Results 1 to 10 of 18

Hybrid View

-

08-27-2017, 09:47 PM #1

Another budget Chinese(??) finishing hone

Another budget Chinese(??) finishing hone

I wanted to create a standalone post for this hone. A previous post took a turn and someone mentioned this hone:

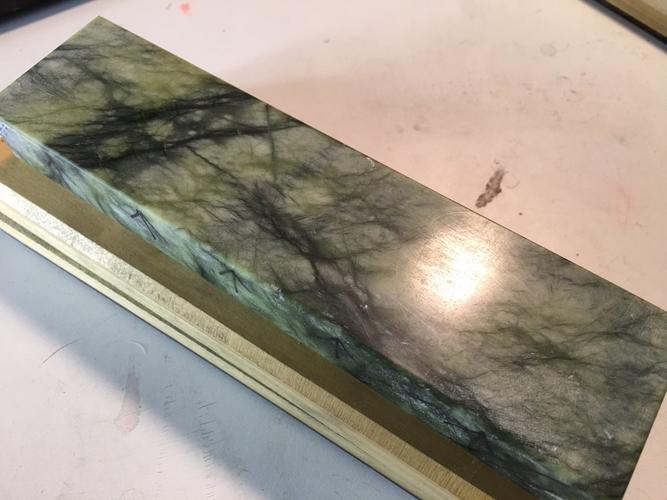

Home Beyond Natural Green Polish Oil Stone Knife Sharpener M99G 10000# Whetstone

I purchased one just for how it looked LOL and was pleasantly surprised with the performance. It came lapped really close to flat and had a fine coating of oil on it. I cleaned it up and lapped it on my 400/1000 CKTG diamond plate and then followed up with a well-worn piece of 1000 grit w/d sandpaper.

It provided a very crisp clean edge and the scratch pattern looks to be between 10-12K. Not quite as fine as my PHIG (CH12K) but still very nice and very capable of a one pass shave.

As long as they can keep providing consistent rocks, this could be a very good value finisher.

Last edited by kelbro; 08-28-2017 at 12:27 AM.

-

The Following User Says Thank You to kelbro For This Useful Post:

randydance062449 (09-21-2017)

-

08-28-2017, 12:21 AM #2

What was your honing progression and what steel did you hone?

-

08-28-2017, 12:37 AM #3

No progression. It was just a touch-up on an older Hart Steel that was shaving OK when I put it away but needed a little attention. The steel in that razor is very hard and a good honing lasts and lasts.

In a synthetic progression, it would really clean up a Norton 8K edge and you most likely wouldn't need to go any further.

In a natural progression, I would use this one to follow a hard ark or coticule.

Also, I only tried Smith's honing solution which tends to allow me a little more cut than polish. Might get a little better polish using glycerin or Norton's mineral oil.

-

The Following User Says Thank You to kelbro For This Useful Post:

Geezer (08-28-2017)

-

08-28-2017, 01:00 PM #4

Wanted to add that it did release some slurry with just a little effort when rubbing on the sandpaper. About the same amount as my CH12K. Quite a bit more than an Arkie would so I'm thinking that it's probably not novaculite.

-

08-28-2017, 03:28 PM #5Senior Member

- Join Date

- Jul 2012

- Location

- Mooresville NC

- Posts

- 746

Thanked: 133

Definitely cool looking hone.

-

08-28-2017, 05:56 PM #6

Keith already did a review for those as far as i remember....

https://youtu.be/P5q1DymKUvU███▓▒░░.RAZORLOVESTONES.░░▒▓███

-

08-28-2017, 07:22 PM #7Senior Member

- Join Date

- Jan 2015

- Location

- mountainside North Alabama

- Posts

- 129

Thanked: 14

I wonder what type of rock? sedimentary, metamorphic ?? looks almost marble like.

OK the utube link above says Beryl. hmmmm

-

08-28-2017, 08:13 PM #8Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459

His stone must be different than the one I got.

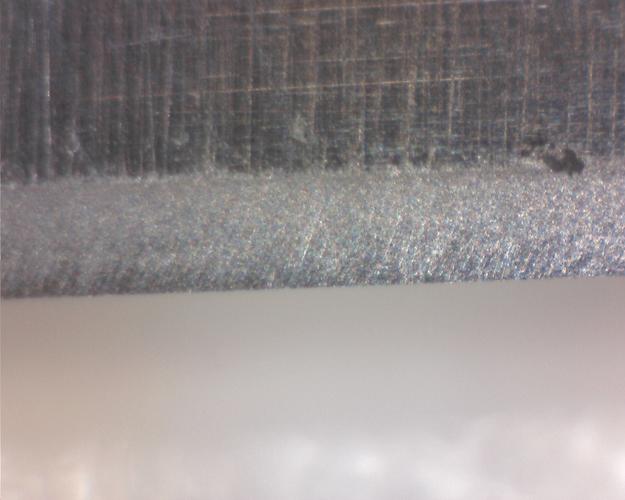

See the bevel pictures here. The edge isn't completely finished, I'll concede, but it's almost devoid of the prominent scratches that you can see from the other stones in this thread (including a bone colored trans and a jasper that also burnishes, but imparts stray scratches here and there).

http://straightrazorpalace.com/hones...ml#post1350243

The razor does need to come to it nearly finished, though, but if that's a problem, one could use both sides of it. Sprinkle diamond powder on one side (1 micron or so) and use the other side with nothing.

I recognize the guy in the video. He made the comment once that a stone that he was using wasn't an ordinary black arkansas, but a "surgical black arkansas" instead, which is a statement that makes no sense (there is no extra grade of black called "surgical black"), and blew up when I pointed that out. None of us knows as much as we think we do (including me), but when someone is selling something, the reactions seem to be different if they're corrected.

I have the old one in this thread still, as well as one of the $27 hones that were up a while ago. I will condition the latter and compare the two and post pictures at a later date. Not implying someone should spend money on anything, but I'm sure the one that I have will easily finish a razor if it's used properly (which due to the slowness may mean using it with some pressure and not being so deliberate on the strokes).Last edited by DaveW; 08-28-2017 at 08:15 PM.

-

08-28-2017, 09:01 PM #9Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459

FTR, even though my hone does look a lot different, I got it on ali express back when ali express was new (those hones were about $83 or something shipped at the time, and that's what I paid).

I am curious now, to see if my experience with the second stone is similar to the first and similar to the OP on this thread, that the shave is comfortable. I do remember expecting little out of the shave from the last one and finding it strangely smooth without being dull. Like coticule feel, but better than coticule. Several years removed, I understand now that these slow stones need to be worked with some pressure before lightening the strokes in order to actually finish an edge, so I think I can better the edges shown in that thread by a good bit. The consequence is that some are past the point of comfortable, though (last night's experiment with a new piece of japanese stone resulted in an extremely close shave and a few weepers. I think this stone is probably capable of that as long as it doesn't release a particle here and there. I made mine stone dead by trying tools on it first, though, which is what i wanted it for. It's too slow for tools).

-

08-29-2017, 03:30 AM #10Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459

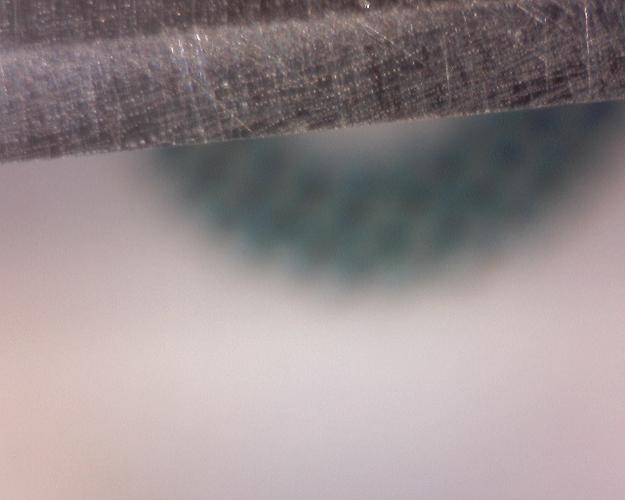

My version of this stone compared to an aggressive, but very fine jnat. English "bengall" razor.

First, the jnat (this yielded an extremely keep edge, almost too keen - weepers. The microscope picks up the tiny scratches, but you can see by the evenness of the edge that these are superficial. this is a very thinly ground razor, so the bevel is actually very small. No clue about actual magnification because the microscope is inexpensive and their claims are not accurate. It's probably really somewhere around 100x..not sure.

And then after indiscriminate rubbing on a (possibly mildly contaiminated) green stone that looks a little different than the recent ones, but it's out of china. Settled in due to use.

Apologies for the light amount of oil on the bevel.

The edge is still quiet, similar to the jnat. The grooves reduced. HHT with a familiar hair suggests the shave will be very keen.

The one thing that strikes me about this hone is that you first break it in, and then you have to be willing to use a little pressure on it. YOu can commit a major foul in the process if you let the razor get over the edge of the stone. no light x strokes, this stone is too slow for that, the bevel needs to be worked on it, which invites the danger of a big nick due to a contaminant or a mental error in not keeping the razor dead nuts on top of the stone.

Will shave again with this razor tomorrow night.

(both edges are after stropping with leather, which in my experience generally makes the edges look a little worse because it can break off the foil at the edge unevenly).

22Likes

22Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote