Results 11 to 15 of 15

Thread: Maruka Hatanaka Nakayama

-

06-23-2015, 11:13 PM #11Senior Member

- Join Date

- Sep 2014

- Location

- Riyadh, Saudi Arabia

- Posts

- 151

Thanked: 66

-

06-24-2015, 09:11 PM #12Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

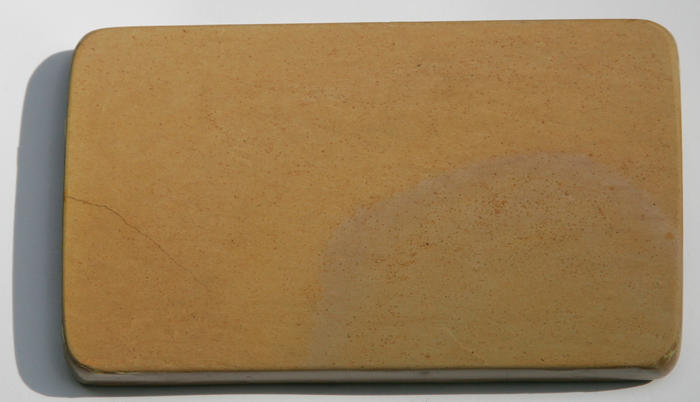

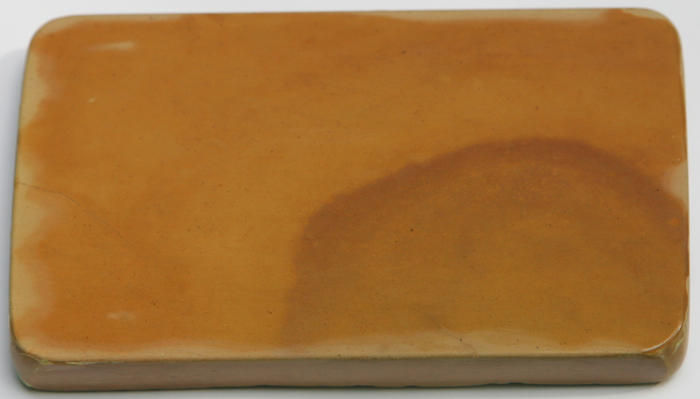

Here are a couple shots of it. A friend of mine traded it to me for one of my Kuro slate "found" stones - he said the stamps were removed when he rounded the sides and edges - he does this to all his stones. More money than sense IMO (he doesn't use computers, no danger of him reading this, lol). I don't really care though anyway, as the stone is so good that I will never ever sell it. Super fast cutter but still gives an amazingly fine and comfortable edge. I normally finish on a very light slurry with this one. One of my very favorite stones. Color is corrected and bang on.

-

06-25-2015, 08:53 AM #13Senior Member

- Join Date

- Sep 2014

- Location

- Riyadh, Saudi Arabia

- Posts

- 151

Thanked: 66

I remember reading in one of Iwasaki books the he recommend sanding out the saw marks on the sides of the stone and removing the skin to protect the blade during honing.

So I think you can find a lot of super Jnats without id maybe for this reason.

Thanks for sharing this s amazing stone.

-

06-25-2015, 09:01 AM #14

Maruka Hatanaka Nakayama

Maruka Hatanaka Nakayama

Could be a way! but you would do it today if you believe 100% you keep the stone your lifetime, otherwise you would lower the price of the stone removing the stamp....

And if youre careful "normally" you do not hit either the Kawa nor the sawmarks if you have a chamfering....

Removing the Kawa would it make sense too see how the "other" side of the stone works ?!?███▓▒░░.RAZORLOVESTONES.░░▒▓███

-

06-25-2015, 09:15 AM #15Senior Member

- Join Date

- Sep 2014

- Location

- Riyadh, Saudi Arabia

- Posts

- 151

Thanked: 66

Totally agree with you losing the hone id will lower the value significantly, I would rather keep it and adjust my way of honing instead.

Here is the quote from Iwasaki book:

Just like your Nagura, carefully round off the corners. Flatten the sawmarks on the sides of the hone

with sandpaper. There are stones with purple or brown “skin”. Remove this completely. This skin is

harder than steel, and so any fragments of it can cause serious damage to your edge. It is also best to

smooth and even out the uneven areas of the bottom of the hone. In the past, people often coated the

sides and bottom with Urushi lacquer, but these days “Hone Coat” is sufficient, and it dries quickly.

11Likes

11Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote