Results 11 to 15 of 15

Thread: Franz Swaty restoration.

-

01-19-2017, 05:36 PM #11At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,063

- Blog Entries

- 1

Thanked: 13249

-

The Following 3 Users Say Thank You to gssixgun For This Useful Post:

Carlospppena (01-19-2017), Marshal (01-19-2017), xiaotuzi (01-19-2017)

-

01-19-2017, 06:10 PM #12

-

The Following User Says Thank You to AlienEdge For This Useful Post:

Carlospppena (01-19-2017)

-

01-20-2017, 03:12 AM #13

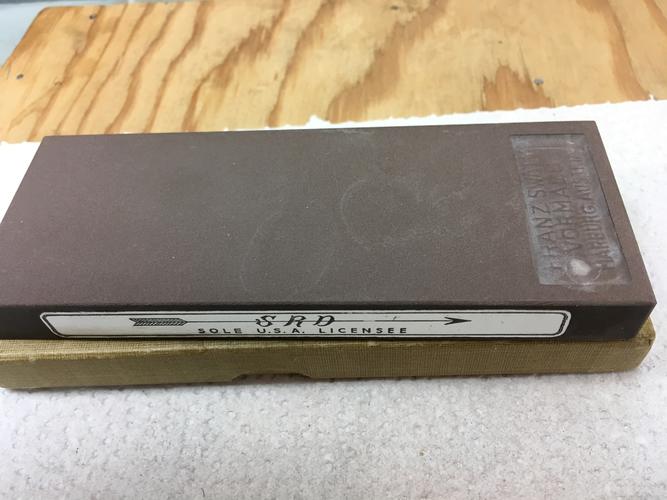

Here's the one that looked to me to be unused. Looking at it closer looks like it has dried water/soap marks on it which suggests it maybe was used at some point like with lather. Maybe "unused" was a bit too strong and it's more like barely used. The edges are crisp and it has an "SRD" sticker in near perfect condition on the side.

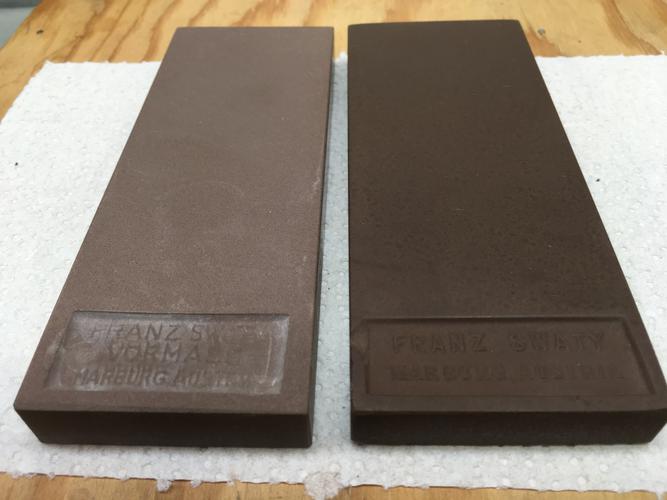

Here it is next to one that looks more typical to me. The SRD one has a "chalky" feel while the other has the usual shiny "waxy" feel.

I have not tried either one yet so that will be a first step so I can compare the two. Here's another one that is in worse condition that I would consider lapping/resurfacing, or at least addressing the issues along the edges.

I have a number of other barber hones, Swatys and other makers, mostly from flea markets and the like that are mostly in worse condition with pock mark type holes and gouges in the surface or larger chips etc. I might take one of those and do some experimenting with lapping and resurfacing if I can get some time together."Go easy"

-

The Following User Says Thank You to xiaotuzi For This Useful Post:

Carlospppena (01-20-2017)

-

01-20-2017, 03:24 AM #14Senior Member

- Join Date

- Dec 2014

- Location

- Virginia, USA

- Posts

- 2,224

Thanked: 481

Gonna agree that the SRD one just looks like it was used with soap and not washed so well. Mine's gotten that same chalky film a time or 2, but not nearly to that extent. Little bit of warm water and a scotch brite scrubbing and it should be fine.

The shiny one next to it kind of looks like it has oil or something on it. Might also be a candidate for a good scrubbing with scotch brite. Maybe after a good long soak in hot water to break some of that crud down.

The bottom one...that poor guy looks rough. Prime candidate for a lapping if ever there was one, but I've been wrong before. Hard to say for sure cause we don't know what's under the crud...At any rate, this is basically the method that I used:

How to lap a Barber hone.

Only difference was the initial lapping part. I got the barber hones long before I had a DMT or lapping plate. So they got lapped on 220 or 320 grit sand paper in a cookie sheet. And I skipped out on the petroleum jelly part. Might correct that oversight, if for no other reason than to be sure I didn't botch a step.

-

The Following 2 Users Say Thank You to Marshal For This Useful Post:

Carlospppena (01-20-2017), xiaotuzi (01-20-2017)

-

01-20-2017, 06:48 AM #15Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

The Swatys that I've owned have been consistent material on both sides. I have actually surfaced them coarser and finer on both sides, and both sides react the same. So yes, I can say with a fair amount of confidence that they are normally consistent in their makeup all the way through. I'd say the Swaty paperwork says exactly what I said in writing, right in the owners manual. A coarser surface will allow the hone to cut somewhat faster and a bit coarser, a finer surface will slow it down but cut finer. We aren't talking about a coarse surfacing making it into an 80 grit equivalent and a fine surfacing creating a 30,000 grit equivalent here. There is a small shift depending on surface prep, but it's not going to be a dramatic difference. Swatys are fairly quick hones regardless.

A Swaty should be hard as heck in terms of binder, and release basically nothing during use. If you ever see any autoslurrying or similar, your Swaty's binder is shot. The surface should work up to a glassy shine on the finishing side, not a matte finish.

-

The Following User Says Thank You to eKretz For This Useful Post:

Carlospppena (01-20-2017)

28Likes

28Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote