Results 1 to 5 of 5

Thread: Carborundum 79 Dry Hone

-

06-08-2015, 06:03 PM #1illegitimum non carborundum

- Join Date

- Jan 2008

- Location

- Rochester, MN

- Posts

- 11,552

- Blog Entries

- 1

Thanked: 3795 Carborundum 79 Dry Hone

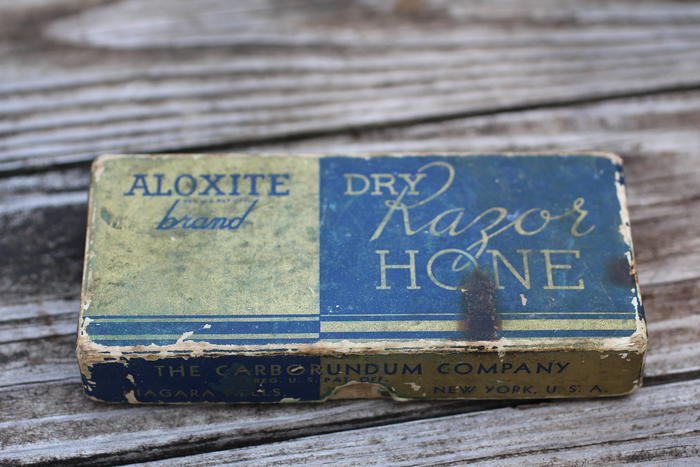

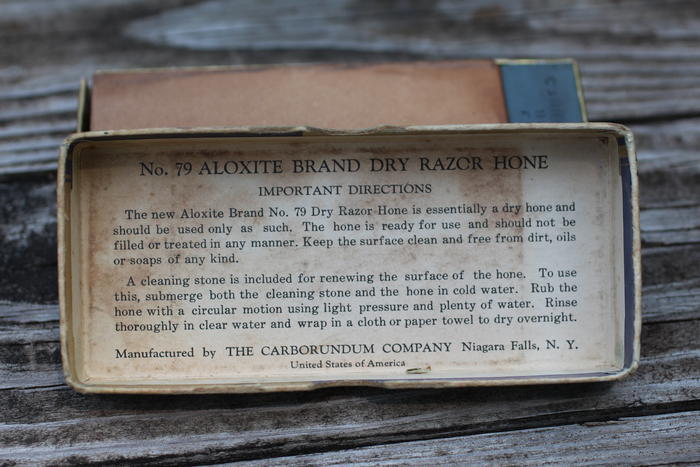

Carborundum 79 Dry Hone

A member here wanted info and photos about the rubbing stone for the Carborundum Aloxite 79 dry hone. I would say that the rubbing stone is most similar to a Carborundum 106, which is porous and so unlike the other lower series 100 hones. He wanted photos so here they are.

-

06-08-2015, 06:09 PM #2illegitimum non carborundum

- Join Date

- Jan 2008

- Location

- Rochester, MN

- Posts

- 11,552

- Blog Entries

- 1

Thanked: 3795

And the rest...

-

06-08-2015, 06:40 PM #3

Thanks for the info Ron

I also see the rubbing stone's label as FF-G7.

Assuming the Carborundum Co follows their own established grit sizes of 120, 140, 150, 160, 170, 180, F, FF, and FFF

Then it would stand to reason the grit of the rubbing stone to be approx 320-400 grit.

Sound right? Most cleaning stones are much more course than the hone they are used on.

DaveLast edited by dta116; 06-08-2015 at 06:48 PM.

-

06-08-2015, 08:12 PM #4illegitimum non carborundum

- Join Date

- Jan 2008

- Location

- Rochester, MN

- Posts

- 11,552

- Blog Entries

- 1

Thanked: 3795

I suppose that is right, but I still hesitate to assign a grit rating to any synthetic hone. Barber hones used up to 4F but their effect on blades was a result, at least, of the right combination of grit size, density, and binder.

In this case, I really think that you can use any natural stone or a harder synthetic, like virtually any other barber hone, to clean the Aloxite 79. If you follow the directions for cleaning and submerge both hone and rubber while rubbing them together, the yellow hone is quickly cleaned and the water turns yellow. This is because the hone is much softer than the rubber. At least in this case I think the grit rating of the rubber is irrelevant for effectively cleaning the hone.

-

06-08-2015, 09:33 PM #5

Thanks for adding !!

███▓▒░░.RAZORLOVESTONES.░░▒▓███

4Likes

4Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote