Results 1 to 9 of 9

Threaded View

-

02-05-2015, 11:35 AM #1

Ding'd Shapton Glass 4k.. best approach for the resulting chip...

Ding'd Shapton Glass 4k.. best approach for the resulting chip...

Not sure how it happened. I think the protective box I made.. didn't.

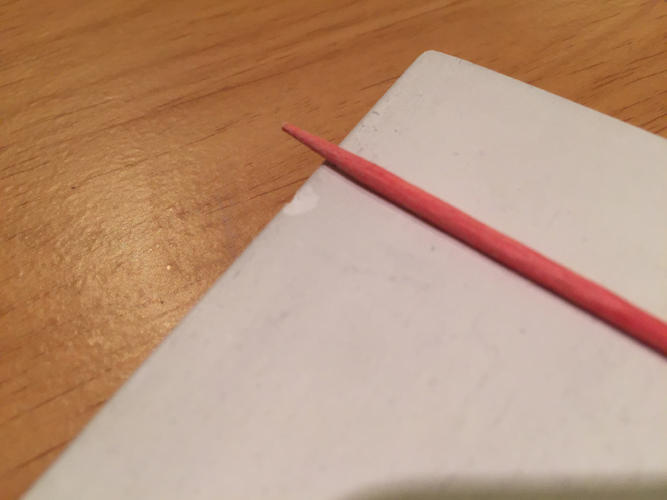

I have a small chip out of the long edge of my SG 4k. It's definitely in the when on my 'to' stroke if it's positioned on the right side. Less so, if I put on the left side as pictured.

Only option I can think of is to smooth the rough edges with.. hand sanding with paper around a dowel? Dremel?

Any other suggestions?

Pictured next to a wooden toothpick..

Last edited by MikekiM; 02-05-2015 at 11:40 AM.

5Likes

5Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote