Results 11 to 20 of 20

-

11-26-2017, 06:40 PM #11Senior Member

- Join Date

- Jul 2012

- Location

- Mooresville NC

- Posts

- 741

Thanked: 133

coticule actually does have few small crack on the surface in the magnese line. Was thinking of using some CA glue. Although I have some glycerine at the house I will try out. Maybe I will just save playing with oil whenever I decide to grab a finishing arkansas (wanting a surgical black over trans and like a 6x2 size, but I have enough toys atm).

-

11-26-2017, 06:49 PM #12

Certain old coticules came with a label that said use with water, lather, or oil. Harder coticules seem to work better with oil than softer, auto-slurrying coticules from my experience. As for the oil type, you could use a dedicated honing oil like Dan's, Norton or Sharpening Supplies food-safe mineral oil blend, or even olive oil. I actually prefer to use oil with stones, rather than water, finding oil to be less messy.

Edit: If the stone has a crack, then oil will be beneficial as it tends to dampen the stone; water, rather, tends to advance the fissure. A crack on my soft coticule is why I started to use it with oil.Last edited by Brontosaurus; 11-26-2017 at 06:54 PM.

Striving to be brief, I become obscure. --Horace

-

The Following User Says Thank You to Brontosaurus For This Useful Post:

Christian1 (11-26-2017)

-

11-27-2017, 12:40 AM #13Member

- Join Date

- Mar 2016

- Location

- indiana

- Posts

- 54

Thanked: 9

Tried it, liked it a whole bunch. Using WD40.....so thin you can slurry with it. I have an aversion to water touching anything I'm sharpening, guess I'm a just a greaser at heart. I think it comes from machining on steel parts at work and coming back after the weekend and seeing the thing you worked so hard on has turned red....Oil is ingrained for me.

-

11-27-2017, 02:29 AM #14

I inherited my GGF's Coticule, back then it was darkened and water would just bead off, posting pictures of it on the forum I was told the stone was probably heavily used with oil.

I lapped it and it cleaned it right up, looking back now I wish I hadn't done that and wish I had left it as original as possible, ah well.

So even if you really worry, a quick lapping will take care of it.

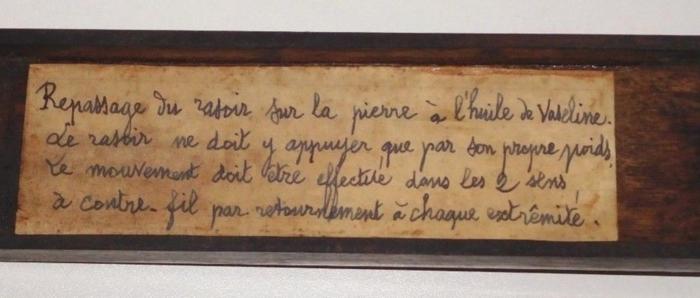

I've seen pretty old Coticules that came with hand written notes from owners / users that said to use it with oil, or 'vaseline oil' in a french written note

Here's one that came with a Coticule, says in french to use it with oil and only use the weight of the razor, no added pressure

-

11-27-2017, 08:17 AM #15

Yes many discussions and opinions.

There is a third option for a Coti so:

1) water, 2) oil or 3) running water (even running oil).

Because we are discussing finishing stones running water to eliminate

any slurry produces a very different edge then if a self-slurry is allowed

to build up even a little. Try ten final hone strokes under running water

on the last hone.

Water and oil are basically used to keep the stone from clogging with

swarff (mix of steel and stone powder) . Too much swarff (debris or waste) and the stone

can stop cutting a little or a lot. So for a hone to cut steel it needs something

to keep it clean enough.

For a finisher allowing the rock to clog up a bit or even a lot can make it abrade a log gentler than

it would if it was clean. This can produce a smoother edge in some cases. Older carbide hones

like the 101 were often loaded with Vaseline to improve their "finishing" qualities.

The coticle is often used with a dilution slurry process starting with slurry and then diluting that slurry

constantly to the point of clear water. In the extreme the clear water step can be

followed with a running water step.

So for a razor that shaved yesterday but just a bit rough one might touch it up (re finish it)

under running water. Alternatively the hone can be allowed to collect swarff even to the

point of glazing over to finish/ maintain an edge.

Oil goes bad... machine shops pay dearly for cutting oil and replace it quite often so it does

not do bad things to people and machines. Rancid oil is acidic, sticky and gummy.

If oil is used the oil needs to be replenished to keep it from going off. Old school oil

could be animal, vegetable or less likely petroleum. Old is not so old in this sport of

shaving so opinions can have formed from who knows what oil.

Since cotis have been used for centuries all manner of oil would have been tried

and the bad ones could not be removed then for want of modern detergents and solvents.

A water based honing solution like Smiths would hold slurry of a self slurry and rinse from

a coti in the dilution steps. But finishing does not need the quicker steel removing slurry

steps and I would finish or refinish under running water.

If that did not refinish the edge I would allow some self slurry action and

if that did not I would reach for a Shapton or slurry stone perhaps with Smith's

magic solution.

Finishing is a black art. You can begin to see the eyes of a hone master almost glow

when switching from bevel setting and honing to final finishing. The room gets a bit

quieter, hearts beat slower, voices get calmer sharpening is over and finishing happens

but not until it is time.

Oil does prevent rust... rust bothers an edge, strop dressing has some oil

in it so visit a strop if the last rock was not oiled before putting the razor up.

Oiling razors today is easy ... pick a people safe oil that is safe for your scales

and apply almost none. WD-40 has its place ;-)

-

11-27-2017, 10:54 AM #16

-

The Following User Says Thank You to Brontosaurus For This Useful Post:

TristanLudlow (11-27-2017)

-

11-27-2017, 11:28 AM #17

Aha nice, I was wondering about that a bit, thanks for clearing that up!

I find notes / or carved initials, numbers in razors or scales, etc etc all very interesting, adds to the fun aspects of our hobby

Very good point, that's why I regret lapping my great grandfather's Coticule, it seems it had taken decades to the state it was in, the surface was smoothed out by clogging and being used by oil.

Something I could replicate, but since there was no running water during his time that seems like a very convenient no mess alternative nowadays

-

11-28-2017, 11:16 PM #18Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

It isn't so much clogging of the stone that makes it cut finer, it's mostly the rounding over of the peaks/points of the abrasive particles in the stone. On most stones this happens much faster when using water than when using oil - as the coefficient of friction with water is much higher than with oil - so the stone wears faster. In effect, the particles dull with use.

-

12-03-2017, 02:10 PM #19Senior Member

- Join Date

- Dec 2014

- Location

- Virginia, USA

- Posts

- 2,224

Thanked: 481

Yeap. I'm of the opinion that a stone, coticule in particular, ought be used as-s prior to modification these days. Sitting back and mulling it over, there's a pretty noticable difference in the way my coticule behaved after being simply flattened up with my DMT 327 vs having spent hours trying to round over those roughed up particles, and then larger difference still after yet more hours of scrubbing the surface with the slurry stone to gently abrade away the ones that were damaged by the DMT and smooth the stone further still.

Mine was bought new from Ardennes, perhaps I would've been better served to use the stone as it came. After my first round of flattening it didn't feel like a finisher at all. Slowly over time I was able to smooth out the surface and make it work as I surmise it would have as it came from Ardennes. If someone spent years with oil on their stone and shaving off the results you might well wreck a perfectly good honing surface (if finishing is what you're after) by lapping it flat first then giving the stone a trial run.

But this is off topic. I use mineral oil on my coticule, cut with mineral spirits. For finishing we're using less pressure and generally want a finer/thinner oil. Ballistol, WD-40, mineral oil thinned up a tick with something etc. I also use a slick/thin shave lather, and just water on the same stone as I'm still playing with it to see what it likes. You're not going to hurt it with water, oil, or soap. If you use oil, just give it a wipe down with mineral spirits when you're done and no one will ever know there was oil on the stone. IF you get a stone that was used with oil and you want the oil off it, chuck it into a bucket of simple green and let it soak for a few days. 3 or so. I've removed some fairly heavy oil from old stones that way. You can't tell the difference between my Yellow Lake stone that was likely used for decades with oil and my Purple Slate from AJ on Ebay that's never had a drop of oil on it. If it's non porous the oil won't soak in deep, if it does soak in a few days in simple green or some light lapping will take care of the problem.

-

12-03-2017, 02:29 PM #20Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

Yes there are many variations to the ways that can be tried to get the best performance out of a stone for a specific purpose. Diamond lapping can be detrimental to certain stones for sure - in the context of producing good razor edges I mean. Others work great with a diamond plate lapping. Some need slurry stone rubbing, some need wet/dry smoothing, some need loose grit lapping...etc. etc.

40Likes

40Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote