Results 1 to 10 of 12

-

08-22-2017, 09:13 PM #1Senior Member

- Join Date

- Jul 2012

- Location

- Mooresville NC

- Posts

- 742

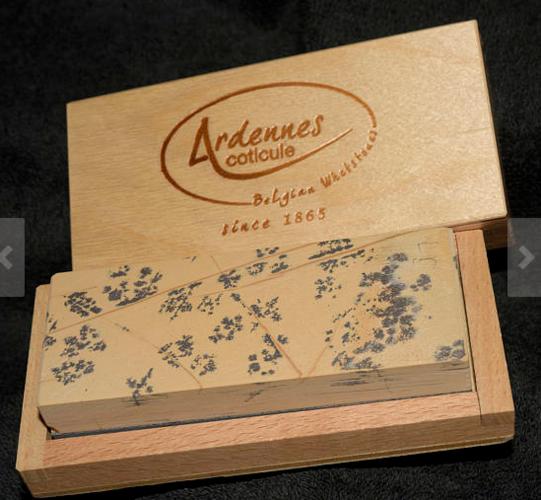

Thanked: 133 Saw a crazy looking coticule on the web, thought I would share.

Saw a crazy looking coticule on the web, thought I would share.

Was trying to find some information on an item so was looking through sold items and I ran into this awesome looking coticule. It is not for sale and I don't know who owns it but I thought this thing looks crazy so thought I would share it. If I saw a coticule like this I don't think I could stop myself from getting it.

I really like how manganese looks on cotis. Would say my next favorite looking hone would be any jnat with nice Renge

-

The Following User Says Thank You to Christian1 For This Useful Post:

Marshal (08-22-2017)

-

08-22-2017, 09:23 PM #2illegitimum non carborundum

- Join Date

- Jan 2008

- Location

- Rochester, MN

- Posts

- 11,552

- Blog Entries

- 1

Thanked: 3795

I agree. I would buy it without hesitation. Of course, I feel that way about most coticules. Aside from the mottling, look at how thick it is!

-

08-22-2017, 10:04 PM #3

Apparently, red lines are good. Congrats to the owner.

Striving to be brief, I become obscure. --Horace

-

08-22-2017, 10:11 PM #4Senior Member

- Join Date

- Jul 2012

- Location

- Mooresville NC

- Posts

- 742

Thanked: 133

Not really sure how great of stone it was but looks nice. I think it was a 4"x 1.5" stone but not sure, I would of used it either way though

Last edited by Christian1; 08-22-2017 at 10:14 PM.

-

08-23-2017, 02:50 AM #5

I got 2 of those, they were given to me. Haven't tried them extensively. They are really hard stones, hardly any slurry.

This is not a typical corticule. As you can see it is much thicker than an ordinary coticule, does not need a slate backing.Plus ça change, plus c'est la même chose. Jean-Baptiste Alphonse Karr.

-

08-23-2017, 06:24 PM #6Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459

It looks like it has one, anyway, though. I'd imagine that the hard layer benefits from having the slate for stability.

I've only had 5 coticules (out of several hundred stones total), but one of them cracked on me - an old deep rock hone - after doing nothing other than using it and keeping it in a climate controlled area. I'd be afraid to keep one without a backer - at least if the backer is there, the crack will terminate at the glue line.

Interesting looking stone ,though.

-

08-23-2017, 06:24 PM #7

A karasu coticule

I saw it when it was for sale as I tend to spend a lot of time browsing that site. No coticules for me yet, never tried one. Maybe one day.

I saw it when it was for sale as I tend to spend a lot of time browsing that site. No coticules for me yet, never tried one. Maybe one day.

-

08-24-2017, 12:07 AM #8Sharp Minded Citizen

- Join Date

- Oct 2013

- Location

- Bucharest

- Posts

- 434

Thanked: 156

oh that's a deligtfull coticule...

I like the way the Manganae is evenly distributed throuougt the layer.

That's always a good sign provided 2 other factors also are present.

Manganase catalizes quartz transformation into spessartite christals in the presence of pressure.

The amount of presure determins the size and mean distribution of spesartite christals....same as gass bubbles in mineral water increase in volume as pressure is released and decrease in volume when presure increases...in the same way...a coti exposed to pressure usualy has smaller sized garnets and of more similar size.

Also the overall density of the stone increases from pressure so the calcite matrix gets compacted and denser yelding a harder stone.

Higher pressur is usualy found in deeper layers...thus the Brand Deep Rock...and many others that used to pride themselves in deep layer cotis.

Now you can have pressure and manganase all you want if you dont have the substract for spessartite formation....quartz.

Depending on condition and catalists quartz can christalize in a wide variety of shapes and sizes...we are basicaly talking of silica here.

Manganase just hapens to promote transformation to spessartite in the calcite matrix under pressure.

Now the amount of quarts in the calcite matrix is very important...

Too less and you get a slow stone....like the La Dressante au Bleu Layer...

Too much and it can ruine the hone in more ways. Best content by volume of quartz should be between 20-40-45%max

This depends on the manganase/quarts ratio that is present in the calcite matrix and pressure ... and there are only a few possibilities...

1) High pressure + quartz 20-40% + manganase more then sufficient to catalize transformation

These are the conditions that yeld high quality coticules.

These stones are usualy dense, with finely grained and evenly distributed spessartite christal/garnet size.

The manganase catalisez the quartz transformation ant the excess forms lines or spots depending on how tightly packed the calcite matrix is...usualy a tighter packed matrix squezes the manganase into lines...a less tight packed matrix is prone to yeld spots of manganase. The amount of manganase left over after transformation is complete also has an effect on how it will organise...Higher quantities left over tend to yeld dense black spots rather then lines.

Coticules that have both spots and lines of manganase are extremly rare.

These stones are usualy fast cutters on slurry and due to the fat that they are hard and have a densly packed calcite matrix they releas garnets slowly...thus on water they are slow cutters and great polishers.

Finishing under running water does not improve the laping capabilities of these stoes by much.

2) High pressure + quartz 20-40% + less then needed manganase.

These stones are extremly hard due to the fact that untransformed quartx tends to form a web in the matrix reinforcing and stabilizing it.

Depending on the amount of manganase and the amount of quartz transformed to garnets these stones can be faster or slower on slurry but they tend to be slower on water due to low slurry release.

If too much of the quartz is left in the web like state it can even be seen as shiny lines when you look up into light at the surface of the stone.

Manganase spots or lines are not present because the low quantity present has all been used up in the transformation.

Slurry is usualy hard to raise and theyr speed on slurry depends grately on the amount of garnets.

Speed on water is usualy slow due to slow garnet release.

Friction usualy increases when hitting a spot that is densly packed in untransformed quartz.

3) High pressure + quartz < 20% or >40% + Manganase more then sufficient to catalize transformation

In the <20% quartz variant...the stone is usualy hard and slow with manganase deposits of lines or spots depending on how tightly packed the stone is.

In the setting of >40% quartz and suficient manganase ... the matrix gets saturated with garnets to the point it becomes fragile.

Had stones that are prone to exfoliation...cracks.

Exceptionaly fast stones both on slurry and water with chrisp slurry ...slurry feels like sand under the steel because it is released in clusters.

Water only is fast...tends to release slurry although hard stone.

4) High pressure + quartz < 20% or >40% + Manganase less then needed.

In the <20% quartz variant ... Hard slow stone...no manganase deposits...although slurry may be released it has low cutting power and gets dull quick.

In the setting of >40% quartz... very hard stone with no manganase deposits...quarts is mainly setup in a web pattern in the calcite matrix...slow slurry release, slow cutting power, lots of friction between the steel and blade but low cutting power...these coticules are usualy burnishers.

5) Low pressure + quartz 20-40% + manganase more then sufficient to catalize transformation

Softer stones...fast cutters on slurry due to faster slurry release, manganase deposits are present but more frequent spot patterns occur.

Fast cutters on water due to slurry release.

These stones benefit from finising under running water....for washing away the released garnets.

In the event that pressure is not sufficient irregular shaped garnets may occur.

Irregular shaped aspherical garnets tend to promote slurry dulling and dont go well with circle motions.

These stones benefit grately form simple X passes under running water.

Avoid circles.

6) Low pressure + quartz <20% or >40% +manganase more then sufficient to catalize transformation

In the <20% quartz variant these stones are usualy softer with manganase inclusions in the form of spots.

Soft slow cutting stones on slurry and water.

These stones benefit from finising under running water....for washing away the released garnets.

In the event that pressure is not sufficient irregular shaped garnets may occur.

Irregular shaped aspherical garnets tend to promote slurry dulling and dont go well with circle motions.

These stones benefit grately form simple X passes under running water.

Avoid circles.

In the >40% qurtz content variant ... these stones are softer, fast cutters on both slurry and water due to fast slurry release...

They tend to be anoingly fast cutters.

...manganase inclusions in the form of spots.

Soft fast cutting stones on slurry and water.

These stones benefit from finising under running water....for washing away the released garnets.

In the event that pressure is not sufficient irregular shaped garnets may occur.

Irregular shaped aspherical garnets tend to promote slurry dulling and dont go well with circle motions.

These stones benefit grately form simple X passes under running water.

Avoid circles.

7)Low pressure + quartz 20-40% + manganase less sufficient to catalize transformation

Medium hardness stones do to quartz web formation, speed may vary by the amount of quartz that has been transformed into garnets.

No manganase spots or lines present.

Quartz web may be present increasing the stones relative hardness and it's friction against steel.

8) Low pressure + quartz <20% or >40% + manganase less sufficient to catalize transformation

<20 quartz content .. soft- medium hardness stones due to quartz web stabilizing the calcite matrix...

Slow cutters on slurry and water with friction between the stone and steel but less pronounced.

>40% quartz content...hard stones...rich quartz web in the matrix that stabilizes the stone...

Lots of friction between the steel and hone...

Poor slurry release...poor cutting power...burnisher

Aside from these combinations resulting from the 3 essential elements required for coticule formation...there are other elements that may factor in...like

Inclusions

Aside from the calcite mtrix, manganase, and quartz that make up the coticule other elements may be present and my or may not affect the stone's performance looks and integrity.

I will try to list some of the more important ones.

Iron lines and iron oxide lines.

Iron oxide lines manifest themselvs as light orange or red lines in the coticule layer and may also be found in the BBW layer.

The reason they are important is they can affect the integrity of the stone and promote cracking.

Iron lines are usualy metalic grey...when exposed to water and air iron ofidizez forming redd feric oxide aka rust.

Rust ocupies larger volume per unit then iron...thus it exerts a pressure effect on the stone promoting cracking along the deposits of iron that oxidize.

Now depending on the time the iron oxidized compared to the stone formation...they may be safe or unsafe.

If the iron oxidized before the coticule formation and the matrix was presurized after it oxidized...they should be safe.

If the iron was present in the matrix with no oxigen and it began oxidizing after the stoe was mined and cut...then there may be a probelm.

Other metal oxides.

There are many more metals that can pop up in coticule stones and some of them form oxides as the stone forms.

Some of them give the stone it's coluors...for example the La Dressante Upper layer is a layer that frequently manifests all sorts of colour hues and lushes...

La verte is another example...

La gross Blanche and the fact that it exiits surface oxidation when exposed to light also is a good example of other inclusions.

There are many aspects that factor in making a good coticule ... especialy a high quality razor hone...I hope this info will help many of you better understand the stones you have.

It took me a few years of research and over 50 coticules to begin to understand and apreciate these stones fro what they truly are.Last edited by ovidiucotiga; 08-24-2017 at 12:29 AM.

-

-

08-24-2017, 12:30 AM #9

Nice write up, ovidiucotiga. Thanks for the explanation of the different formations. I think one of my coticules is like example #1. Lines of manganese, fine grained slow cutter on water and fantastic polisher.

"Go easy"

-

The Following User Says Thank You to xiaotuzi For This Useful Post:

ovidiucotiga (08-24-2017)

-

08-24-2017, 12:49 AM #10Sharp Minded Citizen

- Join Date

- Oct 2013

- Location

- Bucharest

- Posts

- 434

Thanked: 156

Like i said before there are many factors that dial into a coticule beeing born and one must understand this in order to know what stone to search for.

For me after going trough 50 or more coticules buying testing and selling ... i ended up keeping only 3...although at one time i had 20 or so in my collection.

The one i love the most is rare example of La Dressante Upper Layer.

Ironicaly my best coticule is a contempornly mined stone glued to slate...another example tha coticule is coticule no matter if vintage or contemporanly mined.

I say it is a rare exmple of La Dressante Upper because these stones have wide variations in base quartz content and manganase content although the layer is usualy one of the finer grained layers...speed and hardness may vary.

I am lucky enough to have an exeptionaly hard La Dressante Upper Layer that is fast on slurry and slow on water.

Garnet content is in the 20-40% range but closer to 30% from my experience.

What is exceptional about this stone is that garnets are extremly fine grained and of similar size and shape ...and yelds a homogenous scratch pattern...working well on slurry and plain water.

40Likes

40Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote