Results 1 to 10 of 12

Thread: Yellow Lake shenanigans

-

07-01-2017, 02:23 AM #1Senior Member

- Join Date

- Dec 2014

- Location

- Virginia, USA

- Posts

- 2,224

Thanked: 481 Yellow Lake shenanigans

Yellow Lake shenanigans

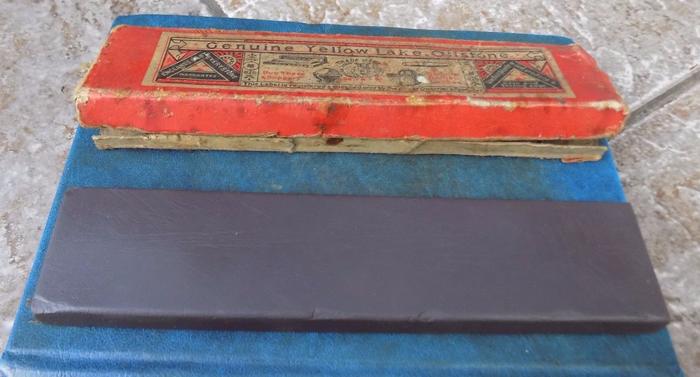

I mentioned somewhere a while back that someone turned me onto a Yellow Lake stone. Indications are it's from after Mr. Salmen sold the mine, but same stone from the same quarry. Authentic Yellow Lake slate Ebay Photo:

This is what it looks like after a Simple Green soak and half decent lapping. Still needs a few minutes of work on the lapping plate, but it's close to ready for polishing:

And this is what it looks like sitting atop AJ's Llyn Melynllyn:

The Yellow Lake seems to be a deeper purple, the slurry is what I would call violet. I'll get a better picture of that when I finish lapping it tomorrow. I'd wager they would be closer in color were it not for the skim coat of shave lather on the stone I got from AJ.

It has some rather deep scratches in it. Reminiscent of a child finding Granddad's sharpening stone in the shed and scraping it all to hell with a nail before anyone caught him. My inner codger wants to curse the little scamp for roughing up such a stone, but I decided that at least on one side I'll leave his markings in the stone. There probably aren't many Americans that can say one of their razor hones was 'decorated' by a young (and very bored) English boy. It gives the stone character.

I suppose after I get it suitably prepared I'll have to pick out a blade and do some testing. I'm thinking Morley Clover honed up up a Norton 8K, then I'll test the Original Yellow Lake VS my other 2 Welsh Slates. Should be an amusing way to pass some time.

-

The Following User Says Thank You to Marshal For This Useful Post:

Hirlau (07-01-2017)

-

07-01-2017, 02:27 AM #2

Nice rock, Marshal-You gonna burnish it to where you can see your reflection? Or does that type of slate need some tooth in the finish?

-

07-01-2017, 02:40 AM #3Senior Member

- Join Date

- Dec 2014

- Location

- Virginia, USA

- Posts

- 2,224

Thanked: 481

That's a good question...and one I don't have a ready answer for. I like the results I got polishing the stuffing out of my other slates. But the back side of them that I use with slurry still has tooth since they were unmarred new stone and finishing the surfaces differently was an option.

This one didn't come with a slurry stone, and I want to preserve the scratches, so I was just going to polish the one surface like I do just about everything else. Testing it versus my other polished slates without the same treatment wouldn't exactly be fair.

But for kicks and grins I could pause the polishing process at certain intervals and do a quick touch-up/test shave with something to see what (if anything) happens. No harm adding more experiments to the game plan.

-

07-01-2017, 01:17 PM #4

Could have been used to sharpen darts.

-

07-01-2017, 04:39 PM #5Senior Member

- Join Date

- Dec 2014

- Location

- Virginia, USA

- Posts

- 2,224

Thanked: 481

I'm going to opt to continue believing my little scamp narrative. Partly because it brings back fond memories of mischievous things I did as a kid, partly because if those gouges were made by darts I pity the poor projectiles. Those digs are pretty deep and I can't imagine it resulting in anything but dulling whatever made them.

-

07-01-2017, 05:22 PM #6

I'm glad you like the stone. I prefer your narrative as well.

Sent from my iPhone using TapatalkEnjoy the day,

Benson

-

07-01-2017, 09:46 PM #7

The scratches might be from sharpening fish hooks, though usually you see something like v-shaped grooves on or near an edge. Maybe an incompetent fish hook sharpener? Lol.

Cheers, Steve

-

07-01-2017, 10:59 PM #8

-

07-02-2017, 03:26 AM #9Senior Member

- Join Date

- Dec 2014

- Location

- Virginia, USA

- Posts

- 2,224

Thanked: 481

Considering the erratic nature of it it just looks like the handiwork of a kid scratching a stone rather than someone intent on sharpening anything. Though at one end there's about a half inch groove that might've been a lot of intentional back & forth rubbing. Who knows? I've doubts anyone will pop up with the backstory for those random scribbles.

I tinkered with it today, got it lapped flat with the plate. Then I worked it up to 1K with sand paper. At that point I took my trusty Gold Dollar test bed razor and honed it up to 8K, and transitioned to 125 laps on the Yellow Lake using pure water. Pretty much just a side grade at that point. Maybe a little more comfortable, but otherwise more or less an 8K-ish edge.

I tried the same thing at 2K. 30 laps on the Norton 8K, 125 on the Yellow Lake. Can't say the results were all that much better. Maybe a tic keener but nothing to write home about. Brushing it across the Norton 4K is where it started to show some difference. Back to the 8K for 30 laps to re-zero the blade, then another 125 on the 4K polished Yellow Lake using plain water. Not a huge step up from 8K, but an noticeable improvement in polish and keenness.

The magic really happened after polishing it with the Norton 8K. Zero'd the razor on the norton with as many strokes as before, then did the same routine on the Yello Lake with just water. 125 laps later I had an edge somewhere between 8 and 12K that was respectably sharp. I'll probably finish polishing the hone tomorrow with CrOx and a cotton wheel, then give it one final test run. But so far the more polished/burnished it gets the finer the edge it creates.

Edit: Almost forgot to mention stropping. I did strop the first test 25 on linen, 50 leather. The rest of the tests I just shaved right off the stone. So I'd say it was all around a little on the uncomfortably keen side of things, but when you don't strop you kind of ask for that. All things considered though, it's shaping up to be a solid finisher.Last edited by Marshal; 07-02-2017 at 03:32 AM.

-

07-02-2017, 06:30 AM #10Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

Marshal, I will share another trick I've used with some success for "burnishing/smoothing" stones in the past also in case you might like to try it on this one. Find yourself a piece of tungsten carbide (often used for cutting steel in machine shops, can be had for peanuts on eBay) something like this one:

The above piece is about 3/4" square and 1/4" thick -

but if you get one get whatever you can find that's a good size for you. Use it to burnish the surface of the stone after it has been lapped flat. This works even faster than using steel like a chisel or something, and smoothes the stone even more. A side benefit is that the stone will not change the flatness of the tungsten carbide because it's not hard enough to cut it - and the T.C. will be flat to begin with as they are ground flat from the manufacturer with a diamond wheel. This works extremely well and quite quickly.

-

The Following 3 Users Say Thank You to eKretz For This Useful Post:

BWH1980 (07-02-2017), Marshal (07-03-2017), Toroblanco (07-02-2017)

17Likes

17Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote