Results 21 to 30 of 67

Thread: Black arkansas vs Translucent

-

01-10-2017, 09:22 PM #21

Longhaultanker was nice enough to offer to bring them across the border for me but I ended up buying from natural whetstone. Soft, hard and black in a 10x3x1" format shipped for a very good price and when asked about flatness I was told they lap them flat guaranteed before shipping them out. Which put a lot of my worries to rest. I also asked about their black translucent as they say it's there finest. I was told about a 200 US grit difference between that and the black but I'm sure the black will wear down fine enough to finish a razor on.

If their black isn't fine enough I'll order the black translucent from them. Such is life, move forward and be happy with what I get.

-

01-10-2017, 09:46 PM #22Senior Member

- Join Date

- Dec 2014

- Location

- Virginia, USA

- Posts

- 2,224

Thanked: 481

Whew, 10 x 3 x 1? That's one heck of a large hone. Looking at Natural Whetstone it looks like you did pretty good pricewise. I don't think those grit ratings are at all fair to the stones, as it supposes what the smallest grit size you can peel off and attach to a piece of sandpaper is. For our purposes the American Grit rating can be tossed out the window.

I'm sure you've seen it mentioned before, but these aren't slurry producing stones so the grit size doesn't have much bearing on the performance of the stone.Arkansas Novaculite stones are classified by specific gravity and not the size of the grain. The grain of the silica crystals that form Novaculite are essentially the same size, 3-5 microns, whether the stone is classified as Soft Arkansas or True Hard Arkansas. Using Specific Gravity Testing, Dan's Whetstone Company measures the density of their stones, that is the compactness of the grains bonded together. Therefore the harder stones would then have more grains than the softer stones. Since the grit size of Arkansas Novaculite does not widely vary, it is difficult to compare it with the grit sizes of man-made stones. Grit measurement standards for traditional man-made stones vary internationally. By U.S. grit standards, genuine Novaculite most closely relates to the 600-1200 grit size.

At any rate, if their black is the same density as a Dan's black, I think you'll be plenty happy with the edges it gives once you get the surface burnished up.

-

01-10-2017, 11:03 PM #23

Right! It's about gravity / density. If it is a translucent, it will be within the "gravity" specification. After that it's about burnishing.

SolitarySoldier: glad to offer since I'm up that way so much anyway.A little advice: Don't impede an 80,000 lbs. 18 wheeler tanker carrying hazardous chemicals.

-

01-11-2017, 12:08 AM #24

I have had a Dan's Black before so it will be fun to compare how they match up. Yes marshal I originally from Dan's ordered 12x2. So I will settle for 10x3 lol.

Leon I'll keep that in mind next time I need to avoid some insane shipping charges. You will be messaged

-

01-12-2017, 10:19 AM #25

I like using the translucent stone as the finisher.

-

01-20-2017, 05:02 PM #26Senior Member

- Join Date

- Sep 2014

- Location

- Bulgaria

- Posts

- 840

Thanked: 168

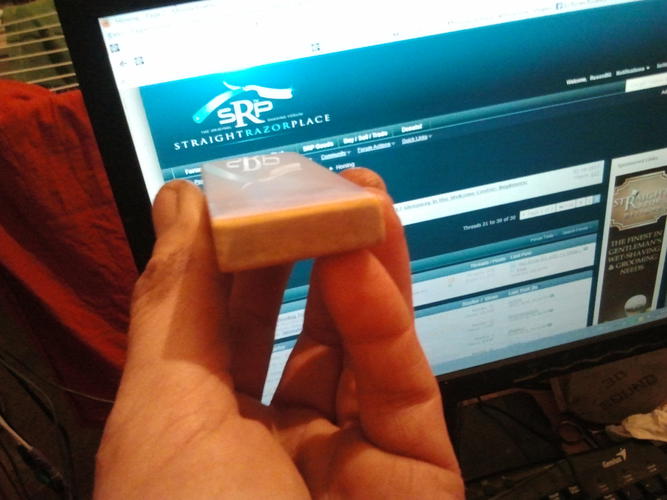

I touch up this morning a razor wth my new and only trans ark.

The afternoon i decide to relapp it at 1000 grit sandpaper and after i polish it on the buffing weel with fine alox paste

It looks like that now I cant wait to try it .

I steal this way from Glen - GSSIXGUN \ the buffing weel technique /

He is one of the most experienced and cool honners ive know

Last edited by RusenBG; 01-20-2017 at 06:21 PM.

-

The Following User Says Thank You to RusenBG For This Useful Post:

Euclid440 (01-20-2017)

-

01-20-2017, 07:40 PM #27Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Cool, please report on the finish it produces.

Also, can you explain the process, what grits did you use and maybe the how to.

Nice looking old stone. Cutting edge… as usual.

-

01-20-2017, 10:01 PM #28

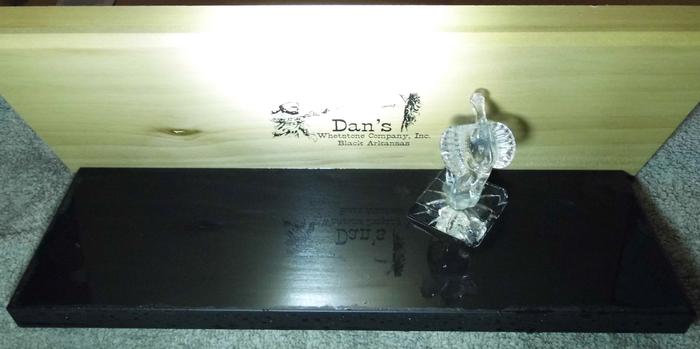

My surgical pitch-black (10"x3"). I like it very much, a bit thin but this is an advantage for me.

I like hand held honing with this large one and it only weighs 1.5lb. Abrasive wear? No chance! It is ultrahard and ultrafine. Perfect to use after an average Jnat finish if the edge could be better.

I use a good amount of soap in the water to prevent the stone to clog, seems to work very good. I have no translucent and so I can not compare but this one is superb. It was bought in late 2014 from Dans.

In the direct light there are some brighter lines visible but it is not a little translucent. The stone is deep black and the most homogeneous stone I have ever seen. After lapping with 1.2k w/d I used a very hard Coticule slurrystone and honed a bit with this slurry. Some scratches from lapping are still there but the surface is very smooth now and I get great edges.

Last edited by Sebrazor; 01-20-2017 at 10:04 PM.

-

01-20-2017, 10:52 PM #29

.

For you experienced Arkie guys, I'm thinking of trying this. I've got the trans ark I posted about a couple of weeks ago that is very finely-burnished already. Does it improve edges to buff the ark's surface on a wheel to an ultra-mirror level? Would that slow it down? Seems like I read somewhere that a too well-burnished ark surface has to be "refreshed" to start working again. I'm new to the ark and am still learning its secrets-inquiring minds want to know more about this.

-

01-20-2017, 11:06 PM #30Senior Member

- Join Date

- Dec 2014

- Location

- Virginia, USA

- Posts

- 2,224

Thanked: 481

General rule of thumb for Arkansas stones: More burnished = finer finish & slower cut. IMO when it comes to a finishing stone, "Too burnished" doesn't exist. That's more like, "Just right." But a soft or hard Arkie you want to cut a little faster, so when those get burnished it's time for a quick scuff & refresh.

-

The Following User Says Thank You to Marshal For This Useful Post:

ScoutHikerDad (01-20-2017)

140Likes

140Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote