Results 1 to 10 of 14

-

01-13-2017, 10:18 PM #1

Coti with logo and little AM hone

Coti with logo and little AM hone

I took a chance and bid on a dirty lot of hones. From the pictures I was pretty certain among them was a natural combo coticule and an AM Hone (Olean, NY). They arrived today and I was right!

The coticule looked like it had been used with oil, needed a cleaning a lapping. Cleaning didn't remove much of the gunk so I started lapping and a logo emerged. Looks like some sort of picture with "Razor Hones" underneath. Having a coti with a logo is neat and all but I feel like I'd rather have a flat lapped hone to use, but the logo will likely disappear if I continue. It measures 7" x 1 5/8" x 3/4".

There was also a little AM Hone from Olean, NY which looks like the "Exide" hone. It measures 3 3/8" x ~1 7/8" x 3/4". It has some gouges and some edge chips. Can I lap it?

Also, could anyone tell me if the AM hone is an "Exide" or weigh in on any reasons to keep the coti logo and not lap it flat?

Thanks for looking!

"Go easy"

"Go easy"

-

The Following User Says Thank You to xiaotuzi For This Useful Post:

Slawman (01-14-2017)

-

01-13-2017, 10:32 PM #2

I prefer to use my tools and if the logo would disappear that would just be part of life. To me those stamps are not a big deal. You could always make a new stamp....

-

01-14-2017, 12:54 AM #3< Banned User >

- Join Date

- Oct 2016

- Location

- Saratoga, CA

- Posts

- 597

Thanked: 59

Boy! That's back when a coticule was a coticule, not the 750 grit sandpaper garbage their selling these days. IMO ONLY!

-

01-14-2017, 12:56 AM #4

Coti with logo and little AM hone

Coti with logo and little AM hone

The barber hone looks like a Exide. Thats mine..this was a kind of sellers made version

Last edited by doorsch; 01-14-2017 at 12:58 AM.

███▓▒░░.RAZORLOVESTONES.░░▒▓███

-

-

01-14-2017, 12:59 AM #5

Take pictures to document the stamp...if you want to use the stone you need to lap it to good conditions...

███▓▒░░.RAZORLOVESTONES.░░▒▓███

-

01-14-2017, 01:31 AM #6

Thanks, doorsch. Yes, I will continue lapping the coticule and most likely lose the stamp in the process but I will take a few more pictures of it first and then I will have a nice usable hone when it's all lapped up.

Any thoughts on lapping the AM Exide barber hone? I often hear not to lap barber hones but this one is a little rough."Go easy"

-

01-14-2017, 07:27 AM #7

Coti with logo and little AM hone

Coti with logo and little AM hone

I personally didnt experienced to much ussues with that, but on the other hand many proposed to lap only when you have "real issues" with the stone. This includes deep scratches or gauges which would make it impossible to use the stone....

Iam not the master of Barber Hones, there are others around dealing deeply with this stuff. On the other hand i cant believe that something magical has been done to the surface that when lapping they cant be usable anymore and loose their properties.

They were made in a molding process with abrasives and a binder so in generally the piece should be containing one mixture, or two (when two different sides). Some instructions also say to clean the stones with emery cloth....

I would be interested if the topic of "surface prep" on Barber Hones is really that important. Sure i can be wrong here but what would be the argument that the surface prepared within the factory/producer cant be re-created when lapping those stones.Last edited by doorsch; 01-14-2017 at 07:31 AM.

███▓▒░░.RAZORLOVESTONES.░░▒▓███

-

The Following User Says Thank You to doorsch For This Useful Post:

xiaotuzi (01-14-2017)

-

01-14-2017, 05:39 PM #8

What I find interesting is the hone was obviously used but never lapped by whoever had it in past years. If it had been lapped previously the logo would have been gone when you got it. Testimony to the fact that flattening was not practiced by many people back 'in the day.'

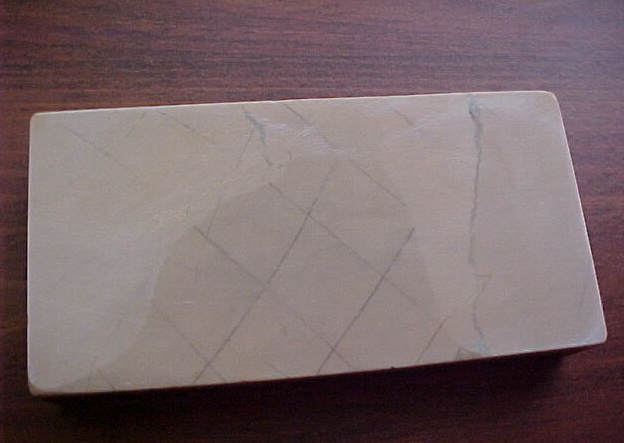

Speaking of which, I found this pic of a coticule that belonged to a barber in NY who worked from the 1920s into the '70s. Bought the stone from his son. See the remainder of the pencil grid showing how dished it was when I first got it and did initial lapping. Note that inclusion running across the surface to the right of the dished area, doesn't effect the honing.

There are two things to consider off the top of my head, one is that the old barbers didn't lap coticules let alone barber hones (in my experience) and the other is that some of them are on the verge of breaking down and disintegrating. I'm thinking you must have seen some like that where the binder, or whatever is beginning to fall apart, turn to powder ?

I've lapped a few and they were one helluva job. That is why I bought the DMT XX 120 micron. Utopian and ChrisL had them and said they were great for barber hones. Knowing what I know now I would just clean a barber hone with a scrub brush under running water with some dish soap. If it didn't absolutely need it I wouldn't lap it. YMMV.Be careful how you treat people on your way up, you may meet them again on your way back down.

-

The Following User Says Thank You to JimmyHAD For This Useful Post:

xiaotuzi (01-15-2017)

-

01-14-2017, 06:03 PM #9Senior Member

- Join Date

- Dec 2014

- Location

- Virginia, USA

- Posts

- 2,224

Thanked: 481

There are 2 reasons not to lap them. Resin bonded stones that are dried in the sun may have degraded beneath the surface. Some folks have found that once you break that top layer, the stuff beneath just crumbles.

The other, is that barber's hones are not made with a fine grit abrasive, like a Naniwa 8K. SEM photo of a Franz Swaty for example reveal that the cutting material is 300 grit particles, and the reason it behaves as such a good finisher is because those particles only stick up very slightly so that they do not make deep scratches in the blade.

A few quick scuffs with emery cloth to clean the black smudge off will likely not degrade performance. The binder is very hard so most of what that abrades away will be swarf. Attacking it with a lapping plate will eat away at the binder and expose a lot more of that large grit cutting material. You can burnish them and get the performance back, But I know from experience that takes a hefty amount of elbow grease. That stuff just does not like to break down. I think I'm getting close though!

I think lapping Barber hones, much like lapping a Black/Translucent Arkansas hone, is one of those things you only have to try once to realize why people say if - and only if - it's necessary.

-

01-14-2017, 06:53 PM #10

Well my approach was not to talk what would happen when you lap Barber Hones which due their age are falling down to pieces. We know that some of them are far beyond 50years and more. Thats a proper fact not too lap such Barber Hones and an argument i can follow. Also there are stones around which should not get in contact with water or they fall to pieces...having such Barber Hones where the Binder isnt working any more, those are also the ones you cant really use any more in a good manner...

@marshal:

I also can get youre point with only removing a minimal layer on top of the Barber Hone. Actually the fact that you will eat away the binder with a DMT is something i cant agree on...its a moulding process...the component has to be well mixed and homogenious. Sure we dont know how the processes were running in the past and ive see a lot of BH where the double sides werent build up equally and some werent bonded good enough together.

But what you wont have in many cases is a top working surface with the "good or fine" particles and lapping away 1-2mm resulting in bringing up big chunks of 300grit particles..could be that for the Swaty test youre mentioning and which i read over this is the case. Im sure many other BH have a different and finer composition. The receipes are available and some contained F1200 Abrasives.

Thanks for all youre views and discussion topics to this...███▓▒░░.RAZORLOVESTONES.░░▒▓███

47Likes

47Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote