occasionally to touch up a razor and see how that goes. I need to pay more attention to my todo boxes.

-

12-21-2014, 10:49 AM #10Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

When following a JNat with another very fine stone it can be difficult to see the result as the JNat leaves a microscopically pitted surface, so until almost all of those pits are gone it really doesn't look like much is happening to the finish unless you have pretty high magnification. Best way to test new finishing stones in my experience is to take them up to 10k or 12k via synthetic progression then go to your test stone. This way you have a very smooth uniform finish/edge to start with and any change to the finish or edge caused by the test stone will be very evident.

-

The Following User Says Thank You to eKretz For This Useful Post:

JSmith1983 (12-21-2014)

18Likes

18Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote