Results 31 to 40 of 41

-

11-09-2016, 02:54 PM #31

I cannot see the point of doing this at all. It is obvious that smaller stones can be used to hone razors, they are what I use for the most part. But to attempt to cut a perfectly good 8" x 3" stone just to meet a hypothetical ideal makes no sense to me. Without meaning to offend, I think that you are tilting at windmills here.

"Every normal man must be tempted at times to spit on his hands, hoist the black flag, and begin to slit throats." -H. L. Mencken

-

11-09-2016, 06:50 PM #32Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

"I'm not really following you here. My original premise was that if an 8" x 3" honing surface suffices for an 8" knife, then perhaps a 4" x 1-1/2" honing surface would suffice for a razor. I still maintain this, so my premise hasn't changed."

The point is, sharpening a knife, has nothing to do with honing a razor… So everything after that, does not matter.

A new guy learning to hone is processing a lot of information. One of the most important things is keeping the razor, edge and spine flat on the hone.

Using a smaller/narrower hone, increases the difficulty, with no-added benefit. I refer to your post 28, where you describe your process of learning to hone and all the stones you experimented with, when all you needed was an inexpensive 1K, and a 3/8 or 4/8 K, combo Naniwia or Norton. Once “Mastered” then experiment.

“Yet here the problem remains that there are not many synthetic water-stones cut to these format sizes.”

There is a reason for that… There is no benefit?

“At the time, in starting out, I was thinking that a narrow stone would help with a wonky bevel, seemingly dismissed by folks, both here and elsewhere.”

Using narrow stones to hone, compensate for improper technique, it may work but is unnecessary. Just learn the rolling X stroke.

So, your original premise, “This leads me to conclude that if an 8" x 3" honing surface suffices for an 8" knife, then perhaps a 4" x 1-1/2" honing surface would be more than enough for the razor, which is essentially a folding pocket knife in this regard. Does this seem reasonable?”

Nope…

-

11-09-2016, 10:33 PM #33

This thread got me thinking an looking around my desk. The smallest hone there is a Norton #37280K9. I don't know what grit 3/8" x 3/8" x4" I sharpened my leatherman and it worked ok. I held the knife still and moved the hone though. My lansky set that I like for pocket knifes is 1/2" wide by 4" long with lots of plastic on top to protect my fingers. Which makes me think about the 2 sided diamond plate that I carry in my day bag. 2" x 3" but only 1/4 of an inch thick. Small and nice to carry but I would not use it held in my hand or I am afraid I would loose my finger tips! I have big but not what I would consider large hands and a full size 4000/8000 Norton feels good holding it in my hand while honing.

-

11-10-2016, 10:43 AM #34

I don't quite understand all the fuss about the OP's question (although I agree that the wording may have been a bit confusing at times), it seems like a valid question. After all, aren't most synthetic hones designed with knife sharpening in mind?

In short, yes, small hones (4"x1-1 1/2") will suffice for razors. And yes, they are beneficial if you prefer to do your honing handheld. However, cutting a hone to size seems like quite the hassle to me, but if you insist on handheld honing on a synthetic, I could understand. If handheld honing is not a must for you then a large hone is fine too.

I do prefer slightly smaller and thinner hones over large ones, as I hone exclusively with the stone in hand. That being said, my favourite hone is about 3"x4". But about 1/2" thick.

-

The Following User Says Thank You to Pithor For This Useful Post:

Brontosaurus (11-10-2016)

-

11-10-2016, 01:42 PM #35Junior Member

- Join Date

- Mar 2016

- Posts

- 26

Thanked: 16

I would like to introduce a new element to this discussion : shape.

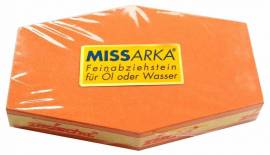

This is the only commercial hexagonal stone i know, from what i guess it's a traditional shape and size for razors and other small blades. It's 3,2 inch wide in the middle and tapers to 2 inch on the ends and it is 4,8 inch long. There are vintage stones available sometimes on Ebay (here in germany at least) that are hexagonal, always slates. The shape and size makes it perfect to hold it in the palm of your hand and do the rolling X pattern, so i prefer it for smiling razors. Even among the razor community it is not a very popular stone, although it's a german produced stone. Here in germany the Naniwas and Shaptons have cornered the market, at least they are the most recommended stones. The stone is rated F1000 (~ J3000) but the scratch pattern suggests it to be more like a J4000. I like to use it with lather and then continue directly to my finisher.

I like small stones, but usually i go to my Naniwa combination stones first. I have a Fällkniven CC4 as a travelling stone, conditioned to 8K on the black side and >12K on the white side, the Fällkniven is sized 4 x 1,2 inch. And i have used a 3 x 1 inch ceramic stone that has the same ceramic material as the Fällkniven (a chinese knock off to the DC3), and it is acceptable as a travelling stone too (if you refrain from using the diamond plated side, estimatedly 300 grid).Last edited by hein31; 11-10-2016 at 01:54 PM.

-

11-10-2016, 03:12 PM #36

You bring up an interesting point about the watching the fingertips with hand-holding. At one point, 2-3 years ago, I was using a DMT 6" x 2" perforated surface diamond hone hand-held for dealing with a beater razor as received with chips. As the diamond hone was fairly thick, around 5/8"-3/4", I thought I could grip it on the sides. As bringing a fingertip up to the surface would a problem, I tried to avoid this; but at one point one fingertip did slip above do oversight and I received a nasty cut as a result. Nothing serious in the end, but it taught me to always hone on the palm with the hand and fingers completely outstretched.

Most of the time the thickness of the stone (e.g., around 1/2" to 3/4") is enough just to rest it on the hand. But with thinner stones at 1/4", as you mention, thinness would be a problem. To circumvent this, I have glued them onto wooden blocks cut to the same approximate surface dimensions to effectively raise the stone up a bit. (A two sided diamond hone is a special case, though. One could cut a similar sized block and then create a shallow hollow with a Forstner bit and a chisel on one surface to lodge the hone and raise it up partially from the block. Simply ining the block's surface with a glued piece of rubber should also work.) Similarly, if I have two stones of the same surface dimension size which are 1/4", I might glue them together with A/B silicone in between to create a 1/2" thick combo stone that way.Last edited by Brontosaurus; 11-10-2016 at 11:29 PM. Reason: add missing word.

Striving to be brief, I become obscure. --Horace

-

11-10-2016, 03:23 PM #37

Thank you for your appreciation of my original question. As for cutting being a hassle, I have sometimes searched for natural stones in the field and used a dedicated tile-cutter to cut these down to different formats. And using it to cut synthetic stones is fairly quick and easy. Only hassle there is in cleaning up the tile-cutter afterwards. One can also use a hacksaw to cut synthetics down, but there is less control that way, and is does take a little while by hand. But it is doable and does not make a big mess.

Last edited by Brontosaurus; 11-10-2016 at 03:30 PM.

Striving to be brief, I become obscure. --Horace

-

11-10-2016, 03:42 PM #38

Thank you for your comments. Hexagonal is not something that interests me right now, but to each his own. I have had my eye on the Fällkniven CC4, which is a small stone, so I'm glad to hear it mentioned. It is true that folks will move from larger stones in starting out with a progression, gradually moving to smaller stones in finishing. That is another avenue worthy of consideration, or for hypothetical discussion. I wonder if this has something to do with resistance of the stone, presuming that there is more resistance in starting out with the progression and less resistance towards the end.

Last edited by Brontosaurus; 11-10-2016 at 03:46 PM.

Striving to be brief, I become obscure. --Horace

-

11-10-2016, 04:35 PM #39

Again, I am not saying that the methods used to hone a knife should be used with the 4" x 1-1/2" hone example. Just that the razor would be approximately scaled to the stone as compared to the 8" knife example.

Again, my original premise was not necessarily entertained with the beginning razor honer in mind.

I agree that using a smaller/narrower hone may increase the difficulty, especially in starting out as you mentioned before.

Maybe I wasn't clear before. I was directly shown a honing method that involved bench stones, an 8" x 3" Norton 1000 and an 8" x 3" Norton 4000 combo, followed by a fairly wide coticule bout. I adapted this example according to my own circumstances and followed this example as shown before branching out in other ways. This has been a gradual process evolving over five years.

Time will tell. Let us recall that old barber's hones and Carborundums were generally small in size.

I agree that learning the rolling-X stroke is very important here. But in using the rolling X-stroke, one also can come to the conclusion that wider stones are not needed. There are two ways to take that example of marking out the larger stone to show that selected areas can be concentrated upon, as revealed by a dedicated accumulation of swarf there. One is that, yes, a narrow stone would not be needed. The other is that if one can concentrate swarf in a dedicated area like that, then a wider stone may not be needed.Striving to be brief, I become obscure. --Horace

-

11-10-2016, 04:44 PM #40Junior Member

- Join Date

- Mar 2016

- Posts

- 26

Thanked: 16

The "gradually moving to smaller stones" progession is always a good method to improve razors with minor geometry problems. The smaller stone will result in a smaller and much more controlled contact surface. If you make sure, the razor is always held perpendicular to the stone the X-pattern will provide a good refining and sharpness to razors that are more difficult to hone on a large stone. I use the smaller stones for refreshing razors and sometimes i get a better edge this way, that is how i find out which razors profit from this kind of progression.

33Likes

33Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote