Results 1 to 9 of 9

14Likes

14Likes

Thread: Charnley Forest steel types

-

09-30-2016, 07:37 PM #1Senior Member

- Join Date

- Jan 2015

- Location

- Apex NC

- Posts

- 535

Thanked: 90 Charnley Forest steel types

Charnley Forest steel types

So my buddy was asking me if a charnley forest stone would cut A2 and other powder steels? He is a knife and woodworking guy. I don't know much about steel types so figured someone here may be able to educate me on the answer to this.

-

10-01-2016, 07:40 PM #2

A2 yes since it's only a high carbon steel.

Powdered steels it depends. It almost feels like a baited question because steel alloys in so many ways, and a few adjustments in the forging process can create steels with very different properties.

Carbon steel at <60 rockwell hardness then the CF should be able to deal with it.

Carbide steel with a >60 rockwell hardness you may find the silica just can't do anything to the metal. It depends on what they have alloyed into the steel, and how much free carbon was available, And what temps the metal was forged at. Vanadium 15V steels when made and hardened correctly can have a hardness of over 80 rockwell. You'd need something far harder than silica to abrade that, like silicon carbide, CBN, or diamonds. It's variable because when the correct forge conditions are not met you can still have a steel with the correct vanadium content, but the free carbon did not react and form carbides.... So the metal content is there but it's not a carbide steel.

Tools and knives are often made in non-carbide steels. The added alloy metals are there for other properties like corrosion resistance, or to improve toughness. A knife that is too hard to sharpen, and brittle is no good in a lot of applications. There are exceptions to this, and some very brittle but also very hard steels are used for cutting, but generally this is expected when you are cutting equally hard materials like other metals and you can control impact so as not to damage your carbide steel cutting faces.

The only real way to know what will sharpen what when exotic alloys are used is to ask the manufacturer. If there hardening beyond 60, and using something exotic to sharpen on, then CF probably won't work. On the other hand if there using water stones to sharpen with aluminium oxide abrasives then CF may well work.Real name, Blake

-

The Following User Says Thank You to Iceni For This Useful Post:

rideon66 (10-02-2016)

-

10-01-2016, 07:55 PM #3The First Cut is the Deepest!

- Join Date

- Feb 2010

- Location

- Upper Middle Slobovia NY

- Posts

- 2,737

Thanked: 481

Pretty much the prior information is correct. BUT... keep in mind that a CF stone is not really for cutting steel. its use with razors is really best suited to final polishing. Which it will do an admirable job on. There are very few razors out there with a hardness over 60-62 A good noviculite stone will work well imo.

I have had excellent results on my Brian Brown razor, which I am under the impression to be in the 60+ range.

-

10-01-2016, 09:26 PM #4

The Charnley forest stone will work on A2 steel even if correctly hardened, but don't expect to use an 1k stone or sandpaper, jump on the Charnley and expect it to work. But it will abrade steel.

Iceni, there is no steel that reaches 80 RC hardness.

https://www.crucible.com/eselector/p...s/cpm15vp.html It's optimal RC hardness is at about 63.

There is a difference between "Vanadium carbide is 80RC hard" and "steel is 80RC hard". Ceramic knives have a lower RC hardness value.

The presence of "exotic" carbides in steel don't change it's hardness but other characteristics, wear resistance for this case. A Charnley won't be able to abrade that steel but not because of its hardness, it will be because of it's wear resistance. And because Vanadium carbides are a pain in general. No matter what you do, you can't achieve the hardness above 67RC on any steel, quenched in water, and around 65RC quenched in oil. There is no steel that can harden up to 80RC.

There are the famous Iwasaki tamahagane kamisori, I don't know what they did but they managed to achieve that 65-67RC hardness. At that point, no natural stone can wear them, not Japanese stones, no coticules, you have to use synthetic stones, or wear your naturals a lot more compared to a classic western made razor, to see a small difference.

-

10-02-2016, 03:02 AM #5I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

-

10-02-2016, 03:48 AM #6I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

A follow up, I refreshed my Iwasaki Tamahagane on a J-Nat and it worked very well. I remember that initial bevel set up was a bit challenging but now that the bevel is set the razor is easy to handle. I will add that there were other Japanese razors that I have honed that were tougher to get right on Jnats compared to the Iwasaki.

Stefan

-

10-02-2016, 04:14 AM #7

I named the Iwasaki tamahagane because it's the most easily recognizable. And probably most expensive. I was referring to classic razors, not kamisori, I assume you are referring to that type too. The image I've had in mind is the classic extremely hard Japanese razor. Thinking about it, harder steel generally means that it needs less frequent honing, with its high hardness the edge lasts longer. A trade-off, it's hard to hone, but it needs honing less frequently.

You can touch-up them, but the ones that are in the 65-67RC range are a lot more challenging than the ones around 60 or a bit below. Saying that the stone stops working I mean it gets a lot slower and honing them is less enjoyable, not that it doesn't work at all. I've had an interesting conversation with Peter about Iwasaki tamahagane and coticule stones, where he noticed that coticule stones are getting really slow on them.

For the Japanese stones, from what I have seen, opinions are split, many seasoned users find that they work on 60+RC tool steel, and many others believe that steels hardened above 60, especially if they contain carbide forming elements are above their capabilities. I guess I agree with the first group.

Anyway, these tougher razors you mention are the ones I have in mind, where you can see that the stone gets many times slower on them.Last edited by Vasilis; 10-02-2016 at 05:05 AM.

-

10-02-2016, 11:15 AM #8

The problem isn't any of our interpretations it's how we measure things.

There is no industry standard for describing wear resistance. Rockwell hardness is often used because as a figure it describes fairly accurately what you will need to abrade something along with the Mohs scale.. However it doesn't always describe all aspects of how a material is behaving.

Carbide steel is indeed 50-60 RWH for an indent test, But it can behave like a material up to 80+ RWH for abrasion resistance. The question here was about abrasion resistance. Scratch hardness is more of an indicator, but again that test fails for Carbide steels as the unique make up of the material means a scratch test will have a varied response, You can take an average, or the extremes of that hardness. When it comes to actually abrading it the harder elements will cause the material to act far for more resiliently, And it's that resilience you need to quantify. Provided you know you are talking about abrasion resistance then using the carbide RWH to describe carbide steel is perfectly fine.

It's much like looking at a diamond plate.

If we were to put a centre punch on it and look for an indent test it would prove to be soft.

If we were to look at the diamonds then it would prove to be very hard.

Because we are only interested in the abrasion resistance and we know that the diamond coverage is sufficient to protect the backing we can use the diamond hardness values to describe the wear resistance.

There is more to hardness than just a RWC test. I used <60RWH for a reason. You can make steel harder than that. The mechanical properties for such steel would fall outside of the rules used for A2 steel. As such you need to know what that steel is, and what is forming in it to be able to use the RWC value for abrasion resistance. I see you have diverged into an exotic steel and within 1 post you have no idea what you are actually dealing with. This by it's nature is the problem when dealing with exotics. You have to have the charts and the basic information to know what you have is what you have..... You also need to know the whole process for the production for that steel from annealing to hardening, and in some cases final finishing as well. As some off the harder steels will loose RWH when exposed to moderate temps from things like grinding, Or need very fine control to gain the desired hardness.

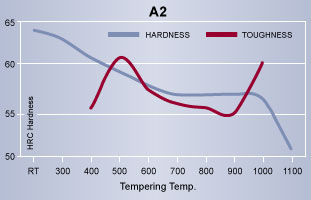

A2 toughness/hardness charts show this pretty well. It's only for 1 type of steel but there are other charts for other steel grades. You can clearly see the point where you want to harden to. Where toughness and hardness are compromised to give the best overall characteristics.

High Speed Steel | A2 Tool Steel | A2 Knife Steel

If you can not control the process, and hit the exact values for the steel at every critical stage then there is no way to prove other than a destructive test that a finished product is indeed the RWC value you are claiming. You can make an estimate, and you can do a run of tests, even 1 per batch. The final value of what you get sold however is always an estimate.Real name, Blake

-

10-02-2016, 07:59 PM #9I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote