Results 1 to 10 of 21

Thread: Bavarian-Frankonian Hones

Hybrid View

-

12-29-2014, 01:44 PM #1

Bavarian-Frankonian Hones

Bavarian-Frankonian Hones

Just had a little time today so i wanted to share my "personal" findings or "experiences" i had so far with Peters "Bavarian-Frankonian Hone".

As its my personal statement it might be different from what Peter did experience...

The most interesting talking about the properties of these stones is that they have a very wide range they can be used...setting a razors Bevel with a 1k stone its easily possible to grab the Bavarian Stone and use it afterwards till the Bevel is finished...

It can be compared to the properties which coticules give when they are used with a thick slurry and working the bevel further more to a finish with water f.ex. Dillocut...

The difference in the End is that the Bavarian-Frankonian gives a very smooth shave, probably a bit smoother then i experienced with fine Thuringian Stones. I have to admit the the Edge these stones give, compared in smoothness to a Thuri are different! I cant explain it myself but you can seriuosly feel that the edge wasnt finished with a Thuri...a fact i firstly didnt realized that much personally, but my girlfriend (yeah she uses a straight on her legs) did feel a difference with two straights i gave her. One was finished with a Thuri the other with the Bavarian-Frankonian...so it seems not be only my feeling...

So lets show some more pictures, this is a 5/8 Wade & Butcher Special "Sheffield Steel" i used to experiment a bit past the last two months and i have two rubbers i use on the Bavarian-Frankonian, one is a red Jnat which is much softer and a UK very Hard Slate stone which is harder then Peters Stone...

i dont think that any of the rubbers give a relevant use to the slurry itself, especially the Jnat, but its a good color Indicator to see how metall is removed...the slate is very hard it only creates slurry from the Bavarian-Frankonian.

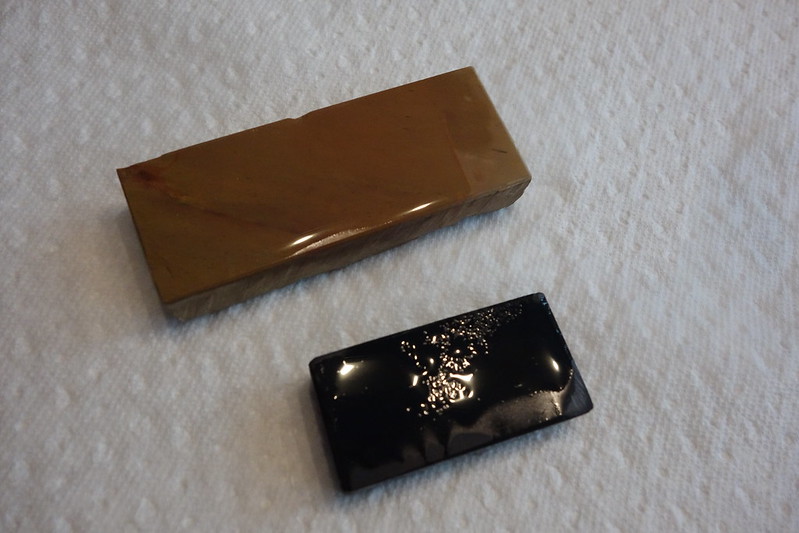

The first pictures show the slurry created with both stones after 20 laps, the stone in combination with a thick slurry is a fast cutter which sounds very coarse (you can hear it also from the sounding when honing, especially on thinner grinds)....

Jnat rubber, 20 Laps with pressure:

Hard Slate rubber, 20 Laps with Pressure:

Futher more after 40 laps with less pressure:

So you can see the stones work very fast! I prefer to dillute the slurry several times until i wash of the stone and proceed with plain water...

Interesting is that it seems when using a thick slurry on the stone and doing several laps (50-80) i had the feeling that the slurry changes a bit in thinking of its working capacy...it seemed working slower after some time...probably a usual behavior i dont know...

The Bevel in its optical appearance is less shiny then honed on a Thuri, it also seems that the stones are a bit lower in grit, but thats just my feeling and doesnt effect the result in shaving.

So these are my findings!

I really like the stones in their appearance and in their working properties and i well appreciate Peters Research here! This is one of my personal "Keepers" and its beside my Thuri Bouts, some Cotis and two Special Stones one of my most Interesting stones i have...

Thanks Peter!Last edited by doorsch; 12-30-2014 at 01:04 PM.

███▓▒░░.RAZORLOVESTONES.░░▒▓███

-

-

12-29-2014, 02:31 PM #2illegitimum non carborundum

- Join Date

- Jan 2008

- Location

- Rochester, MN

- Posts

- 11,552

- Blog Entries

- 1

Thanked: 3795

OK the more I read this the more I want to play with one.

Jimmy I might be willing to sell your Frankonian back to you!

60Likes

60Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote