Results 1 to 10 of 22

Threaded View

-

03-09-2015, 08:11 PM #1Senior Member

- Join Date

- Sep 2014

- Location

- Riyadh, Saudi Arabia

- Posts

- 151

Thanked: 66 Translucents Arkansas One Stone Honing !!!

Translucents Arkansas One Stone Honing !!!

Hello everybody,

I have been for along time silent viewer of SRP and B&B, and I really appreciated the knowledge that you guys provide in this forum...so I hope that you accept my first post here.

I don't know if this is new or I'm repeating someone's discovery, anyway while I'm playing with my vintage Translucent Arkansas the other day I tried a small pocket Hard Arkansas stone to produce a slurry on the Translucent Arkansas... which did yield a good amount of slurry and accelerated the stone speed 10 times at least...

Then I started to experiment with different types of slurry from different stones Eschers, Coticule, BBW Cnat and whatever else I had.

The results were astonishing, I was able to get better edges from all the stones using their slurry on the Translucent Arkansas Hone.

I can set the bevel on a razor and take it up to shave ready using Coticule slurry in half the time that I take using Coticule stone, no dilution of slurry or nothing, I try only to maintain the slurry from drying out by adding water as needed.

The most beautiful thing about this method is it really helps to know which stone is finer than the other.... now I know which of my Coticules is finer, I also found that a vintage BBW that a had is finer than some of my Coticules, I also divorced that one of my Coticule slurry stones (recently mined) is as fine as an Escher hone.

Even it does help with the Eschers where is really hard to spots the difference between them since they are all have a consistent quality, I did find that the finest Escher hone that I have is a blue green one.

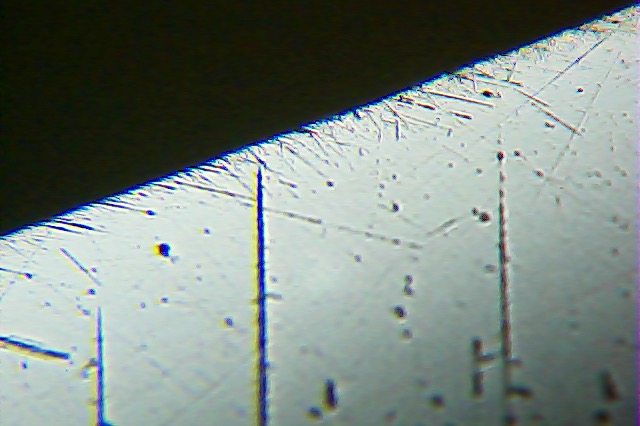

The results using this method are very consistent, even under the microscope which help me a lot in comparing the edges.

The method is very simple

1. I spray water on the Translucent Arkansas the I rub the selected stone to produce slurry.

2. I starts with fair amount of pressure if I want to set the bevel, moderate pressure if I want to remove micro chips, or light pressure for touch up .

3.after I finish I spray water on the Translucent Arkansas then I brush it with a small brush that I got from Beauty Supplies Shop finally I wipe the stone.

I tried to produce slurry using Hard True Arkansas, but without any luck the stone is to hard

I have a microscope but the photo quality of it camara is very poor thats way i didn't post comparison pics

( x160 )

I know that this method is not orthodox by any means , but it does a very good job.... also you can use a lot of pressure without harming the hone while setting the bevel, but you need to be aware that you might miss up the razors grind.

I hope this does help someone to see new potentials for their Translucent Arkansas.

Thanks for everyone, and sorry for my bad English

-

The Following User Says Thank You to AljuwaiedAK For This Useful Post:

Steel (05-28-2015)

28Likes

28Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote